“`html

Capable of enduring repeated compressions without altering their form, woven materials may be utilized to create robots, exoskeletons, automotive components, architectural structures, and beyond

Inspired by the ancient art of basket weaving, engineers at the University of Michigan discovered that woven materials revert to their original form following multiple instances of strong compression, while continuous sheets made from the same material become permanently deformed.

The modular framework to construct woven corners highlighted in Physical Review Research could be applicable in any area where both robustness and resilience are crucial, such as soft robotics, automotive components, and architectural materials.

After lead author Guowei (Wayne) Tu, a doctoral student in civil and environmental engineering at U-M, encountered an article indicating that woven baskets date back to approximately 7500 BCE, the researchers began to question whether this ancient skill remains relevant today for reasons that extend beyond geometry and aesthetics.

“We realized that weaving is a successful method for constructing 3D shapes from strips such as reeds and barks, but we suspected there were also fundamental mechanical benefits,” stated Evgueni Filipov, an associate professor of civil and environmental engineering and mechanical engineering at U-M and the study’s corresponding author.

The research, backed by the U.S. Air Force Office of Scientific Research, uncovered the mechanical advantages: high stiffness suitable for load-bearing tasks and durability for extended use.

“I am quite thrilled to leverage the advantages of ancient basket weaving for contemporary engineering applications in the 21st century,” Filipov expressed. “For example, lightweight woven materials for robotics would enhance human safety in the event of collisions between humans and robots.”

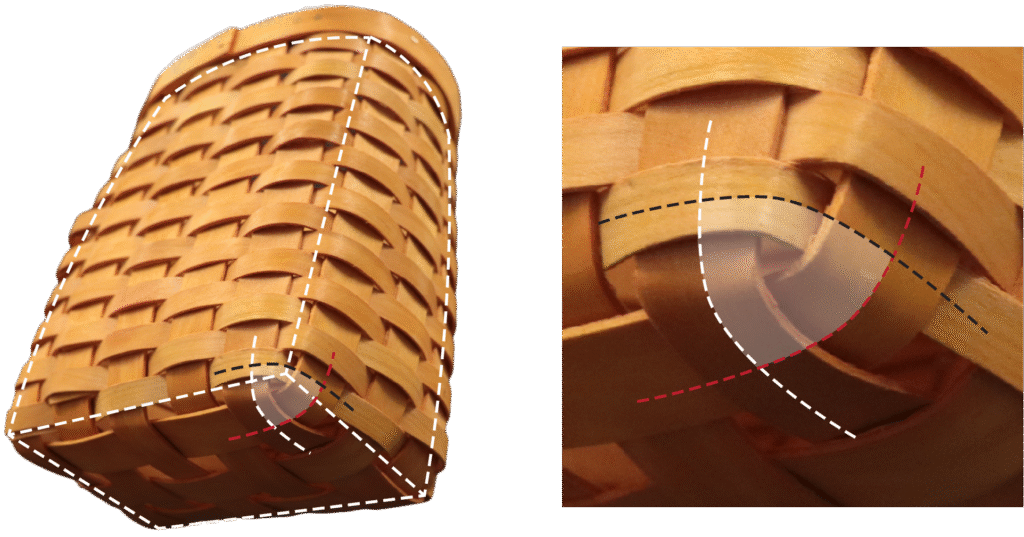

To evaluate mechanical characteristics, the research team constructed structures by weaving Mylar polyester ribbons, akin in width to a pinky finger and the thickness of two sheets of paper, arranged orthogonally. They transformed this 2D weave into a 3D metamaterial—indicating a synthetic composite material with a structure that manifests physical properties absent in natural materials.

“While modern metamaterials are frequently designed for electromagnetic, optical, or acoustic properties, humans have been creating mechanical metamaterials through weaving and other structural methods for millennia,” Tu noted.

The structures utilized four distinct corner configurations joining three, four, five, and six planes. For comparison, the team created equivalent structures with continuous, unwoven Mylar. They subsequently tested both variations through progressive compression.

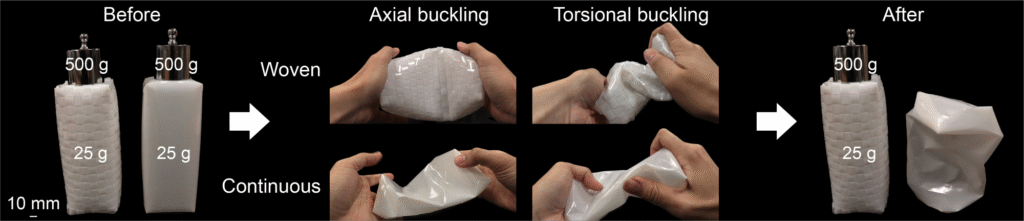

A pair of rectangular boxes measuring 17 centimeters in height returned to their initial shape after being compressed by one centimeter. When subjected to additional compression, the continuous structure suffered permanent damage while the woven version remained intact, even after being compressed by 14 centimeters, reducing to less than 20% of its initial height.

High-resolution 3D scans identified locations on the continuous structure where concentrated stress led to buckling and deformation. The woven structure, conversely, redistributes the stress over a broader area, safeguarding it against permanent harm.

Subsequently, the research team explored stiffness, gauged by the force necessary to compress structures from the top or bend them laterally. They tested all four corner configurations against continuous structures of the same Mylar polyester. In every experiment, woven materials proved to be 70% as stiff as their continuous alternatives—contradicting the belief that woven systems are inherently flexible.

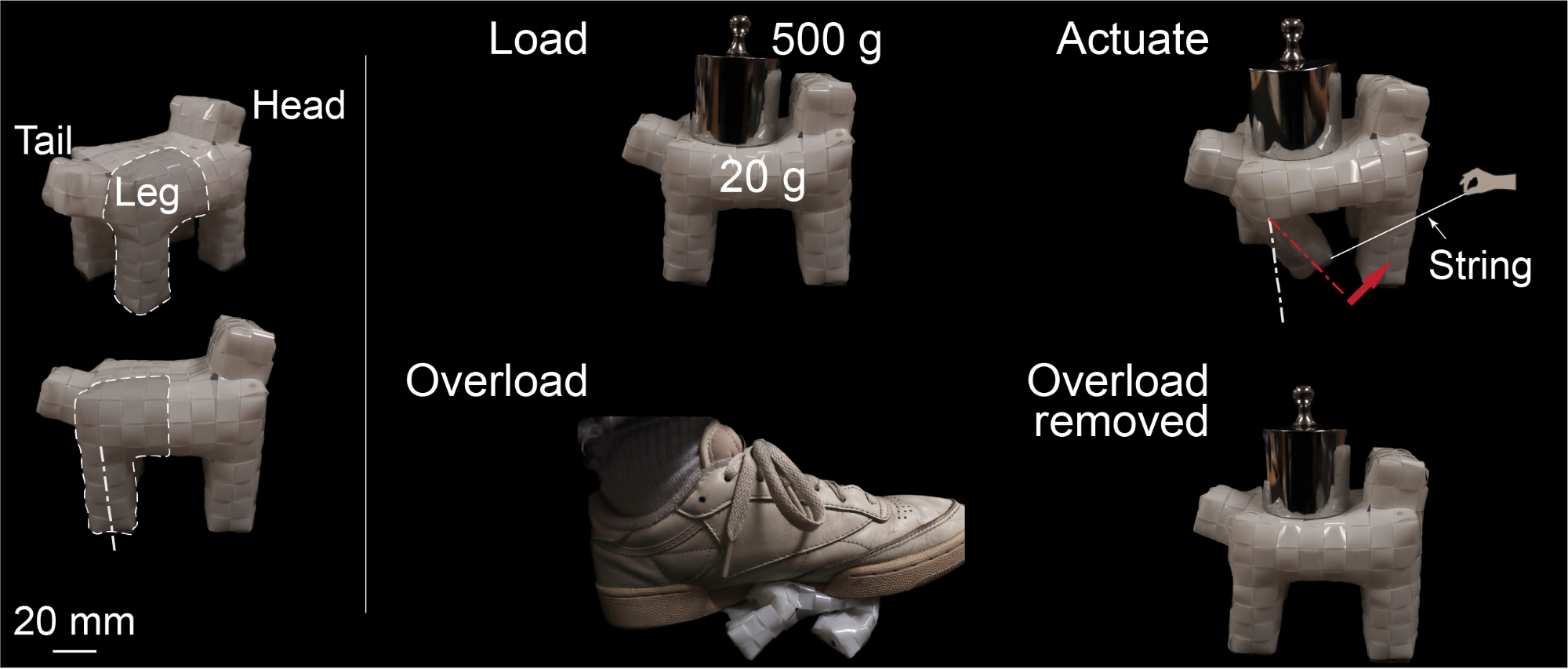

Upon testing more intricate designs, an L-shaped structure resembling a robotic arm supported 80 times its weight in a vertical position—similar to holding a heavy bag at waist level—and easily flexed upward, mimicking human arm movement. A prototype of a woven robot with four legs, referred to by the researchers as a dog, could support 25 times its weight while still moving its legs to walk. Once overloaded, the woven dog robot reverted to its original shape, capable of sustaining the same weight once again.

“Utilizing these fundamental corner-shaped modules, we can devise and easily produce woven surfaces and structural systems with intricate spatial geometries that are both rigid and resilient,” Tu remarked. “The potential applications for these corner-based woven structures in future engineering design are immense.”

As an example of potential application, the researchers have conceived of a woven exoskeleton that adjusts its stiffness according to different regions of the human body—enabling movement while providing reusable shock absorption.

“Moving ahead, our goal is to incorporate active electronic materials into these woven constructs so they can evolve into ‘smart’ systems capable of sensing the external environment and adapting their shapes in response to various application scenarios,” Filipov concluded.

The research received partial funding from the U.S. Air Force Office of Scientific Research (FA9550-22-1-0321).

“`