“`html

Collaborating with robots is becoming increasingly prevalent in the recycling sector, facilitating automation of tasks and simplifying complex work. However, educating human workers to operate alongside robots can be challenging and time-intensive.

Scholars from the University of Georgia have developed a new virtual reality environment to accelerate and simplify training.

One procedure that frequently needs robotic assistance is disassembly. It is essential for recycling components and precious materials from electronics that are approaching the end of their usability. Yet, disassembly tasks often come with their own set of difficulties.

“In contrast to assembly, which follows a very standardized protocol, disassembly is a bit more intricate,” remarked Beiwen Li, lead author of the research and an associate professor at UGA’s College of Engineering. “Simply reversing the entire assembly process may not yield the best results.”

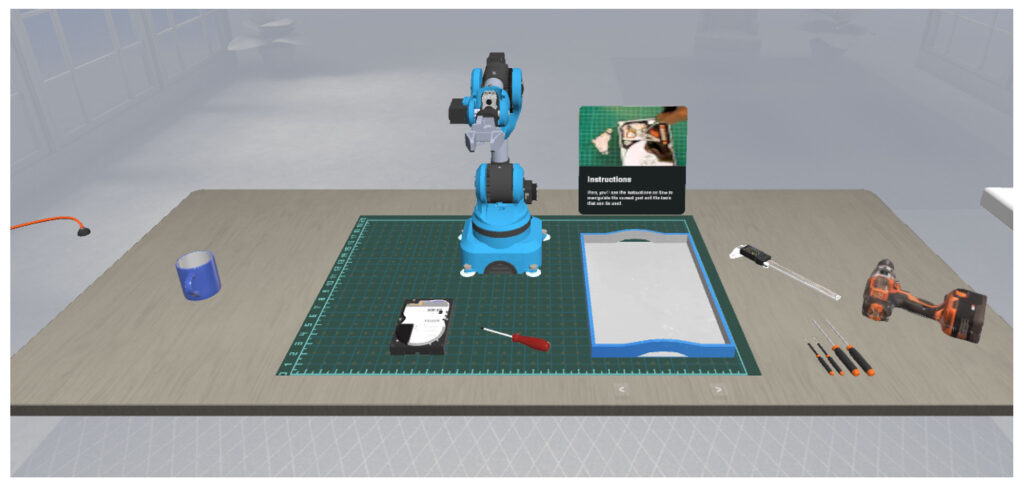

The researchers designed VR Co-Lab to alleviate confusion. By training staff in a digital format, they can practice disassembling recyclable items without compromising materials, while also learning to prevent injuries and collisions with the robot.

Utilizing virtual reality to reduce training duration

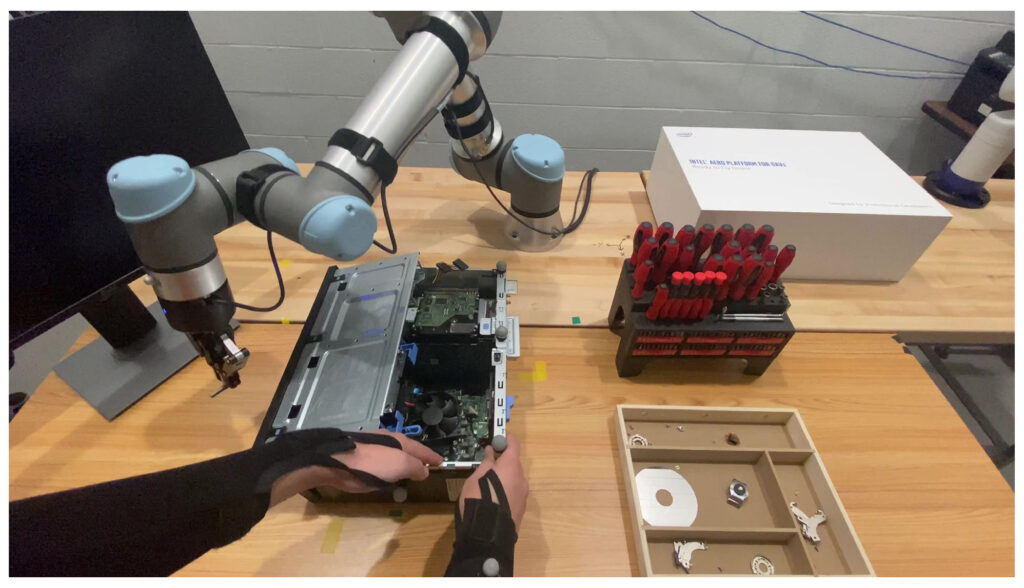

Within the virtual setting, participants practiced disassembling a hard drive with assistance from a robot.

Upon donning their headsets, they found themselves in a virtual workspace resembling that of their actual job. They encountered various tools and machinery necessary for disassembly, along with the robot providing support.

During the training sessions, workers adhered to a systematic procedure for dismantling the hard disk. Human participants performed more detailed operations, such as unscrewing or manipulating small bolts, while the robotic arm handled larger bolts and loose components. The program also offered feedback to users, tracking how long the session took and the number of errors made.

“There are numerous tasks involved. It typically demands extensive training for workers,” Li noted. “Thus, implementing a VR system would be incredibly beneficial in reducing training duration. It is far simpler than having users sift through pages and pages of written documentation.”

Enhancing performance while ensuring worker safety

A significant component of the VR system is body tracking.

VR Co-Lab utilizes Meta Quest Pro, which employs its cameras to monitor upper body movements, including wrists, elbows, shoulders, and torso. This allows the program to coordinate the robot’s movements based on user actions, reducing the chances of collisions and enhancing interaction between human and machine.

The program alerts users to possible hazards that may result in injury, such as clashes with the robotic arm, while instructing them on how to circumvent such issues. Additionally, the system can assess how swiftly the robotic arm operates without overwhelming the worker.

Robots will play a vital role in the future of the recycling sector.” — Beiwen Li, College of Engineering

Li and his research team plan to conduct more extensive user testing in the future to ensure the system is beneficial for various skill levels and adaptable for tasks beyond disassembling hard drives. Enhancing the training process will be crucial as robotic utilization becomes more widespread.

“Robots will be essential for the future of the recycling industry because they can automate numerous disassembly steps. This can help alleviate the labor shortage,” Li stated. “Given the complexity of disassembly, it requires human collaboration with robots. That remains our motivation for creating this VR system for training.”

The study was published in Machines and financed by a grant from the National Science Foundation. It was jointly authored by Yashwanth Maddipatla from Iowa State University, along with Sibo Tian, Xiao Liang, and Minghui Zheng from Texas A&M University.

The post VR could assist in training employees working with robots appeared first on UGA Today.

“`