“`html

Diffusion models, such as OpenAI’s DALL-E, are proving to be increasingly beneficial in assisting with the ideation of novel designs. Individuals can instruct these systems to produce an image, develop a video, or enhance a blueprint, returning with concepts they had not previously contemplated.

However, were you aware that generative artificial intelligence (GenAI) models are also advancing in the creation of functional robots? Recent diffusion-based techniques have produced structures and the systems governing them entirely from scratch. With or without user intervention, these models can generate fresh designs and subsequently assess them through simulation prior to their production.

A novel method from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) leverages this generative expertise to enhance human robotic designs. Users can create a 3D model of a robot and specify which components they wish for a diffusion model to adjust, providing measurements in advance. GenAI then conceptualizes the most effective shape for these sections and validates its concepts in simulation. When the system identifies the optimal design, it can be saved and then produced as a functional, real-world robot using a 3D printer, without needing further modifications.

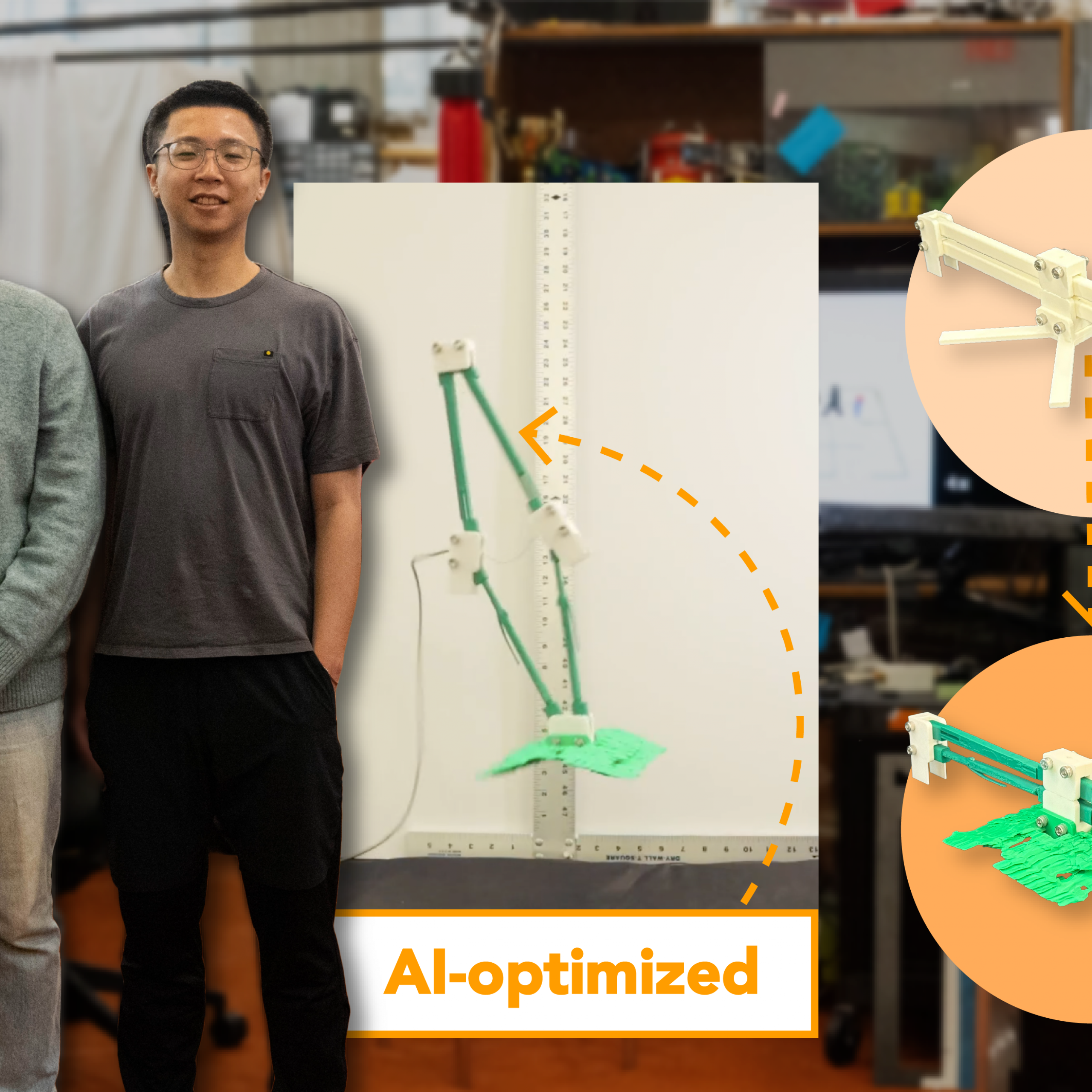

The researchers utilized this method to construct a robot that can jump an average of approximately 2 feet, which is about 41 percent higher than a similar device they designed independently. The machines are nearly indistinguishable in appearance: both are crafted from a type of plastic known as polylactic acid, and although they initially seem flat, they spring into a diamond shape when a motor pulls on the cord connected to them. So, what exactly did the AI approach differently?

A detailed examination indicates that the AI-created linkages are curved and resemble thick drumsticks (the instrument used by drummers), while the conventional robot’s connecting components are straight and rectangular.

Improving and enhancing shapes

The researchers commenced refining their jumping robot by sampling 500 potential designs utilizing an initial embedding vector—a numerical representation that encapsulates high-level features to steer the designs created by the AI model. From these options, they selected the top 12 based on performance in simulation and employed them to optimize the embedding vector.

This sequence was repeated five times, gradually directing the AI model to produce superior designs. The resulting creation resembled a blob, leading the researchers to prompt their system to adjust the draft to correspond to their 3D model. Upon fabricating the shape, they discovered it indeed enhanced the robot’s jumping performance.

The benefit of deploying diffusion models for this task, according to co-lead author and CSAIL postdoc Byungchul Kim, is their capacity to uncover unconventional refinements for robots.

“We aimed to elevate our machine’s jump height, so we thought making the links connecting its parts as thin as possible to reduce weight would be effective,” explains Kim. “However, such a slender structure can easily fracture if constructed solely from 3D printed material. Our diffusion model proposed a more optimal design by suggesting a unique shape that permitted the robot to accumulate more energy before jumping, without compromising the thickness of the links. This ingenuity helped us gain insights into the underlying physics of the machine.”

The team then tasked their system with drafting an optimized foot to ensure stable landings. They repeated the optimization process, ultimately selecting the highest-performing design to attach to the base of their device. Kim and his colleagues observed that their AI-engineered machine fell significantly less often than its baseline, resulting in an 84 percent improvement.

The diffusion model’s proficiency in enhancing a robot’s jumping and landing capabilities suggests potential applicability in refining designs for other machines. For instance, firms focused on manufacturing or household robots could employ a similar methodology to enhance their prototypes, conserving engineers’ time typically spent on iterative changes.

The equilibrium behind the leap

To engineer a robot capable of high jumps and stable landings, the researchers recognized the need to achieve a balance between both objectives. They quantified both jump height and landing success rate as numerical data, subsequently training their system to identify an optimal balance between both embedding vectors to facilitate the construction of an optimal 3D structure.

The researchers observe that, while this AI-assisted robot surpassed its human-designed equivalent, it holds the potential to reach even greater heights. This iteration utilized materials compatible with 3D printing; however, future iterations may achieve even higher jumps with lighter materials.

Co-lead author and MIT CSAIL PhD student Tsun-Hsuan “Johnson” Wang conveys that this project serves as a foundational step for new robotic designs that generative AI could aid with.

“We aspire to expand towards more versatile goals,” states Wang. “Imagine utilizing natural language to direct a diffusion model for drafting a robot capable of lifting a mug or operating an electric drill.”

Kim adds that a diffusion model could also assist in generating articulations and conceptualizing how components connect, potentially boosting the robot’s jumping height. The team is also investigating the possibility of incorporating additional motors to control the direction of the robot’s jumps and potentially enhance its landing stability.

The researchers’ efforts received partial support from the National Science Foundation’s Emerging Frontiers in Research and Innovation program, the Singapore-MIT Alliance for Research and Technology’s Mens, Manus and Machina program, and the Gwangju Institute of Science and Technology (GIST)-CSAIL Collaboration. They presented their findings at the 2025 International Conference on Robotics and Automation.

“`