“`html

For years, it has been recognized that subtle chemical arrangements exist in metal alloys, yet researchers believed they were too insignificant to be relevant — or that they vanished during fabrication. Nevertheless, recent investigations have demonstrated that in controlled environments, these arrangements can alter a metal’s characteristics, including its mechanical strength, resilience, thermal capacity, radiation resistance, and more.

Currently, scholars at MIT have discovered that these chemical arrangements also occur in traditionally produced metals. This unexpected revelation unveiled a new physical phenomenon that clarifies the enduring patterns.

In a paper published in Nature Communications today, the researchers elaborate on how they monitored the patterns and uncovered the physics that accounts for them. The authors also devised a straightforward model to anticipate chemical arrangements in metals and demonstrated how engineers could utilize the model to adjust the impact of such patterns on metallic characteristics, applicable in aerospace, semiconductors, nuclear reactors, and beyond.

“The takeaway is: You can never entirely randomize the atoms in a metal. The processing method doesn’t change that,” Freitas explains. “This is the first document revealing these non-equilibrium states that persist within the metal. At present, this chemical order is not something we’re managing or observing during metal fabrication.”

For Freitas, an early-career investigator, the results validate his decision to explore a congested field that he claims few expected would yield unique or widely significant outcomes. He acknowledges the U.S. Air Force Office of Scientific Research, which funded the project through their Young Investigator Program. He also appreciates the collaborative effort that made the paper possible, featuring three MIT PhD students as co-first authors: Mahmudul Islam, Yifan Cao, and Killian Sheriff.

“There was a dilemma about whether I should even attempt to tackle this particular problem since it has been under investigation for quite some time,” Freitas notes. “However, the more I delved into it, the more I realized researchers were considering this in idealized lab scenarios. We aimed to execute simulations that mirrored these manufacturing processes with high precision. My favorite aspect of this project is how counterintuitive the findings are. The idea that something cannot be entirely mixed caught people off guard.”

From surprises to theories

Freitas’ research group started with a practical inquiry: How rapidly do chemical elements combine during metal processing? Conventional knowledge suggested that there’s a threshold where the chemical composition of metals achieves complete uniformity through mixing during fabrication. By identifying that threshold, the researchers believed they could create a straightforward method for designing alloys with varying degrees of atomic order, also known as short-range order.

The researchers employed machine-learning approaches to track millions of atoms as they shifted and rearranged under conditions simulating metal processing.

“The first step we took was to deform a piece of metal,” Freitas clarifies. “That’s a typical procedure during manufacturing: You roll the metal, deform it, heat it again, and deform it slightly more to develop the desired structure. We executed that and monitored the chemical order. The assumption was that as you deform the material, its chemical bonds break, randomizing the system. These intense manufacturing methods essentially shuffle the atoms.”

The researchers encountered an obstacle during the mixing process: The alloys never attained a completely random state. This was unexpected, as no known physical mechanism could elucidate the result.

“It indicated a new aspect of physics in metals,” the researchers state in the paper. “It was one of those instances where applied research led to a fundamental discovery.”

To uncover the new physics, the researchers created computational tools, including high-fidelity machine-learning models, to capture atomic interactions, along with new statistical techniques to quantify how chemical order evolves over time. They then deployed these tools in extensive molecular dynamics simulations to monitor how atoms rearrange during processing.

The researchers identified certain standard chemical formations in their processed metals, but at temperatures higher than typically anticipated. Even more astonishingly, they discovered entirely new chemical patterns previously unseen outside of manufacturing processes. This was the first occasion these patterns were detected. They referred to the patterns as “far-from-equilibrium states.”

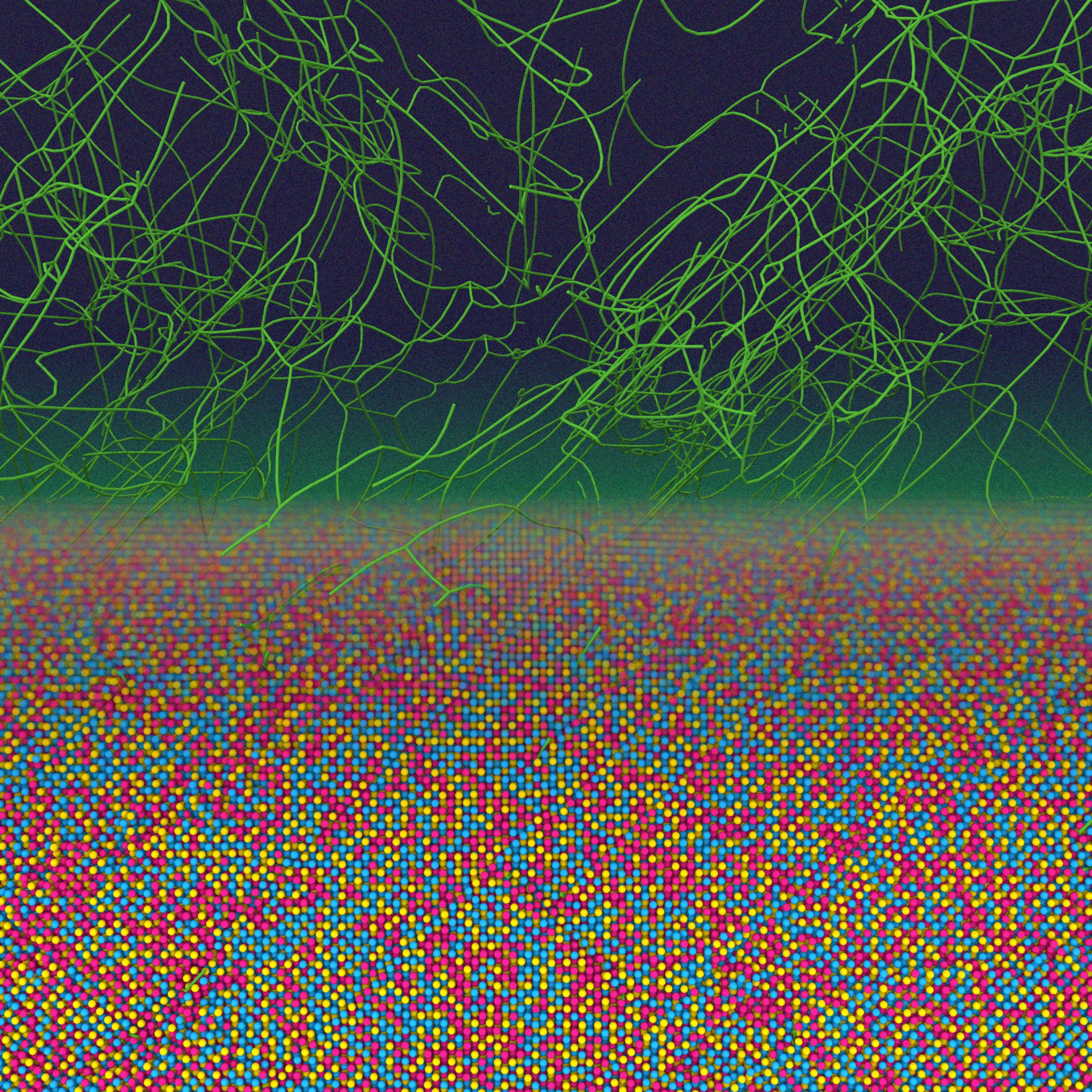

Furthermore, the researchers constructed a simple model that replicated key features of the simulations. The model elucidates how the chemical patterns arise from defects known as dislocations, which resemble three-dimensional scribbles within a metal. As the metal deforms, these scribbles distort, shuffling nearby atoms in the process. Previously, researchers thought that shuffling completely obliterated order in the metals, but they found that dislocations favor specific atomic exchanges over others, resulting in subtle patterns rather than randomness, explaining their discoveries.

“These defects possess chemical preferences guiding their movement,” Freitas comments. “They seek low-energy paths, so when given the option to break chemical bonds, they tend to break the weakest ones, and it’s not entirely random. This is quite fascinating because it illustrates a non-equilibrium state: It’s not a behavior you would see naturally occurring in materials. It parallels how our bodies exist in non-equilibrium. The external temperature is always either hotter or colder than our bodies, and we strive to maintain a steady state equilibrium to survive. That’s the reason these states manifest in metals: the balance between an internal urge for disorder and the tendency to break certain bonds that are weaker.”

Applying a new theory

Researchers are currently investigating how these chemical patterns emerge across diverse manufacturing scenarios. The outcome is a framework that associates various metal processing stages with distinct chemical patterns in metal.

Thus far, this chemical order and the properties it influences have largely been viewed as an academic topic. With this framework, the researchers aspire for engineers to perceive these patterns as design levers that can be manipulated during production to achieve novel properties.

Researchers have already conveyed to Freitas that the paper could elucidate other unexpected findings about metallic properties, and he is eager for the field to transition from fundamental research on chemical order to more applied endeavors.

“You can envision areas where optimized alloys are crucial, such as aerospace,” Freitas suggests. “They focus on very specific compositions. Advanced manufacturing now enables the combination of metals that typically wouldn’t mix through deformation. Understanding how atoms actually shuffle and mix in those processes is essential, because it’s critical for enhancing strength while maintaining low density. Therefore, this could be a significant advancement for them.”

This research was supported, in part, by the U.S. Air Force Office of Scientific Research, MathWorks, and the MIT-Portugal Program.

“`