“`html

Available to industry and academic investigators, the lab will assist in advancing more battery technology to the marketplace

In a move aimed at sustaining U.S. research and innovation momentum in advanced battery technology for electric vehicles and beyond, the University of Michigan has augmented its open-access U-M Battery Lab with a second off-campus site.

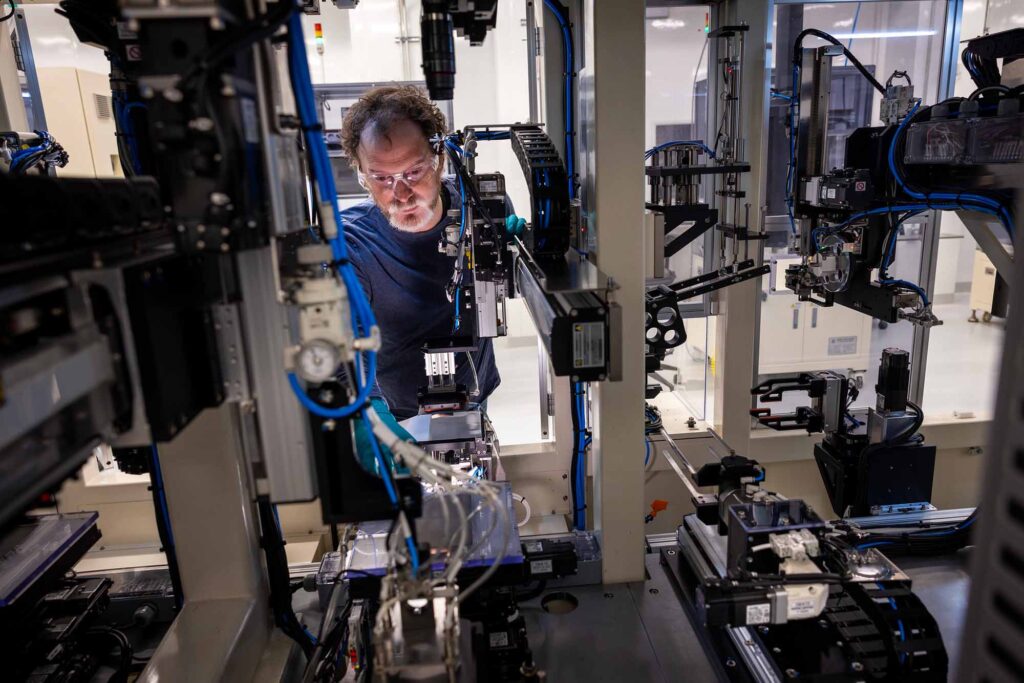

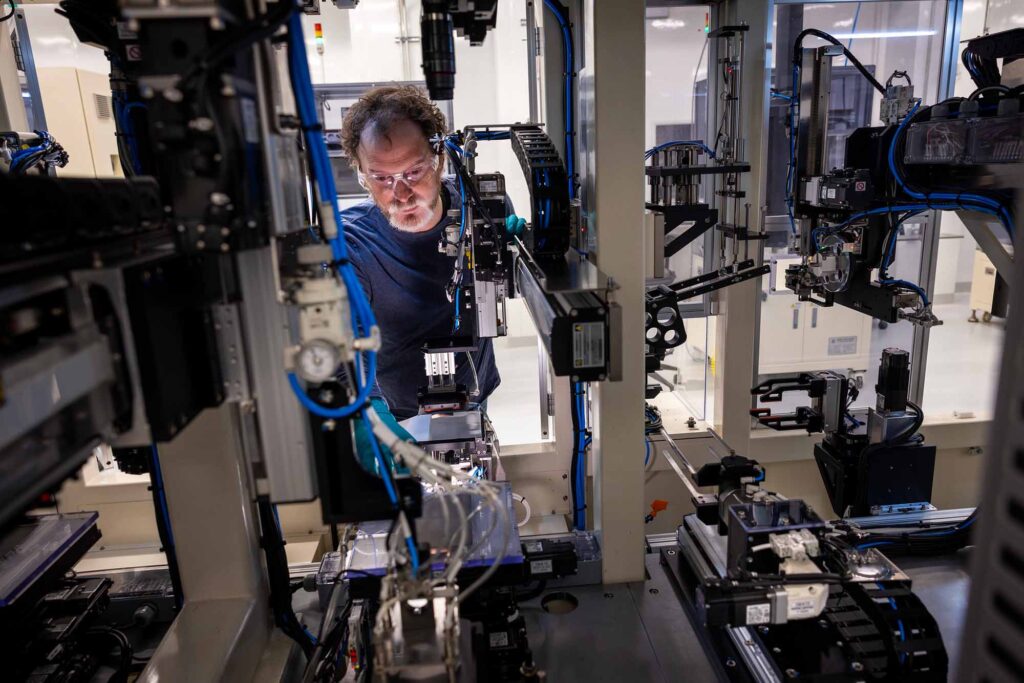

Accessible to both academic and industry researchers, Battery Lab 2.0 introduces an additional 4,000 square feet of laboratory and production space on Ellsworth Road in Ann Arbor. Its machinery lineup features an industry-standard automated laser welder for the assembly of battery modules and packs. Moreover, its three-megawatt-hour lithium-ion battery production line is thought to be the highest-capacity pilot-scale line situated at a university.

“In the ten years since the initial U-M Battery Lab was established—the first of its kind in the nation and currently the only one situated in the heart of the automotive sector—it has been a crucial enabler. It has stimulated many of the battery innovations now driving today’s EVs,” stated Alan Taub, director of the U-M Electric Vehicle Center and professor of materials science and mechanical engineering.

“However, demand has persistently exceeded capacity, which is why we’ve broadened our reach—providing researchers with even more space to construct the future.”

The lab’s functions encompass prototyping, testing, and manufacturing a variety of lithium-ion, solid-state, and next-generation rechargeable batteries in both pouch and cylindrical forms. These prevalent formats have applications in grid storage, personal devices, standby generators, drones, and defense technologies, in addition to EVs.

Makerspaces like U-M’s Battery Lab create avenues for companies lacking in-house laboratories or manufacturing setups to experiment with ideas, customize prototypes, and produce products. Users of the lab have included established companies like Ford, Mercedes-Benz, and PPG Industries, as well as startups like MIT-spinout Nanoramic.

“We connect the ‘valley of death’—the time frame between a promising idea or early-stage technology and its commercial production. We offer the infrastructure, equipment, and expertise necessary to validate that you possess a viable product,” explained Greg Less, the battery lab director.

“We’ve assisted major automakers, while also providing smaller enterprises a place at the table. The more new concepts emerge, the quicker technology progresses. What we provide them is as near to industrial prototyping as one can achieve.”

Nanoramic characterizes the lab as “essential in promoting their R&D initiatives.” Late last year, the company secured $44 million in a financing round co-led by GM Ventures, with Samsung Ventures participating.

The original Battery Lab was inaugurated on U-M’s North Campus in 2014. Almost immediately, and since then, the $9 million facility has been completely booked by scholars and industrial researchers from around the world. Its location enables accessibility to a range of industries.

“Being located near the automotive sector is mutually beneficial,” Less remarked. “They do not have to increase their internal capabilities since they can utilize what we offer. And when they visit our campus, we gain valuable insights from them.”

The lab expansion, based on Ellsworth Road, includes:

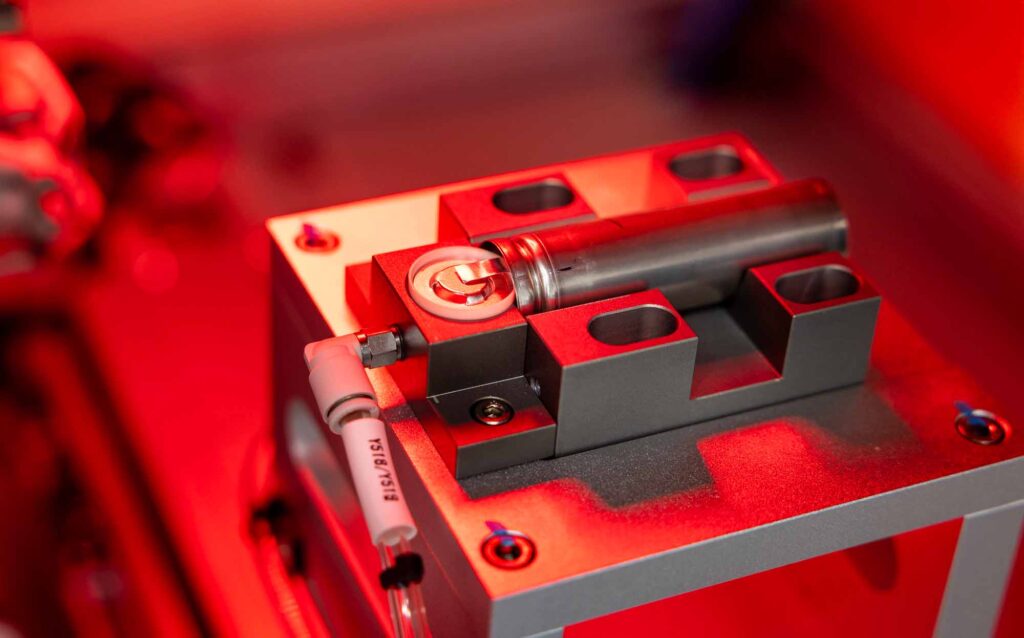

- A 4,000-square-foot dry room where humidity can be accurately managed, enabling researchers to combine and coat highly delicate, next-generation materials.

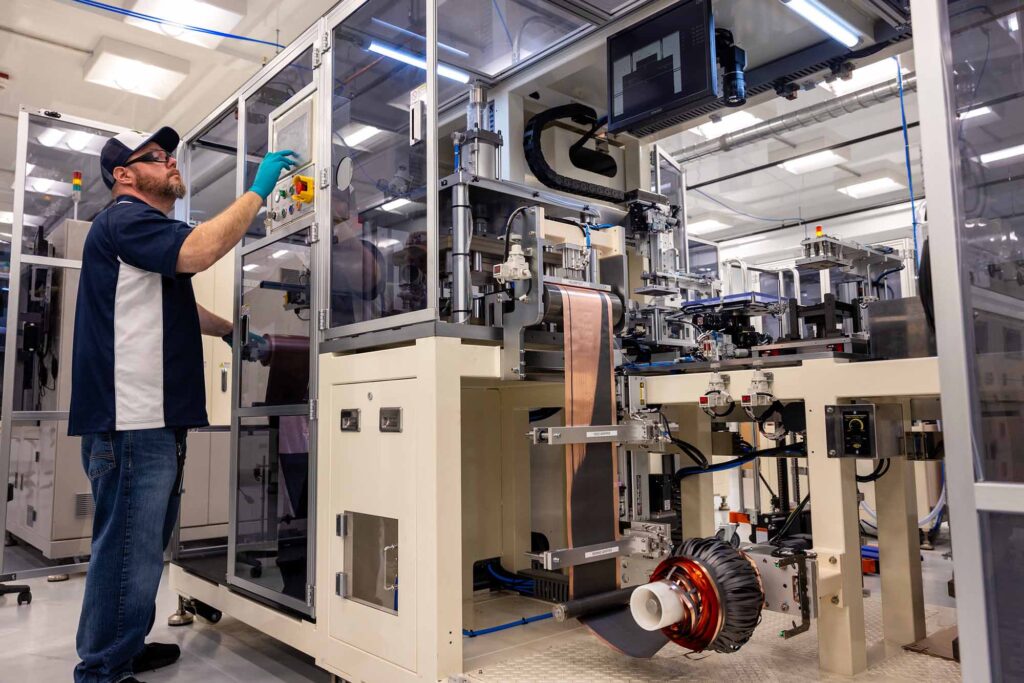

- An increased maximum mixing volume of 30 liters, up from 10 liters at the original battery lab, facilitating the production of larger and more numerous batteries.

- A lengthened coating system of 6 meters, allowing for quicker application and enhanced control over the drying process of the electrode material during cell fabrication.

- Capability to produce both the 21700 format cylindrical batteries and the 100×150-millimeter format pouch batteries. These larger cell formats are more indicative of contemporary automotive cells.

- An automated laser welder for integrating cells into larger groups, referred to as modules and, ultimately, battery packs—just as they would be deployed in the market.

Battery Lab 2.0 serves as an interim solution during the design and development of a $60 million on-campus battery lab that will be an addition to the U-M Transportation Research Institute building. Funding for this expansion as well as the future on-campus lab is derived from the state of Michigan’s $130 million contract that established the Electric Vehicle Center in 2023.

Battery Lab 2.0 is situated off U-M’s campus, near the southern boundary of Ann Arbor, thus allowing industrial users more convenient access. The new equipment was produced by Energy Tech Solution.

“`