Graphite serves as a crucial structural element in some of the planet’s oldest nuclear reactors as well as in many modern designs currently under construction. However, it also contracts and expands in response to radiation — and the underlying processes for these variations have been challenging to investigate.

Recently, researchers at MIT and their partners have identified a connection between the characteristics of graphite and its behavior when exposed to radiation. These discoveries may facilitate more precise and less invasive methods for forecasting the durability of graphite materials utilized in reactors globally.

“We conducted fundamental research to comprehend the factors that lead to expansion and, ultimately, failure in graphite structures,” states MIT Research Scientist Boris Khaykovich, the senior author of the latest study. “Further investigations are necessary to apply this practically, but the paper suggests a compelling concept for the industry: that it might not be essential to destroy hundreds of irradiated samples to ascertain their failure points.”

In particular, the research reveals a correlation between the size of the pores within graphite and how the material expands and contracts in volume, contributing to deterioration.

“The lifespan of nuclear graphite is constrained by swelling caused by irradiation,” notes co-author and MIT Research Scientist Lance Snead. “Porosity acts as a crucial factor in this swelling, and while graphite has been extensively examined for nuclear purposes since the Manhattan Project, our understanding of porosity concerning mechanical properties and swelling is still unclear. This study addresses that gap.”

The open-access paper is published this week in Interdisciplinary Materials. It is co-authored by Khaykovich, Snead, MIT Research Scientist Sean Fayfar, former MIT research fellow Durgesh Rai, Stony Brook University Assistant Professor David Sprouster, Oak Ridge National Laboratory Staff Scientist Anne Campbell, and Argonne National Laboratory Physicist Jan Ilavsky.

An extensively researched, intricate material

Since 1942, when physicists and engineers constructed the world’s inaugural nuclear reactor in a repurposed squash court at the University of Chicago, graphite has been instrumental in nuclear energy generation. This original reactor, called the Chicago Pile, consisted of around 40,000 graphite blocks, many incorporating uranium nuggets.

Today, graphite is an essential element in numerous operational nuclear reactors and is anticipated to be pivotal in next-generation reactor designs such as molten-salt and high-temperature gas reactors. Graphite is effective as a neutron moderator, slowing down neutrons released through nuclear fission, making them more likely to initiate additional fissions and maintain a chain reaction.

“The straightforwardness of graphite is what makes it valuable,” Khaykovich elaborates. “It’s composed of carbon, and we have a relatively well-established method for producing it in a clean manner. Graphite is a well-established technology. It’s uncomplicated, reliable, and we understand it works.”

Nevertheless, graphite possesses its complexities.

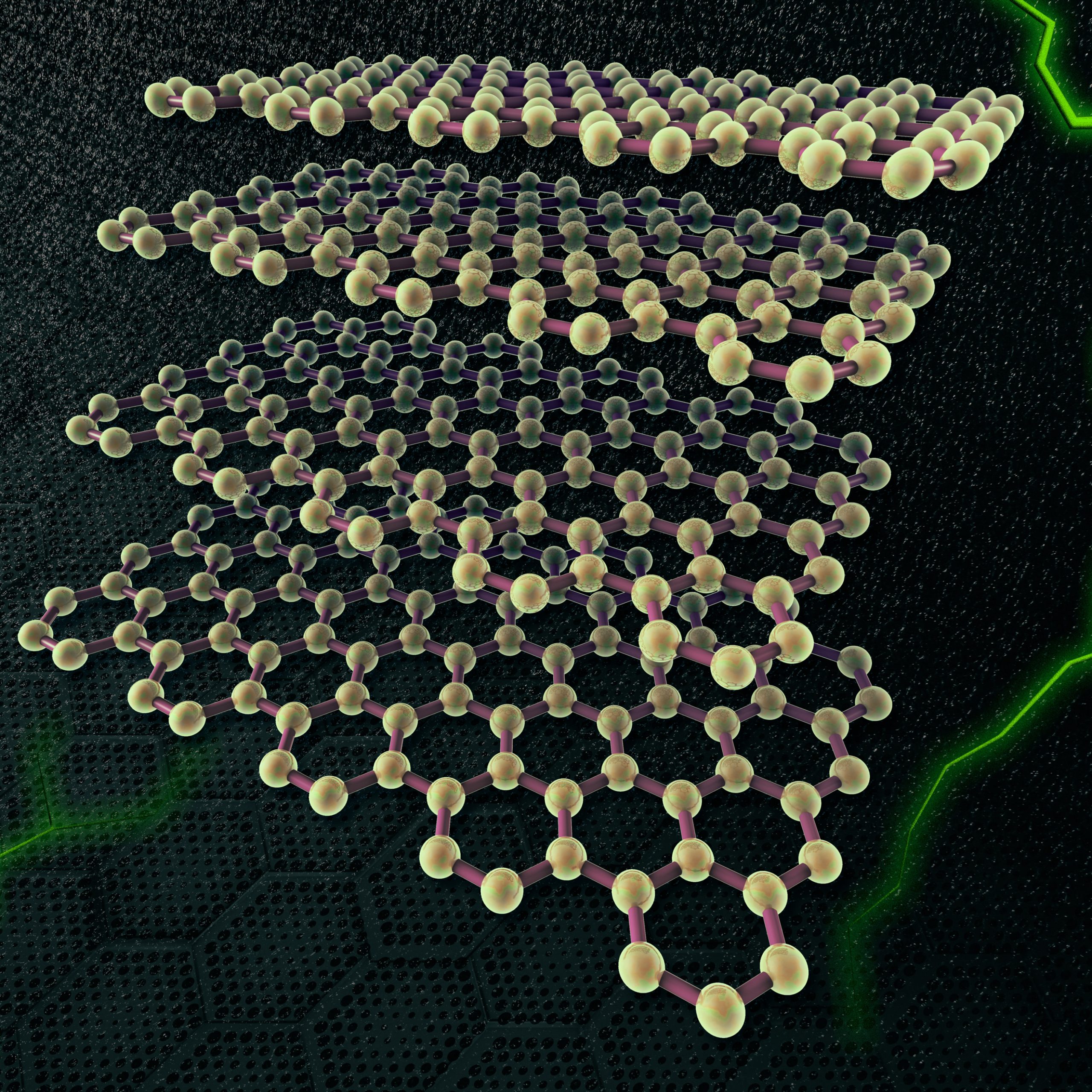

“We refer to graphite as a composite even though it consists solely of carbon atoms,” Khaykovich remarks. “It contains ‘filler particles’ that are more crystalline, while a matrix known as a ‘binder’ is less crystalline, and there are pores that range from nanometers to several microns in length.”

Each grade of graphite has a distinct composite structure, but all feature fractals, or shapes that appear similar at varying scales.

These intricacies have made it challenging to forecast how graphite will respond to radiation on a microscopic level, although it has been recognized for decades that when irradiated, graphite initially densifies, reducing its volume by up to 10 percent, before swelling and fracturing. The volume variation is driven by modifications to graphite’s porosity and lattice stress.

“Graphite deteriorates under radiation, as does any material,” Khaykovich states. “So, on one hand, we have a material that’s extraordinarily well-understood, and on the other, a material that is immensely complex, with behavior that defies prediction via computer simulations.”

For this study, researchers acquired irradiated graphite samples from Oak Ridge National Laboratory. Co-authors Campbell and Snead were involved in irradiating these samples approximately 20 years ago. The samples belong to a graphite grade identified as G347A.

The research team employed an analytical method known as X-ray scattering, which analyzes material properties based on the scattered intensity of an X-ray beam. Specifically, they examined the distribution of sizes and surface areas of the pores within the samples, or their fractal dimensions.

“When examining the scattering intensity, quite a range of porosity is apparent,” Fayfar explains. “Graphite exhibits porosity across such extensive scales, and there’s this fractal self-similarity: The pores in minute sizes resemble those spanning microns, prompting us to use fractal models to link different morphologies across various length scales.”

Fractal models have previously been employed on graphite samples, but not on irradiated ones to observe changes in the material’s pore structures. The researchers discovered that upon initial exposure to radiation, graphite’s pores become filled as the material begins to degrade.

“What surprised us was that the [size distribution of the pores] eventually reversed,” Fayfar mentions. “We observed a recovery process that correlated with our overall volume trends, which was intriguing. It appears that after prolonged irradiation, graphite begins to recover. It resembles an annealing process where new pores form, and then the existing pores smooth out and slightly enlarge. That was quite unexpected.”

The researchers noted that the size distribution of the pores closely aligns with the volume changes triggered by radiation damage.

“Identifying a strong relationship between the [size distribution of pores] and the volume alterations in graphite is a new revelation, assisting in connecting to the material’s failure under irradiation,” Khaykovich asserts. “It’s crucial for individuals to comprehend how graphite components will fail under stress and how the failure likelihood shifts under irradiation.”

From research to reactors

The team intends to investigate additional graphite grades and delve deeper into how pore sizes in irradiated graphite relate to the probability of failure. They propose that a statistical approach known as the Weibull Distribution might be applied to predict the lifespan of graphite until it fails. The Weibull Distribution is currently utilized to describe failure probabilities in ceramics and various porous materials like metal alloys.

Khaykovich also conjectured that these findings might enhance our understanding of why materials densify and expand when exposed to irradiation.

“No quantitative model of densification currently accounts for what occurs at these tiny scales in graphite,” Khaykovich states. “The densification of graphite under irradiation reminds me of sand or sugar; when larger pieces are crushed into smaller grains, they densify. For nuclear graphite, the crushing force is the energy introduced by neutrons, filling larger pores with smaller, fragmented pieces. However, increased energy and agitation lead to the formation of even more pores, causing graphite to swell again. It’s not a perfect comparison, but I believe analogies contribute to progress in understanding these materials.”

The researchers consider the paper an essential advancement toward enhancing graphite production and application in future nuclear reactors.

“Graphite has been scrutinized for a considerable time, and we’ve built strong insights regarding its responses in various environments, but when constructing a nuclear reactor, intricacies matter,” Khaykovich comments. “Stakeholders demand precise data. They need clarity on thermal conductivity variations, anticipated cracking and volume changes. If components are altering size, this must be factored in at some point.”

This research received partial funding from the U.S. Department of Energy.