“`html

If your hand cream is somewhat more liquid than typical while exiting the container, it could be related to the substance’s “mechanical memory.”

Soft gels and creams are produced by combining components until they achieve a consistent and stable mixture. Yet, even after a gel has solidified, it can retain “memories,” or leftover stress, from the blending process. Gradually, the substance may succumb to these embedded stresses and revert to its previous, unblended state. Mechanical memory is, in part, the reason hand cream separates and becomes liquid over time.

Recently, a MIT engineer has created a straightforward method to gauge the level of residual stress in soft substances post-mixing, discovering that everyday items like hair gel and shaving cream possess extended mechanical memories, retaining residual stresses longer than manufacturers might have expected.

In a study published today in Physical Review Letters, Crystal Owens, a postdoctoral researcher at MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL), introduces a new method for assessing residual stress in soft, gel-like substances, utilizing a standard benchtop rheometer.

When applying this method to common soft materials, Owens discovered that if a gel is created by mixing it in a specific direction, once it stabilizes into a uniform and steady state, it effectively retains the memory of the direction in which it was combined. Even after several days, the gel maintains some internal stress which, if released, will cause it to shift in the opposite direction to how it was originally mixed, returning to its former state.

“This is one reason why various batches of cosmetics or food can act differently even if they went through ‘identical’ manufacturing,” Owens explains. “Grasping and measuring these hidden stresses during production could aid manufacturers in crafting superior products that endure longer and function more reliably.”

A soft glass

Hand cream, hair gel, and shaving foam all belong to the category of “soft glassy materials” — substances that demonstrate characteristics of both solids and liquids.

“Anything you can pour into your hand that forms a gentle mound can be classified as a soft glass,” Owens clarifies. “In materials science, it is regarded as a softer version of something that shares the same amorphous structure as glass.”

In essence, a soft glassy material is an unusual blend of solid and liquid. It can be poured out like a fluid, and it can maintain its shape like a solid. Once created, these materials coexist in a fragile equilibrium between solid and liquid. And Owens pondered: For how long?

“What occurs with these materials over very extensive periods? Do they eventually relax, or do they remain in their current state indefinitely?” Owens asks. “From a physics standpoint, that’s a fascinating question: What is the fundamental condition of these materials?”

Twist and hold

During the production of soft glassy materials such as hair gel and shampoo, components are initially blended into a consistent product. Quality assurance specialists then allow a sample to sit for around a minute — a timeframe they believe is sufficient for any residual stresses from the mixing phase to dissipate. During this period, the material should settle into a steady, stable state, prepared for usage.

However, Owens speculated that the materials might retain a certain level of stress from the manufacturing process long after they seem to have settled.

“Residual stress is a low level of stress trapped within a material after it reaches a steady state,” Owens remarks. “This type of stress hasn’t been quantified in these kinds of materials.”

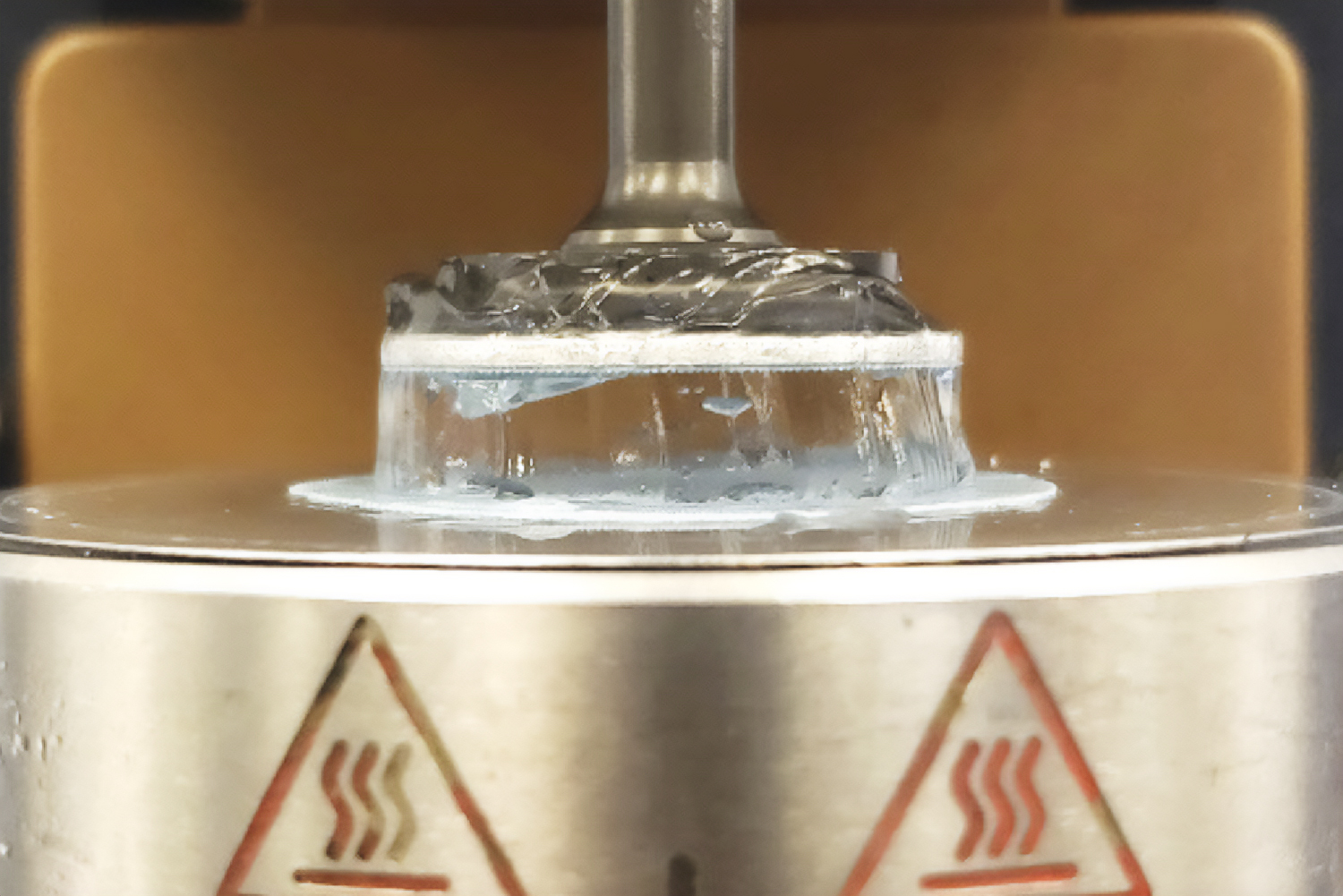

To validate her hypothesis, she conducted experiments with two prevalent soft glassy substances: hair gel and shaving cream. She measured each material using a rheometer — an apparatus comprising two rotating plates that can twist and press a material together at precisely controlled pressures and forces directly relating to the material’s internal stresses and strains.

In her experiments, she placed each material in the rheometer and spun the top plate to mix. Then she allowed the material to settle for a much longer period than merely a minute. During this interval, she noted the force required by the rheometer to maintain the material in place, reasoning that the greater the force exerted by the rheometer, the more it must counteract any stress within the substance that would otherwise promote a shift from its current state.

Through numerous experiments using this novel protocol, Owens discovered that various types of soft glassy materials retained a notable amount of residual stress long after most researchers would believe it had dissipated. Furthermore, she found that the level of stress a material maintained mirrored the direction and timing of its initial mixing.

“The material can effectively ‘remember’ the direction in which it was mixed, and how long ago,” Owens states. “And it turns out they preserve this memory of their past for much longer than we previously thought.”

Along with the protocol she developed to assess residual stress, Owens has constructed a model to predict how a material will evolve over time, considering the amount of residual stress present. She asserts that scientists could design materials with “short-term memory,” or minimal residual stress, enabling them to stay stable over extended periods.

One substance where she envisions potential for such enhancement is asphalt — a material that is initially mixed, then poured in a molten state onto a surface where it cools and settles over time. She suspects that residual stresses from asphalt mixing might play a role in crack formation in roads over time. Reducing these stresses at the onset of the process could yield longer-lasting, more durable streets.

“Inventors are constantly developing new types of asphalt to be more environmentally friendly, and all of these will exhibit varying levels of residual stress requiring management,” she notes. “There’s a vast opportunity for exploration.”

This research was partially supported by MIT’s Postdoctoral Fellowship for Engineering Excellence and an MIT Mathworks Fellowship.

“`