3D-printing metallic components may reduce downtime by weeks, but DARPA seeks a method to validate their lifespan

In an effort to ascertain the expected lifespan of 3D-printed metal components in operational environments, the Defense Advanced Research Projects Agency is allocating up to $10.3M to a team led by the University of Michigan.

When military hardware fails in isolated areas, it may take several weeks for a replacement part sourced from the manufacturer to be delivered. Although 3D printing, particularly via laser powder bed fusion, represents a costly method for creating components, these parts may not possess the same durability as cold-forged alternatives. Nevertheless, downtime incurs even greater costs in terms of lost labor, leading military organizations to consider the possibility of producing parts locally or transporting 3D printers to the field.

The challenge lies in ensuring durability. Military components are subjected to rigorous testing protocols, where the production process is typically so consistent that samples from a single machine can reliably predict the performance of all analogous parts produced by that machine. However, this consistency is lacking in LPBF, where material structure imperfections are more frequent and erratic.

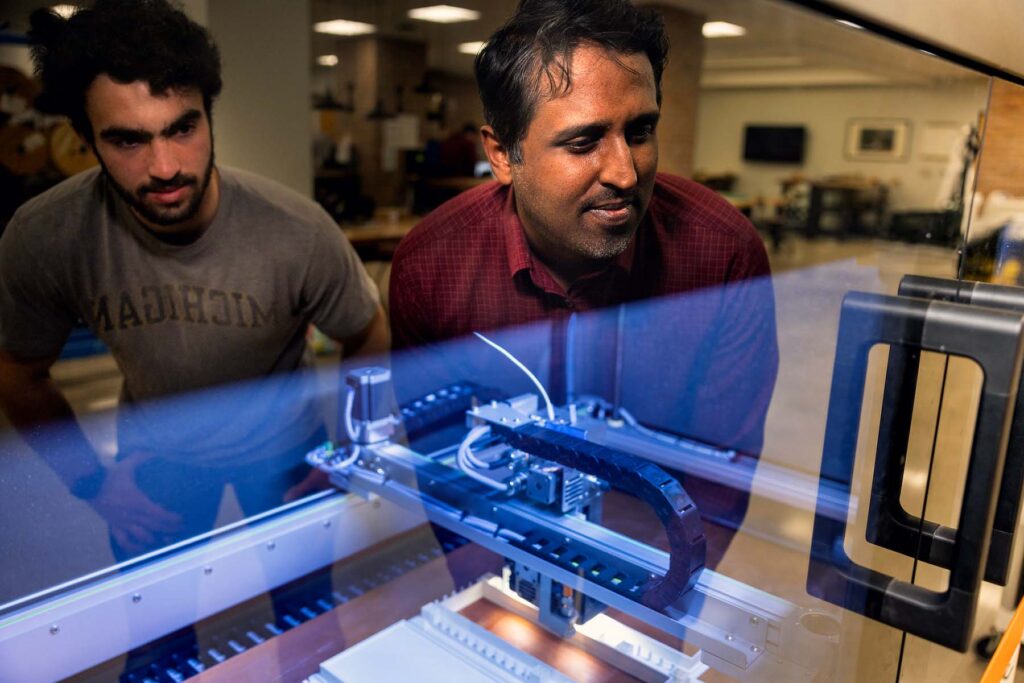

In LPBF, a platform of metal powder is irradiated with lasers, causing it to solidify into a cross-sectional shape. Subsequent layers of powder are applied, and the lasers fuse the following layer to the one beneath it. This process continues until fabrication is complete.

“Depending on the specific LPBF printer model employed, variations in microstructures and properties may arise. Differences in laser spot dimensions and power levels, as well as scanning techniques, can impact the quality of the resultant part,” stated Veera Sundararaghavan, professor of aerospace engineering at U-M and principal investigator of the initiative.

“Our goal is to ensure the integrity of each component as it is produced.”

The approach proposed by Sundararaghavan and his associates involves meticulously documenting the printing process and establishing a digital representation of each component based on emerging defects. Following this, the team will use computational models to simulate recurrent stresses on the part to identify where fractures develop and how long this process takes. These fatigue models can utilize real service data to forecast potential failures in components. The team plans to validate these models through fatigue testing. This four-year effort is titled Predictive Real Time Intelligence for Metal Endurance, or PRIME.

“To comprehend the durability of LPBF components, we must advance the current frontiers of this domain and identify even the most crucial defects that influence component performance. Through the PRIME project, we are achieving just that—utilizing cutting-edge monitoring and AI methodologies to redefine the boundaries of what is achievable,” remarked Mohsen Taheri Andani, assistant professor of mechanical engineering at Texas A&M University and co-leader of the LPBF monitoring initiative.

Three collaborating entities—the additive manufacturing monitoring firm Addiguru, Texas A&M University, and the ASTM Additive Manufacturing Center of Excellence—will devise methods and standards for gathering data during the LPBF production process. They will equip LPBF machines with an optical camera and two infrared cameras to capture near- and far-infrared signals, which will indicate areas where heat accumulates in the sample.

Addiguru is at the forefront of integrating multiple sensors, including an acoustic sensor originally designed to capture birdsong,

However, this system will detect the sounds of porosity flaws within the metal. These instruments will allow the team to pinpoint imperfections as minuscule as 0.025 millimeters, and the sensor suite will be tailored to operate with the majority of LPBF machinery.

“The integration of multisensor data along with sophisticated analytics will deliver essential insights to manufacturers of parts. This initiative will facilitate a thorough, instantaneous evaluation of part quality, enabling producers to make well-informed go/no-go determinations with assurance,” remarked Shuchi “SK” Khurana, the founder and CEO of Addiguru, who is also co-leading the print monitoring efforts.

In addition, a segment of the U-M team will collaborate with the 3D-printing simulation firm AlphaSTAR to utilize this data for creating digital twins of the produced components. Their plan is to merge advanced physics-based modeling of the LPBF process from AlphaSTAR with U-M’s simulations concerning the part’s structure at the microscopic level. The simulations and modeling of the microstructure will additionally assist the group in discerning the residual stresses—forces embedded in the component—that may ultimately lead to its failure.

“The microstructures present in 3D-printed components consist of crystal grains that yield varying properties across different directions, fragile formations known as intermetallic phases, and internal voids distinct from those observed in conventionally manufactured equivalents. Modeling the microstructure will provide vital information for predicting fatigue life,” stated Lei Chen, an associate professor of mechanical engineering at U-M Dearborn, who plays a crucial role in the microstructure modeling initiative.

Lastly, researchers at U-M will also partner with colleagues at the University of California, San Diego, to implement uncertainty quantification models layered on the microstructure models, forecasting the durability of the component over time by digitally evaluating how the metal reacts to the stresses it is likely to face in use. To verify the accuracy of these predictions, Auburn University will conduct fatigue tests on the metal parts, applying stress until they fracture.

“If PRIME is successful, it’s akin to equipping 3D printing with a crystal ball—forecasting the lifespan of LPBF components across platforms and transforming critical part production into a cost-effective, distributed reality,” stated Sundararaghavan.

This project is financed through DARPA’s Structures Uniquely Resolved to Guarantee Endurance program.