The prospect of healthcare could very well hinge on the customization of medical services—understanding precisely what a person requires and subsequently administering the ideal combination of nutrients, metabolites, and medications, if required, to stabilize and enhance their health status. For this to become reality, doctors must first have a method to consistently assess and track specific health biomarkers.

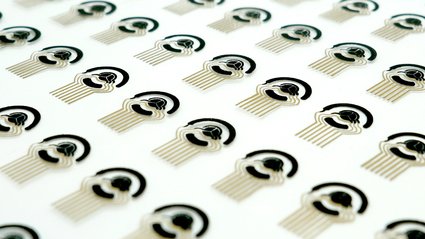

To achieve this, a group of engineers from Caltech has innovated a method for inkjet printing arrays of unique nanoparticles, facilitating the large-scale production of durable wearable sweat sensors. These devices have the potential to monitor various biomarkers, including vitamins, hormones, metabolites, and medications, in real-time, allowing patients and their doctors to continuously observe fluctuations in the concentrations of those substances.

Wearable biosensors utilizing the newly developed nanoparticles have proven effective in tracking metabolites in patients experiencing long COVID and measuring the levels of chemotherapy agents in cancer patients at City of Hope located in Duarte, California.

“These are merely two instances of what is achievable,” remarks Wei Gao, a professor of medical engineering in the Andrew and Peggy Cherng Department of Medical Engineering at Caltech. “Numerous chronic conditions and their biomarkers can now be continually and non-invasively monitored by these sensors,” states Gao, who is the corresponding author of a study published in the journal Nature Materials detailing the innovative method.

Gao and his team describe the nanoparticles as core–shell cubic structures. The cubes develop in a solution containing the substance the researchers aim to observe—for instance, vitamin C. As the monomers spontaneously combine to create a polymer, the targeted substance—vitamin C—gets encapsulated within the cubic nanoparticles. Subsequently, a solvent is applied to specifically extract the vitamin C molecules, leaving a polymer shell with molecular imprints shaped precisely to correspond with the vitamin C molecules—similar to artificial antibodies that selectively identify the forms of certain molecules.

Crucially, in this new research, the scientists integrate those specially crafted polymers with a nickel hexacyanoferrate (NiHCF) nanoparticle core. This material can be oxidized or reduced when subjected to an electrical voltage while in contact with human perspiration or other bodily fluids. Referring back to the vitamin C example, fluid will interact with the NiHCF core as long as the vitamin C-shaped cavities remain vacant, generating an electrical signal.

However, when vitamin C molecules enter the polymer, they settle into those cavities, thus obstructing sweat or other bodily fluids from contacting the core. This diminishes the strength of the electrical signal. Consequently, the intensity of the electrical signal indicates the concentration of vitamin C present.

“The core is essential. The nickel hexacyanoferrate core is exceptionally stable, even in biological fluids, making these sensors perfect for extended measurements,” notes Gao, who is also a Heritage Medical Research Institute Investigator and a Ronald and JoAnne Willens Scholar.

The innovative core-shell nanoparticles are incredibly adaptable and are utilized in printing sensor arrays that can assess levels of multiple amino acids, metabolites, hormones, or drugs in sweat or bodily fluids by simply employing various nanoparticle “inks” within a single array. For instance, in the research discussed in the paper, the team printed nanoparticles that attach to vitamin C alongside other nanoparticles that bond with the amino acid tryptophan and creatinine, a common biomarker used to evaluate kidney function. All of the nanoparticles were merged into one sensor that was then produced on a large scale. These three molecules hold significance in studies concerning patients with long COVID.

In a similar vein, the researchers printed out nanoparticles-based wearable sensors targeting three distinct antitumor drugs on individual sensors, which were subsequently tested on cancer patients at City of Hope.

“Demonstrating the capabilities of this technology, we were able to remotely monitor the concentrations of cancer drugs in the body at any moment,” remarks Gao. “This paves the way for the goal of dose personalization not just for cancer but for numerous other conditions as well.”

In the publication, the team also illustrated that the nanoparticles can be utilized to print sensors that can be implanted beneath the skin to meticulously track drug levels within the body.

The principal authors of the paper, “Printable molecule-selective core–shell nanoparticles for wearable and implantable sensing” are Minqiang Wang and Cui Ye from Caltech. Additional contributors include Yiran Yang (PhD ’23), Daniel Mukasa (MS ’21), Canran Wang (MS ’23), Changhao Xu (PhD ’24), Jihong Min (PhD ’24), Samuel A. Solomon (MS ’23), Jiaobing Tu (PhD ’24), and Songsong Tang from Caltech; Guofang Shen and Jeannine S. McCune from the Beckman Research Institute at City of Hope; and Tzung K. Hsiai and Zhaoping Li from the David Geffen School of Medicine at UCLA. The project was backed by funding from the National Science Foundation, the National Institutes of Health, the American Cancer Society, the Office of Naval Research, the Army Research Office, a NASA Cooperative Agreement, the Heritage Medical Research Institute, and the Caltech-City of Hope Biomedical Initiative. The Kavli Nanoscience Institute at Caltech provided crucial support and infrastructure for this endeavor.