“`html

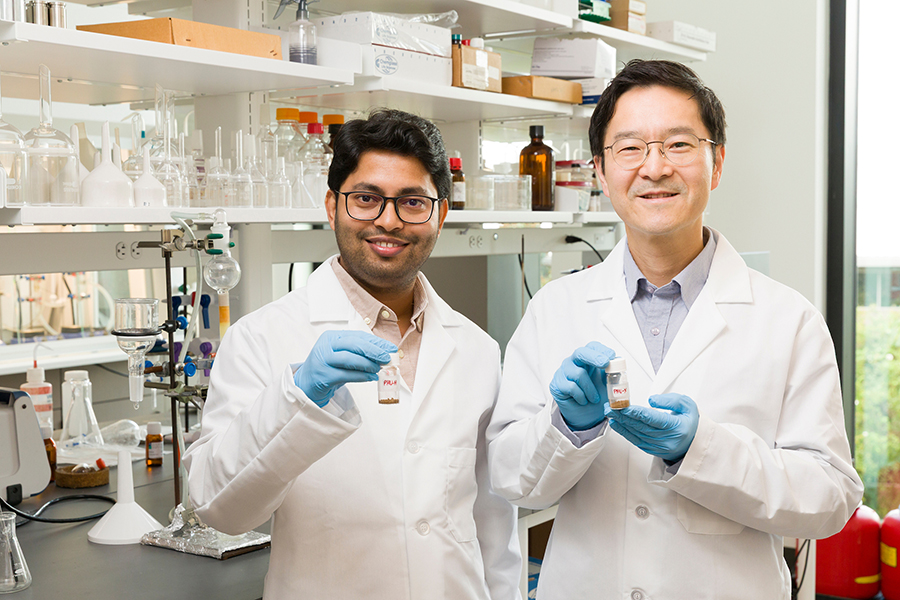

In Ho Yong Chung’s lab, wonders are unfolding — flora transforms into polymers.

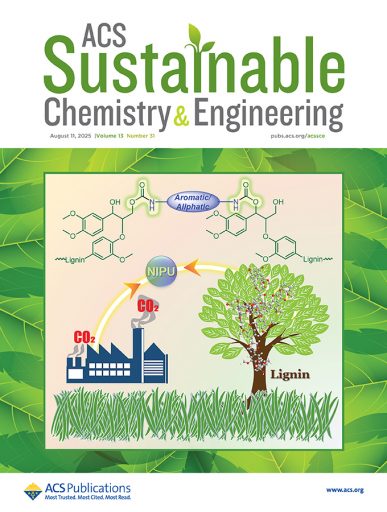

In a recent study, Chung, an associate professor in the FAMU-FSU College of Engineering, demonstrated for the first time the feasibility of utilizing lignin, a substance present in plant cell walls, along with carbon dioxide to produce a new variety of polyurethane, a polymer widely employed for its heat regulation capabilities, adaptability during processing, and strength in final forms.

This research was featured in ACS Sustainable Chemistry & Engineering.

“We’ve developed a top-quality polymer with fewer processes, reduced energy consumption, and no harmful components,” Chung explained. “It’s more beneficial for the environment, improves human health, and simplifies production.”

WHAT THEY ACHIEVED

Conventional polyurethane typically depends on substances known as isocyanates, which are extremely reactive and dangerous. Chung’s approach avoids these entirely. By employing the natural polymer lignin, they formulated a material that is biodegradable, derived from a renewable and underused resource, and steers clear of toxic substances. Their innovation retains the advantages of polyurethane while eliminating its drawbacks.

Although lignin has certain uses in contemporary manufacturing, it is generally regarded as a byproduct of pulp and paper production.

The advancement from Chung’s team yields the same high-performance materials as traditional polyurethanes but utilizes plentiful waste from paper mills and captured carbon dioxide. The end product possesses strength and heat resistance comparable to standard versions while being easily dissolvable in solvents for production.

IMPORTANCE OF THIS RESEARCH

The ease of processing provides this material with a significant edge over other biomass-derived alternatives to petroleum-based plastics.

“Scalability is crucial for us, as we are a polymer science group continually striving to scale up and commercialize our research advancements,” Chung stated. “This offers much better processability compared to other alternatives designed to recreate polyurethane. We utilize significantly fewer reaction steps to manufacture the same or superior quality material. This conserves a substantial amount of energy, which is advantageous for the environment, cost-effectiveness, and efficiency. We incur lower expenses to create the same or higher quality of polyurethane.”

EXPLORING LIGNIN

Chung’s earlier studies have investigated the potential of lignin for producing other varieties of eco-friendly plastics. In research published in 2024, he highlighted its potential for creating polycarbonate, a material from a different polymer category.

This investigation broadens the scope of lignin’s applications by zeroing in on polyurethane. The polymer’s adaptability and elasticity make it more commonly used than polycarbonate.

Chung first became fascinated with lignin during graduate studies when he aimed to develop it as an adhesive. At that time, research in this area was scant. As he began his professional journey, he maintained his focus on lignin due to its potential for breakthroughs in medicine, energy, and sustainable materials.

“Polyurethane is a highly significant material,” Chung remarked. “By creating it through a novel and non-toxic process, we can contribute positively to the world.”

“FSU equipped me with the space, resources, and people necessary to make this happen,” he stated.

COLLABORATORS AND FUNDING

Postdoctoral researcher Arijit Ghorai was the principal author of the study. This inquiry received support from the U.S. Army Research Office and the Ministry of Trade, Industry & Energy of the Republic of Korea.

The post Plastic derived from plants: FAMU-FSU College of Engineering professor employs material in plant cell walls to produce a versatile polymer first appeared on Florida State University News.

“`