“`html

Similar to Middle Eastern petroleum production during the 1970s, China presently leads the worldwide processing of essential metals that form the backbone of the United States economy. In the 1970s, America’s reliance on oil resulted in shortages that hindered growth and caused significant price increases. However, in recent years, U.S. fracking advancements have created a novel approach to extracting oil, changing the nation from one of the largest oil importers to one of the foremost exporters.

Currently, the U.S. requires another technological advancement to secure domestic sources of metals such as lithium, cobalt, copper, and rare earth elements, which are vital for a variety of applications ranging from batteries to jet engines and electric motors. Nth Cycle believes it possesses the answer.

The firm was co-established by MIT Associate Professor Desirée Plata, CEO Megan O’Connor, and Chief Scientist Chad Vecitis to reclaim essential metals from industrial waste and ores utilizing a patented, highly efficient technique known as electro-extraction.

“America is a remarkably resource-abundant nation — it’s merely a matter of extracting and transforming those resources for utilization. That’s the function of refining,” states O’Connor, who engaged in electro-extraction as a PhD student with Plata when they both attended Duke University. “By bridging that gap in the supply chain, we can position the United States as the leading producer of essential metals globally.”

Since last year, Nth Cycle has been producing cobalt and nickel using its initial commercial system in Fairfield, Ohio. The company’s modular refining systems, which operate on electricity rather than fossil fuels, can be set up in a fraction of the time required by conventional metal refining facilities. Now, Nth Cycle plans to implement its modular systems across the United States and Europe to develop new supply chains for the materials that fuel our economy.

“Approximately 85 percent of the world’s vital minerals are processed in China, which poses both an economic and national security concern for us,” O’Connor comments. “Even if we extract the materials here — we do have one functioning nickel mine in Michigan — we then export it abroad for refining. These materials are essential components of various sectors. Everything from our smartphones to our vehicles to our defense systems relies on them. I often remark that critical minerals are akin to the new oil.”

From waste, an opportunity

In 2014, O’Connor and Plata attended a lecture by Vecitis, then a professor at Harvard University, where he discussed his research utilizing electrochemical filters to eliminate contaminants in pharmaceutical wastewater. During the research, he observed that the material was interacting with metal to form crystalline copper in the filters. Following the presentation, Plata inquired whether Vecitis had ever considered employing the method for metal separation. He hadn’t, but he was eager to explore.

At that time, Plata and O’Connor were investigating mineral-rich wastewater generated as a byproduct of hydraulic fracturing for oil and gas.

“The initial thought was: Could we utilize this technology to extract those metals?” O’Connor remembers.

Attention shifted towards applying the technology to recover metals from electronic waste, including sources like old phones, electric vehicles, and smartwatches.

Today, manufacturers and electronic waste facilities pulverize end-of-life materials and transport them to large chemical refineries overseas, which heat the metal into a molten state and subject it to a series of acids and bases to purify the waste back into its desired metal form.

“Each of those acids and bases need to be transported as hazardous materials, and the production of them has a substantial greenhouse gas and energy footprint,” Plata clarifies. “This complicates the economics for anything other than large, centralized facilities — and even then, it remains a challenge.”

The United States and Europe have a wealth of end-of-life scrap material, but it is dispersed, and environmental regulations have left the West with limited scalable refining opportunities.

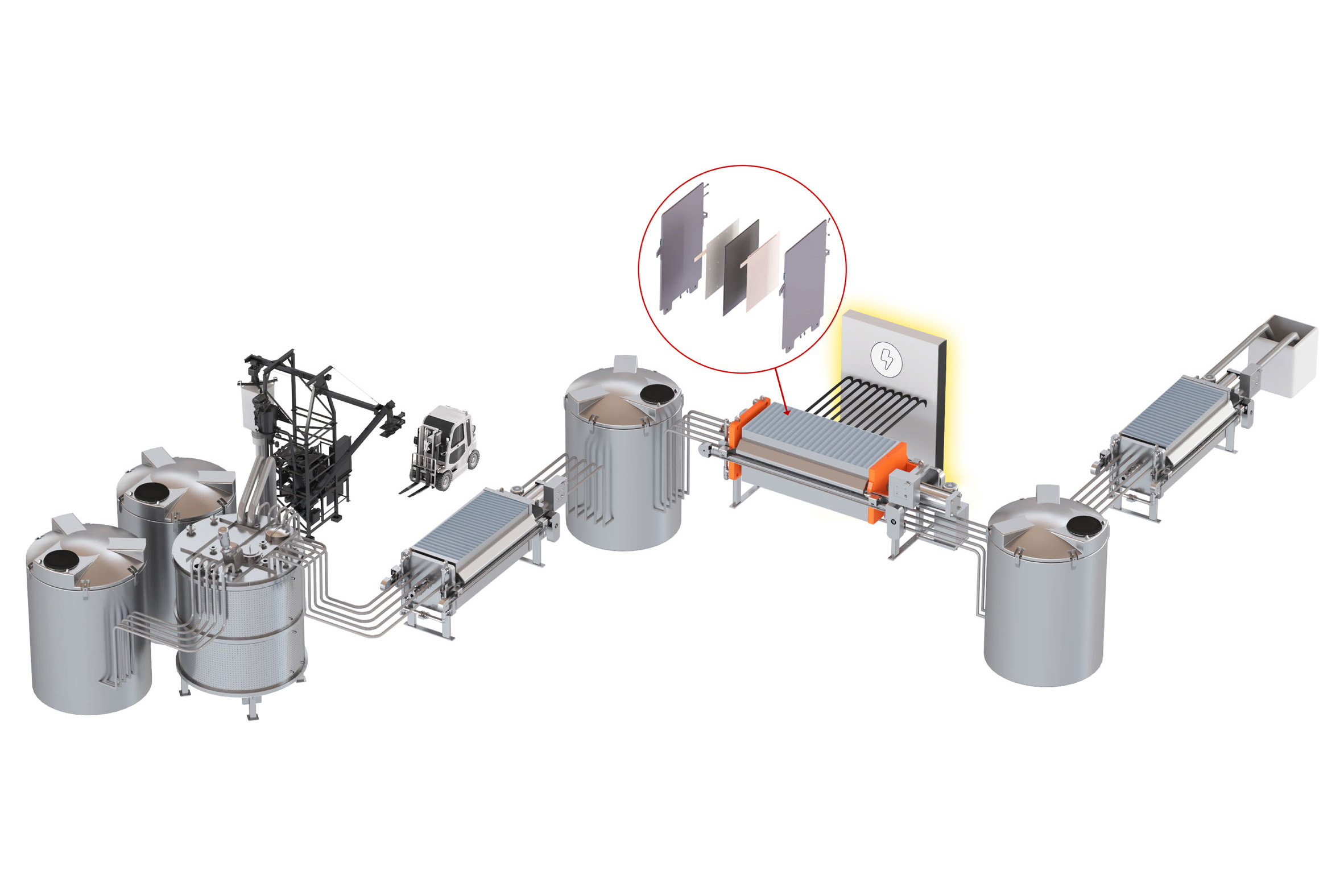

Rather than constructing a refinery, Nth Cycle’s team has developed a modular refining system — called “The Oyster” — which can decrease costs, waste, and time-to-market by being co-located on-site with recyclers, miners, and manufacturers. The Oyster employs electricity, chemical precipitation, and filtration to produce the same metal refining chemicals as traditional methods. Currently, the system can process more than 3,000 metric tons of scrap annually and can be tailored to produce various metals.

“Electro-extraction is among the cleanest methods to recover metal,” Plata states.

Nth Cycle received initial support from the U.S. Department of Energy, and when Plata joined MIT in 2018, Nth Cycle became part of the MIT Industrial Liaison Program’s STEX25 startup accelerator.

“What’s particularly significant about being in a place like MIT is the entrepreneurial ecosystem and the ‘tough tech’ ethos of Cambridge,” Plata explains. “That has been immensely beneficial to Nth Cycle’s success and one of the reasons we relocated the company to the greater Boston area. Being able to access talent and patient capital was crucial.”

Onshoring metal refining

Plata mentions that one of the most gratifying moments of her career occurred last year at the groundbreaking event for Nth Cycle’s initial mixed hydroxide (nickel and cobalt) production facility in Ohio. Many of Nth Cycle’s new employees at the facility had previously worked at automotive and chemical plants in the town but are now part of what Nth Cycle refers to as the first commercial nickel refining facility for scrap in the nation.

“O’Connor’s vision of uplifting individuals while enhancing the economy is an inspiring benchmark,” Plata states.

Nth Cycle will own and operate additional Oyster systems within a business model O’Connor describes as refining as a service, wherein customers retain ownership of the final product. The company seeks to collaborate with scrap yards and industrial scrap collection facilities, as well as manufacturers that produce waste.

Nth Cycle is primarily focused on recovering metals from batteries today, but it has also utilized its technique to recover cobalt and nickel from spent catalyst material in the oil and gas sector. Looking ahead, Nth Cycle hopes to apply its process to the largest waste sources of all: mining.

“The world needs an increased supply of essential minerals like cobalt, nickel, lithium, and copper,” O’Connor states. “The only two sources for those materials are recycling and mining, and both sources require chemical refining. That’s where Nth Cycle steps in. Many people harbor a negative perception of mining, but with a technology that can minimize waste and emissions, that’s how you encourage more mining in regions like the U.S. That’s the impact we aspire for this technology to have in the Western world.”

“`