“`html

The current surge in electric vehicles is set to create a future surplus of electronic waste. Although numerous initiatives are in progress to enhance battery recycling methods, a significant number of EV batteries are still discarded in landfills.

Researchers from MIT aim to alter this scenario by introducing a novel type of self-assembling battery material that disassembles quickly when placed in a basic organic liquid. In a recent study published in Nature Chemistry, the team demonstrated that the material can function as the electrolyte in a working solid-state battery cell and subsequently revert to its original molecular building blocks in a matter of minutes.

This technique presents an alternative to pulverizing the battery into a heterogeneous, difficult-to-recycle mixture. Instead, since the electrolyte acts as the connective layer in the battery, when the new substance returns to its initial molecular state, the entire battery disassembles, thereby streamlining the recycling efforts.

“So far in the battery sector, we’ve concentrated on high-efficiency materials and designs, only to address recycling later for batteries constructed with intricate structures and not easily recyclable components,” states the study’s primary author Yukio Cho PhD ’23. “Our strategy is to begin with readily recyclable substances and determine how to adapt them for battery use. Creating batteries with recyclability in mind from the outset is an innovative method.”

Collaborating with Cho on this paper are PhD candidate Cole Fincher, Ty Christoff-Tempesta PhD ’22, Kyocera Professor of Ceramics Yet-Ming Chiang, Visiting Associate Professor Julia Ortony, Xiaobing Zuo, and Guillaume Lamour.

Improved batteries

There’s a memorable scene in one of the “Harry Potter” films where Professor Dumbledore tidies a run-down house with just a flick of his wrist and a spell. Cho recalls this image resonating with him as a child. (What better method to tidy your space?) Upon witnessing a lecture by Ortony about engineering molecules to self-assemble into complex formations and then revert to their initial state, he contemplated whether this could be applied to make battery recycling seem magical.

This would represent a revolutionary change for the battery sector. Presently, recycling batteries necessitates harsh chemicals, extreme temperatures, and intricate procedures. A battery typically comprises three primary components: the positively charged cathode, the negatively charged electrode, and the electrolyte facilitating the movement of lithium ions between them. The electrolytes found in most lithium-ion batteries are highly combustible and degrade over time into hazardous byproducts that require specialized handling.

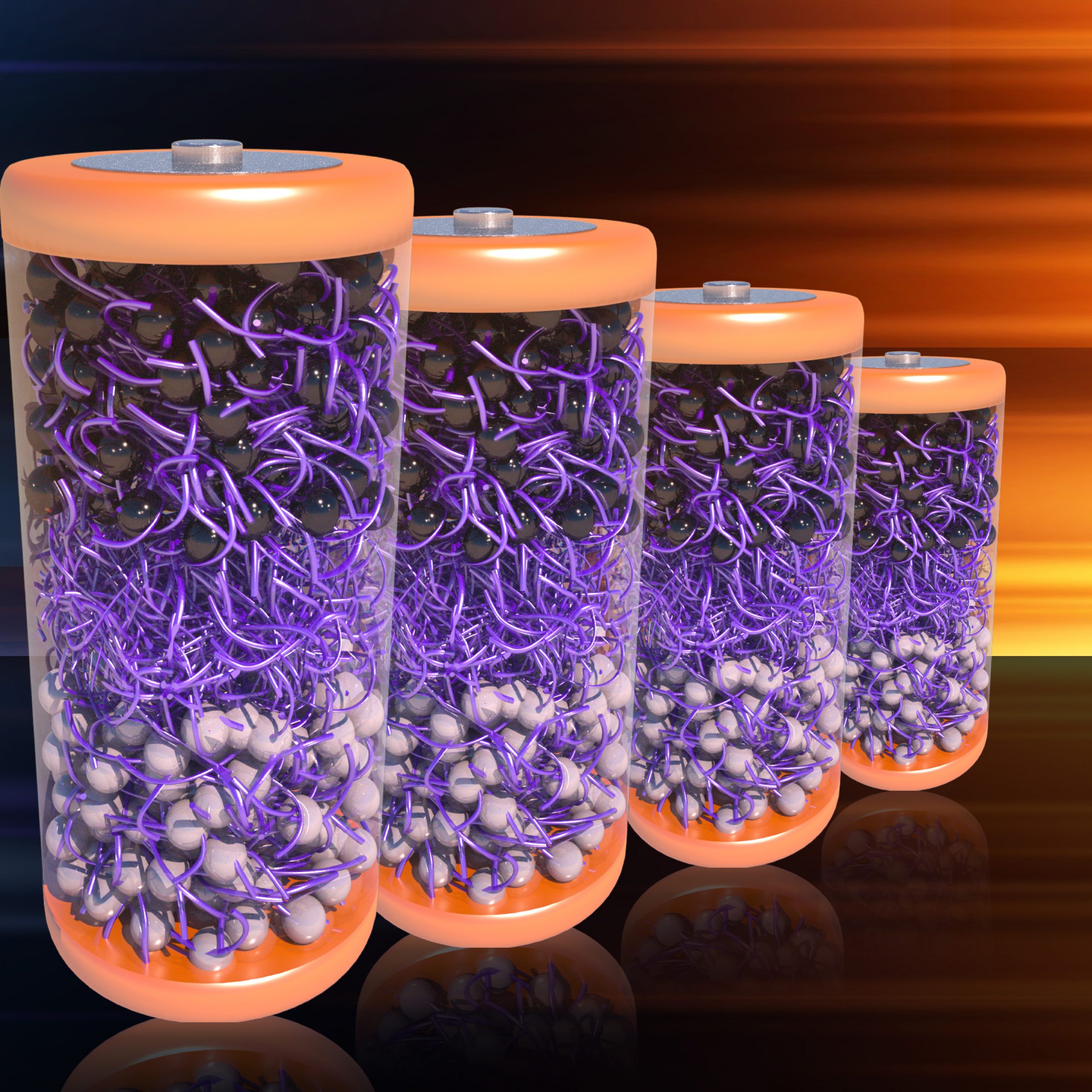

To simplify the recycling procedure, the researchers opted to create a more eco-friendly electrolyte. They focused on a class of molecules known as aramid amphiphiles (AAs), which self-assemble in water and exhibit chemical structures and stability akin to Kevlar. They further modified the AAs to incorporate polyethylene glycol (PEG), capable of conducting lithium ions, at one end of each molecule. When these molecules come in contact with water, they spontaneously form nanoribbons with surfaces conducting ions through PEG and bases mimicking the sturdiness of Kevlar via tight hydrogen bonding. The outcome is a mechanically sound nanoribbon structure that facilitates ion conduction across its surface.

“The material consists of two segments,” Cho explains. “The first segment is a flexible chain that provides a host for lithium ions to navigate. The second segment is a robust organic material component used in Kevlar, which is known for its bulletproof qualities. Together, these create a stable structure.”

When introduced to water, the nanoribbons self-assemble into millions of strands that can be hot-pressed into a solid-state material.

“Within five minutes of being introduced to water, the mixture transforms into a gel-like consistency, indicating that numerous nanofibers have formed in the liquid and started entangling with one another,” Cho states. “The exciting part is that we can produce this material at scale due to its self-assembly properties.”

The team assessed the material’s durability and resilience, discovering it could withstand the pressures associated with the battery’s creation and operation. They also built a solid-state battery cell utilizing lithium iron phosphate for the cathode and lithium titanium oxide for the anode, both commonly used materials in contemporary batteries. The nanoribbons successfully transported lithium ions between the electrodes, although a phenomenon known as polarization hindered the flow of lithium ions into the battery’s electrodes during rapid charging and discharging, limiting its efficiency in comparison to current top-performing commercial batteries.

“The lithium ions moved along the nanofiber effectively, but the challenge lies in transferring the lithium ion from the nanofibers to the metal oxide, which appears to be the most sluggish aspect of the process,” remarks Cho.

When they submerged the battery cell in organic solvents, the material rapidly dissolved, allowing each component of the battery to detach for simpler recycling. Cho likened the materials’ reaction to cotton candy dissolving in water.

“The electrolyte connects the two battery electrodes and creates pathways for lithium ions,” Cho explains. “Therefore, when it’s time to recycle the battery, the entire electrolyte layer can naturally separate, allowing for the independent recycling of the electrodes.”

Confirming an innovative method

Cho affirms that the material serves as a proof of concept showcasing the recycle-first approach.

“We don’t claim we have resolved every issue associated with this material,” Cho asserts. “Our battery performance wasn’t exceptional since we relied solely on this material for the entire electrolyte in the research, but what we envision is employing this material as one layer within the battery electrolyte. It doesn’t need to constitute the entire electrolyte to initiate the recycling process.”

Cho also recognizes substantial potential for enhancing the material’s functionality through further research.

Currently, the researchers are investigating opportunities to incorporate these types of materials into existing battery designs alongside applying these concepts to new battery chemistries.

“It’s quite challenging to persuade current manufacturers to adopt radically different approaches,” Cho states. “However, with emerging battery materials expected to surface in five to ten years, integrating this into new designs from the outset may be more feasible.”

Cho also believes this method could assist in resourcing lithium supplies by reutilizing materials from batteries already present within the U.S.

“People are beginning to recognize how crucial this is,” Cho states. “If we can initiate large-scale recycling of lithium-ion batteries from battery waste, it will have a similar effect to launching lithium mines domestically. Moreover, as each battery requires a specific quantity of lithium, based on the anticipated growth of electric vehicles, we must repurpose this material to prevent significant spikes in lithium prices.”

The research received partial support from the National Science Foundation and the U.S. Department of Energy.

“`