As the highly pathogenic H5N1 avian influenza continues to disseminate across the U.S., presenting significant challenges to dairy and poultry farms, both agricultural producers and public health authorities require enhanced methods to detect infections in real time, aiming to mitigate and address outbreaks effectively. Thanks to investigations from Washington University in St. Louis, which were published in a dedicated edition of ACS Sensors focusing on “breath sensing,” virus monitors now possess tools to track aerosolized H5N1 particles.

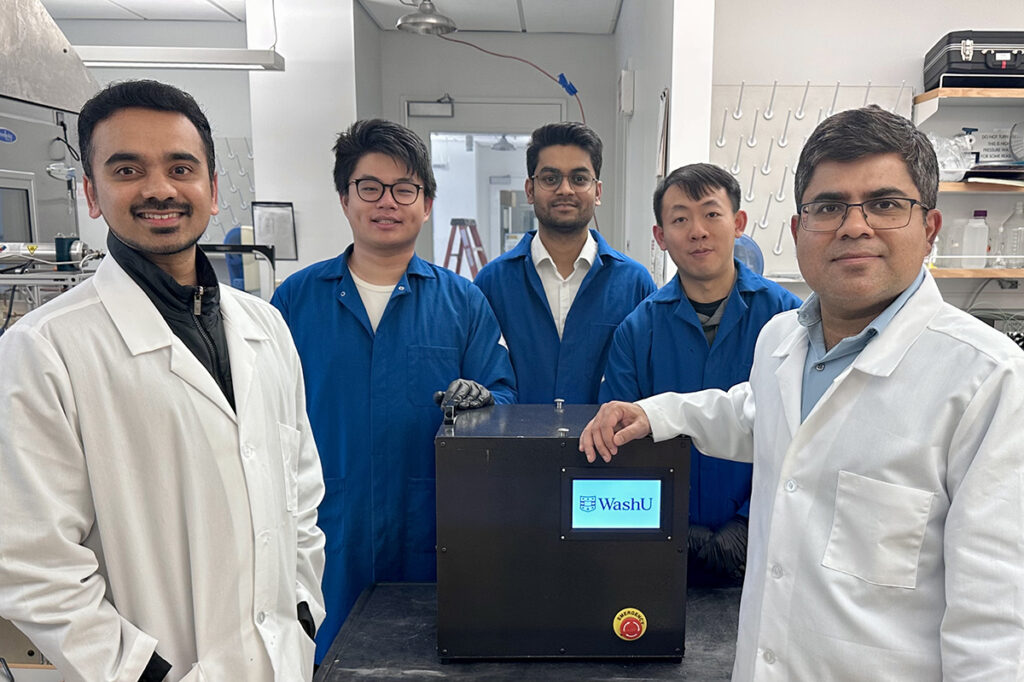

To design their avian flu sensor, researchers within Rajan Chakrabarty’s laboratory, a professor of energy, environmental, and chemical engineering at WashU’s McKelvey School of Engineering, utilized electrochemical capacitive biosensors to enhance the speed and sensitivity of detecting viruses and bacteria.

The timing of their research is crucial as the avian virus has alarmingly evolved over the past year, now transmitting through airborne particles to mammals, including humans. The virus has already been proven fatal in felines, and there has been at least one reported incident of a human fatality due to H5N1.

“This biosensor represents the first of its kind,” remarked Chakrabarty, referencing the technology deployed for detecting airborne virus and bacteria particles. Previously, scientists relied on slower detection techniques involving polymerase chain reaction DNA tools.

Chakrabarty pointed out that traditional testing methods can exceed 10 hours — “far too long to contain an outbreak.”

The innovative biosensor operates within five minutes, preserving the microbial sample for further examination and offering various pathogen concentration levels detected on a farm. This capability facilitates prompt intervention, according to Chakrabarty.

Time is critical when averting a viral outbreak. At the inception of this research project, H5N1 could only be transmitted through contact with infected avians.

“As this paper progressed, so did the virus; it underwent mutations,” Chakrabarty added.

The U.S. monitors animal health and pathogen outbreaks on farms through the U.S. Department of Agriculture Animal and Plant Health Inspection Service (APHIS), which recently reported that over the last 30 days, there have been at least 35 new dairy cattle instances of H5N1 across four states, primarily in California.

“The strains this time are remarkably different,” Chakrabarty noted.

If farmers suspect an infection, they can send the animal to laboratories of the state agriculture department for analysis. However, this process can be slow and further hindered by a backlog of cases as H5N1 spreads through poultry and dairy farms. Mitigation strategies include biosecurity practices such as isolating animals, disinfecting facilities and equipment, and enforcing protective measures to limit animal exposure, which may include large-scale culling. The USDA also recently granted a conditional license for an avian influenza vaccine, which could offer further support to poultry producers looking to reduce egg costs.

Chakrabarty is eager to present this biosensor to the world, stating that it was designed to be portable and economical for mass production.

How it operates

The integrated pathogen sampling-sensing device resembles the size of a desktop printer and can be positioned where farms expel exhaust from poultry or cattle housing. This unit is a remarkable feat of interdisciplinary engineering comprising a “wet cyclone bioaerosol sampler” that was originally crafted for sample collection of SARS-CoV-2 aerosols.

The air burdened with pathogens enters the sampler at significantly high speeds and is blended with the fluid lining the sampler’s interior to create a surface vortex, effectively trapping the virus aerosols. The unit features an automated pumping system that transfers the sampled fluid every five minutes to the biosensor for uninterrupted virus detection.

Meng Wu, Chakrabarty’s senior staff scientist, and graduate student Joshin Kumar undertook the meticulous task of refining the surface of the electrochemical biosensor to enhance its sensitivity and stability for detecting trace amounts of the virus (fewer than 100 viral RNA copies per cubic meter of air).

The biosensor employs “capture probes” known as aptamers, which consist of single strands of DNA that attach to virus proteins, signaling their presence. The major challenge for the team was to make these aptamers effective with the 2-millimeter surface of an uncoated carbon electrode in identifying the pathogens.

After months filled with experimentation, the team discovered the correct combination for modifying the carbon surface using a blend of graphene oxide and Prussian blue nanocrystals to boost the biosensor’s sensitivity and stability. The concluding step involved connecting the altered electrode surface to the aptamer using crosslinker glutaraldehyde, which Xu and Kumar described as the “secret sauce” for functionalizing the surface of a bare carbon electrode to detect H5N1.

They mentioned that a significant advantage of the team’s detection method is its nondestructive nature. Post-testing for the virus’s presence, the sample can be preserved for additional analysis through traditional methods such as PCR.

The integrated pathogen sampling-sensing unit operates autonomously — no biochemistry expertise is required for its use. It is constructed with inexpensive and easily mass-producible materials. The biosensor can deliver concentration ranges of H5N1 in the air and notify operators of disease surges in real time. Xu indicated that knowledge of these levels can serve as a general indicator of “threat” in a facility and inform operators if the pathogen balance has shifted to hazardous levels.

This capability to provide a virus concentration range marks another groundbreaking achievement for sensor technology. Most crucially, it possesses the potential for scaling to detect numerous other hazardous pathogens using one device.

“This biosensor is tailored for H5N1, but it can also be adapted to identify other influenza virus strains (e.g., H1N1) and SARS-CoV-2, in addition to bacteria (E. coli and pseudomonas) in the aerosol phase,” remarked Chakrabarty. “We have demonstrated the functionalities of our biosensor and documented our discoveries in the publication.”

The team is currently working on bringing the biosensor to market. Varro Life Sciences, a biotech firm in St. Louis, has consulted with the research group during the biosensor’s development phases to facilitate potential commercial opportunities in the future.

Kumar J, Xu M, Li YA, You SW, Doherty BM, Gardiner WD, Cirrito JR, Yuede CM, Benegal A, Vahey MD, Joshi A, Seehra K, Boon ACM, Huang YY, Puthussery JV, Chakrabarty R. Capacitive Biosensor for Rapid Detection of Avian (H5N1) Influenza and E. coli in Aerosols. ACS Sensors, online Feb. 21. DOI: https://pubs.acs.org/doi/10.1021/acssensors.4c03087

Funding for this research was supplied by Flu Lab.

The article New biosensor can detect airborne bird flu in under five minutes appeared first on The Source.