“`html

Hearing devices, dental guards, dental implants, and other specifically designed entities are frequently products of 3D printing technology. These items are usually fabricated through vat photopolymerization — a technique of 3D printing that employs light patterns to mold and harden a resin, layer by layer.

The procedure also entails printing structural supports from the identical material to stabilize the item during its creation. Once the item is completely formed, the supports are manually detached and generally discarded as non-recyclable waste.

Engineers at MIT have discovered a method to eliminate this final step, potentially accelerating the 3D-printing procedure significantly. They formulated a resin that transitions into two distinct types of solids, influenced by the kind of light that illuminates it: Ultraviolet light solidifies the resin into a robust structure, while visible light transforms the same resin into a form that readily dissolves in specific solvents.

The team exposed the innovative resin to both UV light patterns to construct a durable structure and visible light patterns to create the structure’s supports. Rather than meticulously breaking away the supports, they simply immersed the printed material in a solution that dissolved the supports, unveiling the sturdy, UV-cured component.

The supports can dissolve in various food-safe solutions, including baby oil. Notably, the supports can also dissolve in the primary liquid component of the original resin, like a cube of ice in water. This indicates that the material used for printing supports could be endlessly recycled: Once the supporting material of a printed structure dissolves, the mixture can be blended back into fresh resin and utilized for creating the next parts — along with their dissolvable supports.

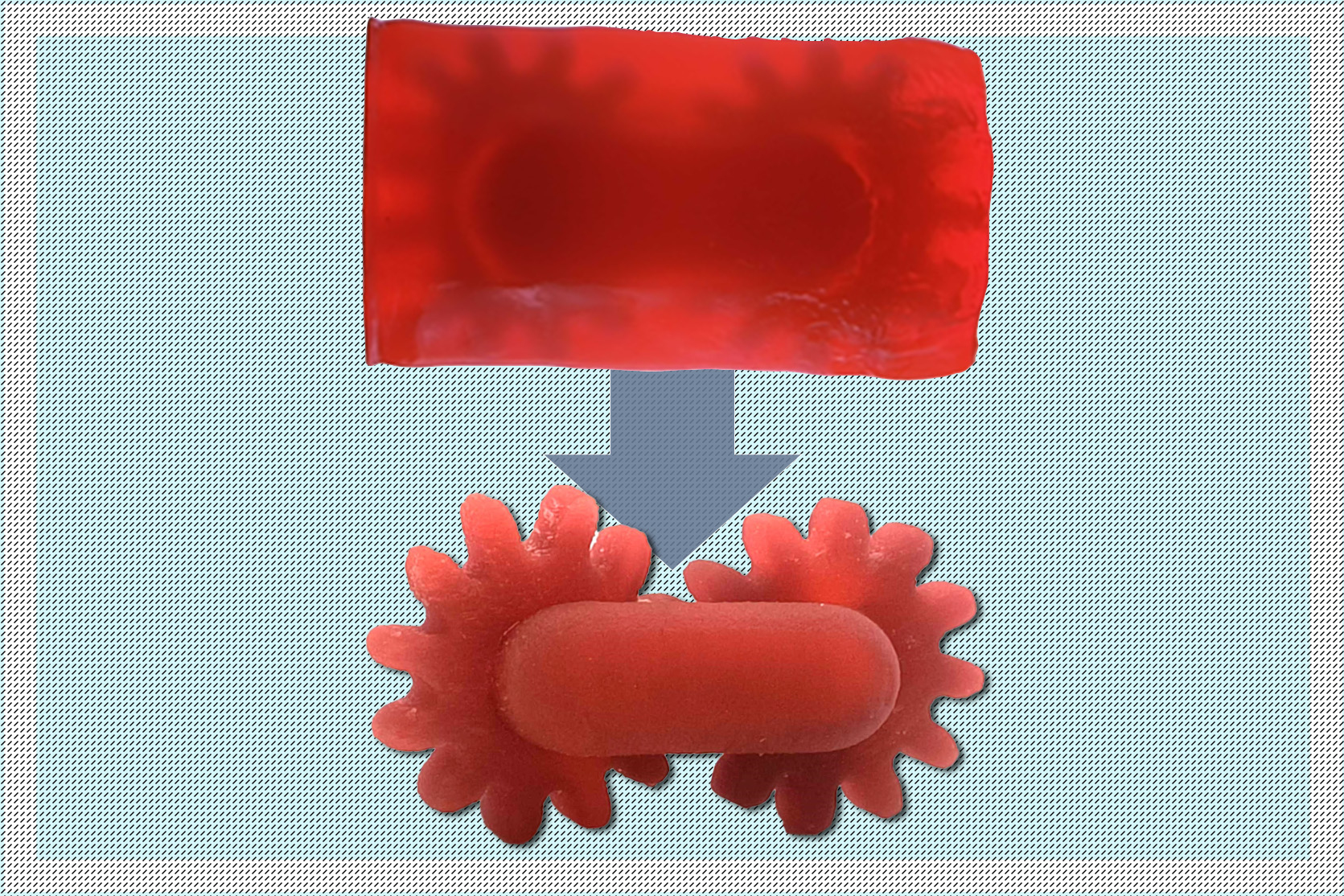

The researchers employed this new technique to fabricate complex structures, such as functional gear systems and detailed lattices.

“You can now produce — in a single print — multi-part, functional assemblies with moving or interlocking elements, and you can essentially wash away the supports,” says graduate student Nicholas Diaco. “Instead of discarding this material, you can recycle it right on-site and generate much less waste. That’s the ultimate goal.”

He and his colleagues present the specifics of this method in a publication released today in Advanced Materials Technologies. The co-authors of the MIT study include Carl Thrasher, Max Hughes, Kevin Zhou, Michael Durso, Saechow Yap, Professor Robert Macfarlane, and Professor A. John Hart, head of MIT’s Department of Mechanical Engineering.

Waste elimination

Traditional vat photopolymerization (VP) initiates with a 3D computer model of the intended structure — for example, two interlocking gears. In addition to the gears themselves, the model incorporates small supporting structures around, below, and amid the gears to ensure every feature remains in position during printing. This computer model is then sliced into numerous digital layers sent to a VP printer for production.

A typical VP printer comprises a small vat of liquid resin located above a light source. Each slice of the model is converted into a corresponding light pattern projected onto the liquid resin, resulting in solidification into the same design. Layer by layer, a solid, light-printed version of the model’s gears and supports gradually forms on the build platform. When printing concludes, the platform elevates the completed part above the resin bath. Once excess resin is washed away, an individual can manually remove the intermediary supports, usually by cutting and filing, and the support material is ultimately discarded.

“For the most part, these supports result in significant waste,” Diaco states.

Print and dip

Diaco and the team sought a method to streamline and hasten the removal of printed supports, ideally allowing for their recycling. They devised a general idea for a resin that can assume one of two phases based on light exposure: a sturdy phase forming the desired 3D structure and a secondary phase serving as a supporting material that could also be easily dissolved.

After experimenting with some chemical combinations, the team discovered they could create such a two-phase resin by blending two commercially accessible monomers, the chemical building blocks found in various types of plastic. When ultraviolet light illuminates the mixture, the monomers bond into a tightly intertwined network, resulting in a durable solid that resists dissolution. Under visible light, the same monomers still cure, but at the molecular level, the newly formed monomer strands remain distinct from one another. This solid can rapidly dissolve when introduced to specific solutions.

In initial experiments with small vials of the new resin, the researchers confirmed the substance converts into both insoluble and soluble forms in response to ultraviolet and visible light, respectively. However, when they progressed to a 3D printer employing LEDs less powerful than the benchtop arrangement, the UV-hardened material disintegrated in solution. The reduced light only partially bonded the monomer strands, leaving them insufficiently tangled to maintain the structure’s integrity.

Diaco and his colleagues discovered that adding a minor amount of a third “bridging” monomer could connect the two initial monomers under UV light, knitting them into a considerably more durable framework. This adjustment enabled the researchers to print resilient 3D structures along with dissolvable supports using synchronized pulses of UV and visible light in one operation.

The team utilized this new technique to print a variety of complex structures, including interlocking gears, elaborate lattices, a ball within a square frame, and, for entertainment, a small dinosaur encased in an egg-shaped support that dissolved away when submerged in solution.

“For all these structures, you require a lattice of supports inside and out while printing,” Diaco explains. “Removing those supports typically necessitates careful, manual extraction. This demonstrates we can print multi-part assemblies with numerous moving components and detailed, customized products like hearing devices and dental implants in a manner that’s quick and sustainable.”

“We will continue investigating the limitations of this method, and we aim to develop additional resins with this wavelength-selective behavior and the mechanical properties required for durable products,” states mechanical engineering professor John Hart. “Along with automated part handling and closed-loop reuse of the dissolved resin, this represents an exciting pathway to resource-saving and cost-efficient polymer 3D printing at scale.”

This research received partial support from the Center for Perceptual and Interactive Intelligence (InnoHK) in Hong Kong, the U.S. National Science Foundation, the U.S. Office of Naval Research, and the U.S. Army Research Office.

“`