“`html

A novel specimen holder provides researchers enhanced control over ultracold conditions, facilitating the examination of how materials develop traits beneficial for quantum computers

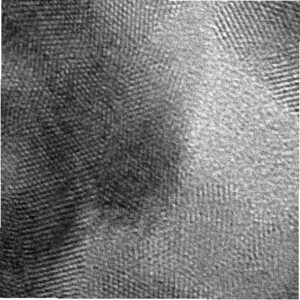

Researchers can now consistently cool specimens to near absolute zero for more than 10 hours while capturing images resolved at the atomic level using an electron microscope.

This advanced ability originates from a liquid-helium-cooled sample holder devised by a consortium of scientists and engineers from the University of Michigan and Harvard University, whose research received federal support from the Department of Energy and the National Science Foundation.

Traditional devices can typically maintain such extreme temperatures, roughly -423 degrees Fahrenheit or 36 degrees above absolute zero, for only a few minutes, often maxing out at just a couple of hours. Extended durations are essential for capturing atomic-resolution images of potential materials for cutting-edge technologies.

These materials include superconductors that transmit electricity without heat losses, quantum computers that could operate millions of times faster than current computers for certain calculations, and neuromorphic systems that enhance speed and efficiency by emulating human brain functions. Such candidate materials usually do not exhibit their peculiar and advantageous traits unless subjected to extreme cold.

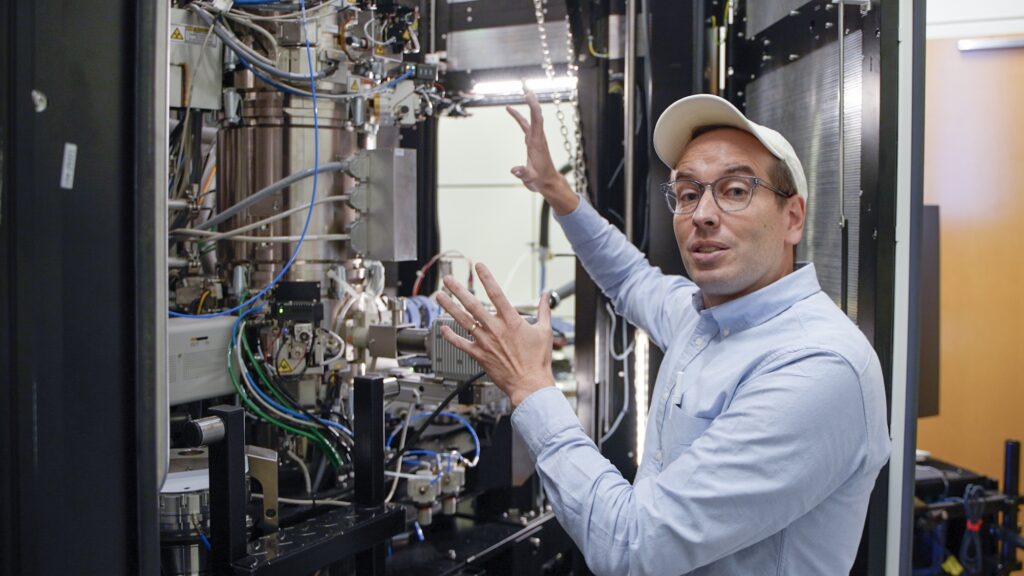

“When atoms approach such frigid temperatures, they exhibit minimal motion, which drastically alters the material’s properties,” stated Robert Hovden, an associate professor at U-M in materials science and engineering and the study’s corresponding author published in the Proceedings of the National Academy of Sciences.

“A myriad of fascinating phenomena occurs. Metals may transition into insulators or superconductors, allowing us to develop qubits and innovative memory systems around them,” he added. “To comprehend how these characteristics develop, we must observe materials at those low temperatures for the entire length of an experiment.”

While ultracold microscopy at -321 F (77 Kelvin) has permitted scientists to capture images of materials and proteins resolved to the atomic level, more frigid conditions are necessary to visualize certain quantum properties and achieve elevated resolutions. Liquid helium could lower temperatures even further, approaching absolute zero (0 K, -460 F), as helium condenses around -452 F (4 K).

However, practical challenges have hindered scientists from utilizing liquid helium with a microscope for extended durations. In most modern transmission electron microscopy systems, the sample is held under a microscope connected to a dewar, a thermos-like vessel. The dewar cools both the rod and the sample when filled with a super-chilled liquid, typically nitrogen or helium, which rapidly boils inside the dewar, disturbing the sample and diminishing image clarity. These challenges are exacerbated with liquid helium due to its more vigorous boiling and quicker evaporation.

“It’s akin to pouring water onto hot magma,” Hovden remarked. “Not only do you experience numerous vibrations from the bubbling liquid, but the temperature fluctuates significantly, causing the rod to contract and making it impossible to maintain the exact temperature required.”

The instrument developed by the researchers can sustain sample temperatures as low as -423 degrees Fahrenheit (20 Kelvin) for more than 10 hours, with only 0.004 degrees Fahrenheit (0.002 Kelvin) of fluctuation. This degree of precision, which is 10 times superior to current instruments, enables scientists to subject a sample to a meticulously controlled temperature gradient while observing how its properties evolve under the microscope.

“Having the ability to visualize the atomic configuration as the substance transforms might be crucial for comprehending and utilizing the atomic and nanoscale phenomena that render quantum materials their extraordinary characteristics,” stated Ismail El Baggari, a materials physicist at Harvard University’s Rowland Institute and a co-author of the research.

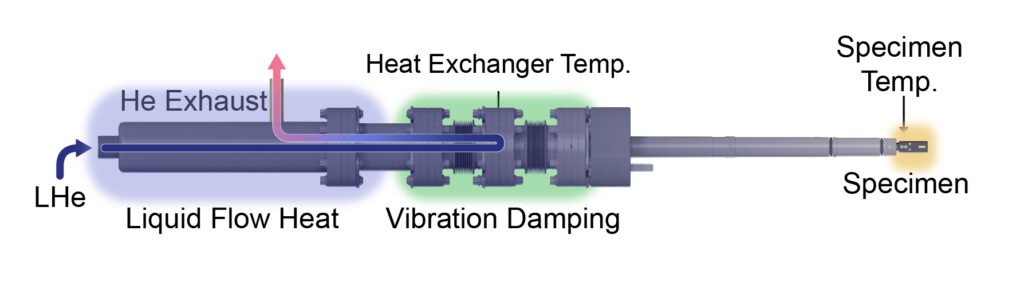

The apparatus’s consistent cooling is facilitated by a heat exchanger connected to the sample holder. The helium vaporizes as it is drawn through the heat exchanger, lowering the temperature of the sample before it exits via an exhaust port. Current closed-loop sample holders also use helium to chill specimens; however, they produce too much vibration for images that are resolved to the atomic scale. In the redesigned system, elastic, adaptable tubing and rubber dampeners at both ends of the heat exchanger minimize the vibrations generated by the evaporating helium, ensuring the acquisition of high-resolution images.

This delicate procedure demands precise mechanical specifications. Even minor variances from the designs can lead to excessive vibrations or leaks.

“Determining how to construct this device and evaluate it within the microscope were significant challenges to address,” remarked Emily Rennich, the primary author of the study, who spearheaded the development of the device while pursuing her bachelor’s degree in mechanical engineering at U-M.

“I initially lacked extensive manufacturing or design expertise before I began this project. It was only through extensive trial and error, along with discussions with other machinists, that we succeeded in creating a functional apparatus,” expressed Rennich, who is now a PhD candidate in mechanical engineering at Stanford University.

The innovation is already in use at the Michigan Center for Materials Characterization, which operates with funding support from indirect cost allocations within federal grants. This new system allows researchers nationwide to conduct experiments that were previously unattainable.

“I’m thrilled about this advancement, something I’ve been looking forward to for almost a decade,” said Miaofang Chi, a corporate fellow at Oakridge National Laboratory and a professor of mechanical engineering and materials science at Duke University, who was not part of the research. “The team’s accomplishment will leave a significant legacy.”

The technology has been licensed by U-M startup h-Bar Instruments LLC. Hovden and the University of Michigan have a vested financial interest in h-Bar Instruments.

Further financial backing was provided by the Rowland Institute at Harvard University.

The device was constructed and developed at the Michigan Center for Materials Characterization, the ME undergraduate machine shop, and the Wilson Student Team Project Center.

“`