Charged membranes assist in surpassing the existing salinity threshold, facilitating the crystallization of ocean salts and extraction of essential minerals from desalination byproducts

Desalination facilities, an essential and expanding resource of freshwater in arid areas, could yield less detrimental waste by utilizing electricity and innovative membranes developed at the University of Michigan.

The membranes have the potential to assist desalination facilities in reducing or entirely eliminating the brine waste generated as a secondary product of converting seawater into potable water. Presently, liquid brine waste is contained in ponds until the water evaporates, leaving solid salt or highly concentrated brine for additional processing. However, brine requires considerable time to evaporate, leading to significant possibilities to contaminate groundwater.

Space constraints also present a challenge. For each liter of drinking water produced in a typical desalination plant, 1.5 liters of brine are generated. A UN report indicates that over 37 billion gallons of brine waste are produced worldwide daily. When there is insufficient space for evaporation ponds, desalination plants are forced to inject the brine underground or release it into the ocean. Increasing salt concentrations near desalination plants can adversely affect marine ecosystems.

“There’s a significant drive in the desalination sector for improved solutions,” stated Jovan Kamcev, U-M assistant professor of chemical engineering and the lead author of the research published today in Nature Chemical Engineering. “Our innovation could assist desalination facilities in becoming more eco-friendly by diminishing waste while consuming less energy.”

To eradicate brine waste, desalination engineers aim to concentrate the salt so that it can be readily crystallized in industrial vessels rather than in ponds that can cover over a hundred acres. The separated water could be utilized for drinking or agricultural purposes, while the solid salt could be harvested for valuable applications. Seawater is not only composed of sodium chloride—or table salt—but also contains precious metals like lithium for batteries, magnesium for lightweight alloys, and potassium for fertilizers.

Desalination facilities can concentrate brines by heating and evaporating the water, which is very energy-consuming, or through reverse osmosis, which is effective only at relatively low salinities. Electrodialysis presents a promising alternative because it operates efficiently at high salt concentrations and requires comparatively less energy. This method utilizes electricity to concentrate salt, which exists in water in the form of charged atoms and molecules known as ions.

This is how the mechanism functions: water flows through numerous channels separated by membranes, each with an opposite electrical charge compared to its neighboring membranes. The entire flow is bordered by a pair of electrodes. Positive salt ions gravitate towards the negatively charged electrode, being obstructed by a positively charged membrane. Conversely, negative ions move towards the positive electrode and are halted by a negative membrane. This configuration creates two types of channels—one from which both positive and negative ions exit, and another where the ions enter, resulting in streams of purified water and concentrated brine.

However, electrodialysis also has its salinity constraints. As salt concentrations increase, ions begin to seep through the electrodialysis membranes. While there are leak-resistant membranes available, they often transport ions at a slow rate, making the energy demands impractical for brines with salinity exceeding six times that of typical seawater.

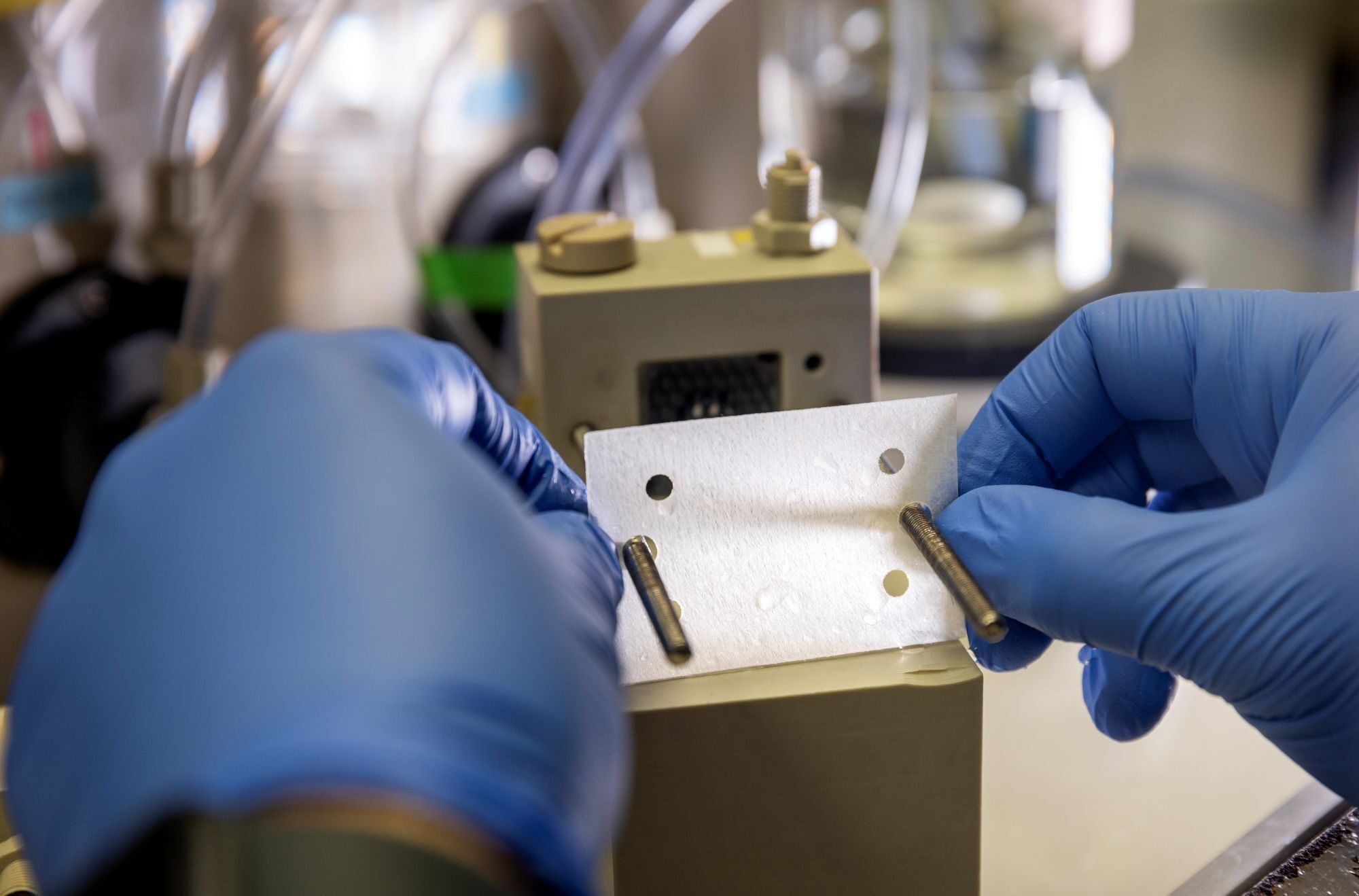

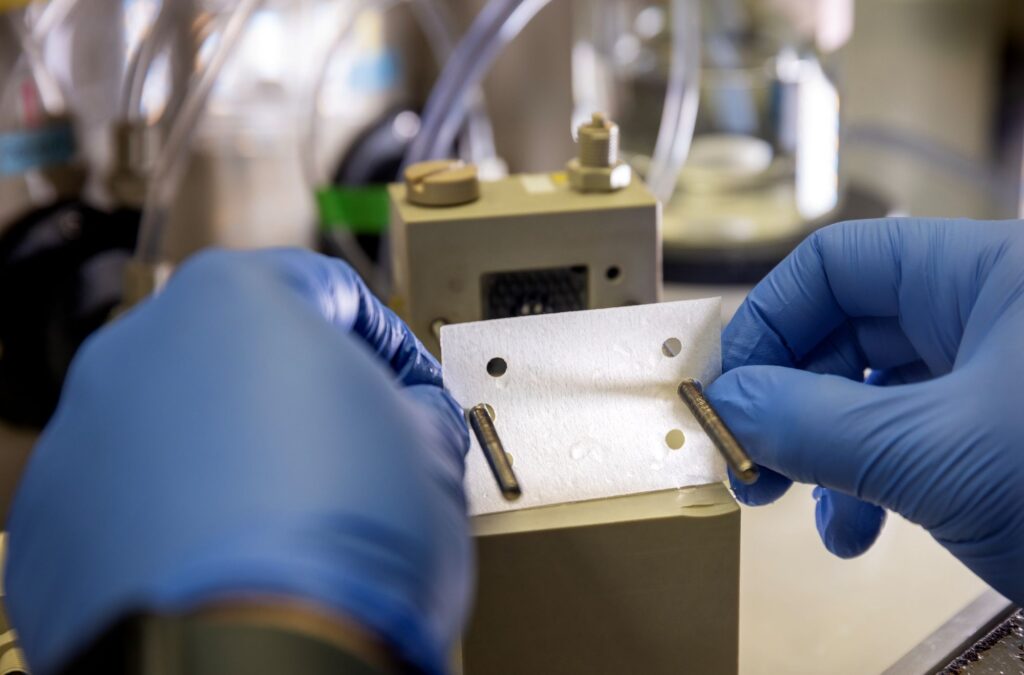

The researchers have addressed this limitation by incorporating an unprecedented number of charged molecules into the membrane, enhancing their ion-repelling capabilities and conductivity—allowing them to transport greater quantities of salt with minimal energy consumption. Through their specialized chemistry, the researchers can manufacture membranes that demonstrate conductivity ten times greater than relatively…

leak-resistant membranes currently available on the market.

The high density of charge typically draws numerous water molecules, which restricts the amount of charge that can be accommodated in traditional electrodialysis membranes. These membranes expand as they take in water, thereby diluting the charge. However, the newly developed membranes feature carbon connectors that inhibit swelling by securing the charged molecules together.

The degree of limitation can be adjusted to manage the permeability and conductivity of the membranes. Allowing a certain degree of permeability can enhance conductivity beyond what is currently offered in the market. The researchers are optimistic that the adjustability of the membrane will facilitate its adoption.

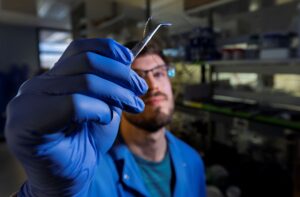

“Not every membrane is suitable for all applications, but our research showcases a wide array of options,” stated David Kitto, a postdoctoral fellow in chemical engineering and the primary author of the study. “Water is an incredibly vital resource, so it would be fantastic to contribute towards making desalination a viable solution to our worldwide water shortage.”

The research was supported by the U.S. Department of Energy and utilized NSF-funded X-ray facilities at the University of Pennsylvania Materials Research Science and Engineering Center.

The team has applied for patent protection with the help of U-M Innovation Partnerships.