“`html

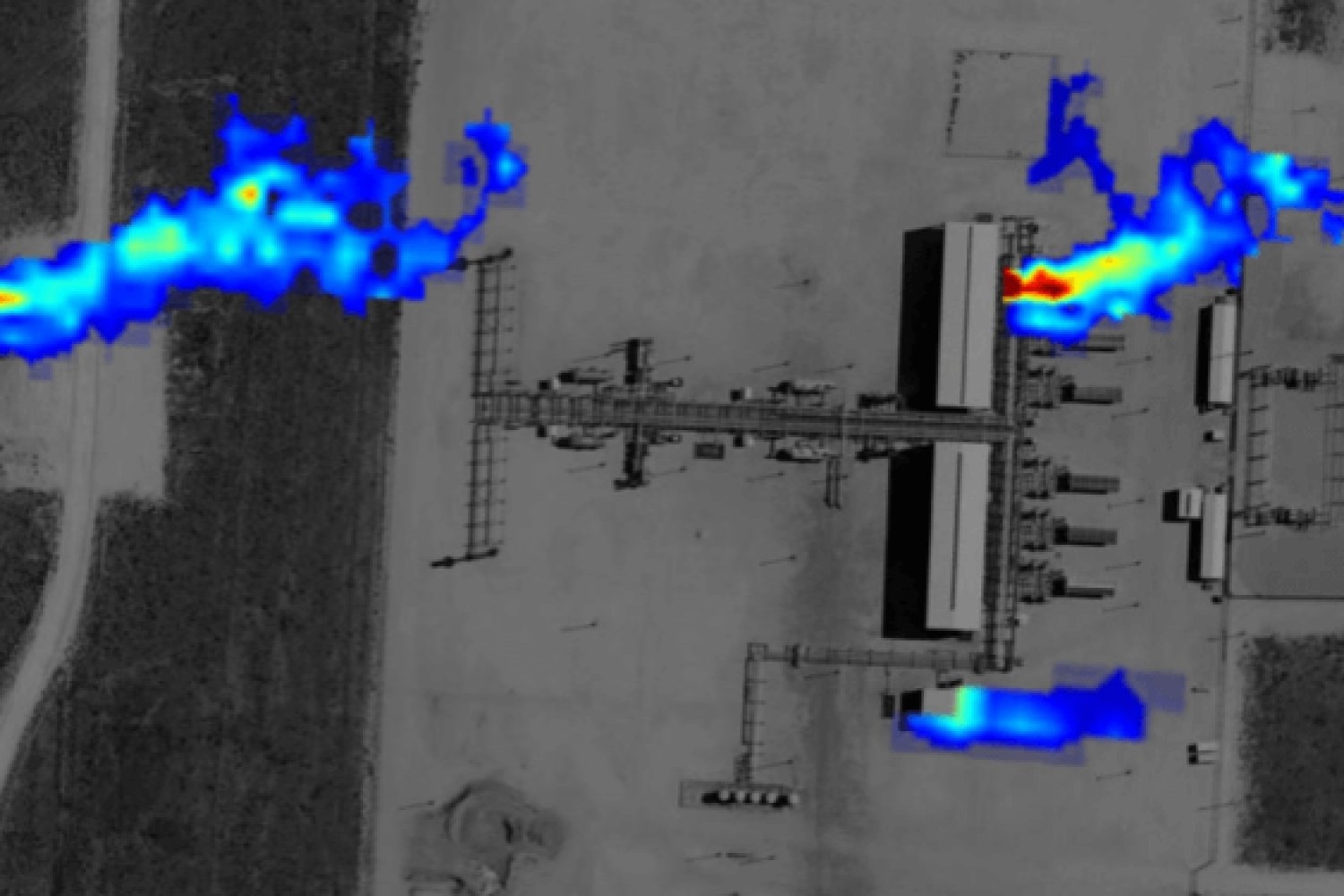

Annually, the U.S. energy sector forfeits an estimated 3 percent of its natural gas output, amounting to $1 billion in earnings, due to faulty infrastructure. Dispersing imperceptibly into the atmosphere, these methane gas emissions can now be observed, photographed, and quantified using specialized lidar mounted on small aircraft.

This lidar originates from Bridger Photonics, a prominent methane-detection firm located in Bozeman, Montana. The MIT Lincoln Laboratory developed the lidar’s optical-power amplifier, a vital element of the system, by enhancing its existing slab-coupled optical waveguide amplifier (SCOWA) technology. The methane-sensing lidar is 10 to 50 times more proficient than rival airborne remote sensors available in the marketplace.

“This drone-compatible sensor for visualizing methane exemplifies Lincoln Laboratory technology in action, coupled with a significant commercial application,” states Paul Juodawlkis, who initiated the SCOWA technology alongside Jason Plant in the Advanced Technology Division and partnered with Bridger Photonics to facilitate its commercial usage.

Currently, the product is being widely embraced, including by nine of the top 10 natural gas producers in the United States. “Maintaining gas within the pipeline benefits everyone — it assists companies in marketing the gas, enhances safety, and conserves the environment,” remarks Pete Roos, founder and chief innovation officer at Bridger. “The challenge with methane is its invisibility. We addressed a fundamental issue with Lincoln Laboratory.”

A laser source “miracle”

In 2014, the Advanced Research Projects Agency-Energy (ARPA-E) was pursuing an economical and exact method to identify methane leaks. Highly combustible and a significant pollutant, methane gas (the main ingredient of natural gas) traverses the nation through a vast and complex pipeline network. Bridger proposed a research initiative in response to ARPA-E’s request and secured funding to create a small, sensitive aerial lidar.

Aerial lidar casts laser light to the ground and assesses the light that bounces back to the sensor. This type of lidar is commonly utilized for generating detailed topographical maps. Bridger’s concept was to integrate topographical mapping with gas measurements. Methane absorbs light at the infrared wavelength of 1.65 microns. Employing a laser at this wavelength could allow a lidar to detect the invisible gas plumes and assess leak rates.

“This laser source was one of the most challenging components to perfect. It’s an essential element,” Roos states. His team required a laser source with specific traits to emit strongly enough at a wavelength of 1.65 microns from effective altitudes. Roos recalled the ARPA-E program manager mentioning that they needed a “miracle” to achieve it.

Through shared connections, Bridger was referred to a Lincoln Laboratory technology for optically amplifying laser signals: the SCOWA. When Bridger reached out to Juodawlkis and Plant, they had been exploring SCOWAs for ten years. Even though they had never examined SCOWAs at 1.65 microns, they believed that the core technology could adapt to that wavelength. Lincoln Laboratory secured ARPA-E funding to develop 1.65-micron SCOWAs and deliver prototype units to Bridger for integration into their gas-mapping lidar systems.

“That was the miracle we required,” Roos states.

A history of laser innovation

Lincoln Laboratory has been a pioneer in semiconductor laser and optical emitter technology for years. In 1962, the laboratory was among the first to demonstrate the diode laser, which is currently the most widely utilized laser worldwide. Numerous spinout companies, like Lasertron and TeraDiode, have commercialized advancements stemming from the laboratory’s laser research, including those for fiber-optic telecommunications and metal-cutting applications.

In the early 2000s, Juodawlkis, Plant, and their colleagues at the laboratory identified the demand for a stable, powerful, and bright single-mode semiconductor optical amplifier, capable of boosting lidar and optical communications. They developed the SCOWA (slab-coupled optical waveguide amplifier) notion by extending previous work on slab-coupled optical waveguide lasers (SCOWLs). The initial SCOWA received backing under the laboratory’s internal technology investment portfolio, a fund of R&D financing supplied by the undersecretary of defense for research and engineering to initiate new technological concepts. These ideas often evolve into sponsored programs or result in commercialized technology.

“Soon, we produced a semiconductor optical amplifier that was 10 times superior to anything that had been previously showcased,” Plant states. Like other semiconductor optical amplifiers, the SCOWA directs laser light through semiconductor material. This process amplifies optical power as the laser light interacts with electrons, prompting them to emit photons at the same wavelength as the input laser. The SCOWA’s distinct light-guiding design allows it to achieve significantly higher output powers, producing a potent and efficient beam. They demonstrated SCOWAs at various wavelengths and applied the technology to projects for the Department of Defense.

When Bridger Photonics approached Lincoln Laboratory, the most significant application of the device emerged. Through an iterative process funded by ARPA-E and a Cooperative Research and Development Agreement (CRADA), the team augmented Bridger’s laser power by over tenfold. This power enhancement permitted them to expand the lidar’s range to altitudes exceeding 1,000 feet.

“Lincoln Laboratory possessed the expertise about what occurs within the optical amplifier — they could take our input, adjust the formula, and create a device that functioned exceptionally well for us,” Roos states.

The Gas Mapping Lidar was commercially launched in 2019. That same year, the product earned an R&D 100 Award, acknowledging it as a groundbreaking advancement in the industry.

A technology transfer takes flight

Currently, the United States stands as the world’s largest natural gas provider, fostering growth in the methane-detection market. Bridger Photonics employs its Gas Mapping Lidar for clients nationwide, affixing the sensor to aircraft and drones while identifying leaks throughout the entire supply chain, from where gas is sourced, transported across the nation, and delivered to businesses and residences. Customers acquire the information from these scans to effectively locate and rectify leaks in their gas infrastructure. In January 2025, the Environmental Protection Agency granted regulatory approval for the technology.

As per Bruce Niemeyer, president of Chevron’s shale and tight operations, the lidar capability has proven to be transformative: “Our objective is straightforward — keep methane within the pipe. This technology assists us in ensuring we are achieving that … It can detect leaks that are 10 times smaller than what other commercial providers can identify.”

At Lincoln Laboratory, researchers continue to innovate new devices in the interest of national welfare. The SCOWA is one of numerous technologies in the arsenal of the laboratory’s Microsystems Prototyping Foundry, which will soon expand to include a new Compound Semiconductor Laboratory – Microsystem Integration Facility. Government, industry, and academia can utilize these facilities through government-financed initiatives, CRADAs, testing agreements, and other methods.

At the request of the U.S. government, the laboratory is also searching for industry transfer partners for a technology that combines SCOWA with a photonic integrated circuit platform. Such a platform could propel advancements in quantum computing and sensing, among other applications.

“Lincoln Laboratory serves as a national asset for semiconductor optical emitter technology,” Juodawlkis asserts.

“`