“`html

Society has long faced challenges with plastic pollution stemming from petroleum, and the growing awareness of the harmful impacts of microplastics on food and water sources intensifies the issue.

In reaction, scientists have been crafting biodegradable alternatives to conventional plastics, commonly referred to as “bioplastics.” Nevertheless, existing bioplastics encounter obstacles: the current types are less robust than their petrochemical counterparts and can only decompose in a high-temperature composting environment.

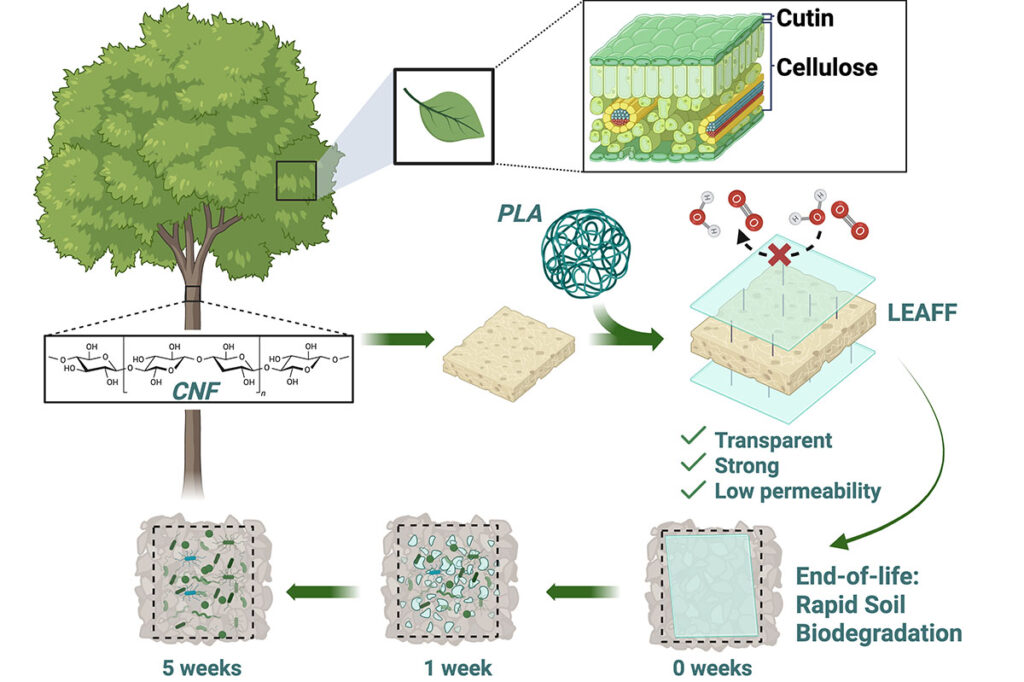

Introducing researchers from Washington University in St. Louis, who have addressed both issues by drawing inspiration from the unassuming leaf. Long before the advent of plastic, people used leaves to wrap food, which readily decomposes due to its cellulose-rich cell wall structure. The chemical engineers at WashU opted to integrate cellulose nanofibers into the bioplastic design.

“We developed a multilayered architecture where cellulose is situated in the center, with bioplastics on either side,” stated Joshua Yuan, the Lucy and Stanley Lopata Professor and chair of energy, environmental, and chemical engineering at the McKelvey School of Engineering. Yuan also serves as the director of the National Science Foundation-supported Carbon Utilization Redesign for Biomanufacturing (CURB) Engineering Research Center. “This design results in a material that is extremely durable and multifunctional,” he remarked.

The innovation was born from working with two of the leading production bioplastics on the market today. In a study released earlier this year in Green Chemistry, Yuan and his team utilized a variation of their cellulose nanofiber structure to enhance the strength and biodegradability of polyhydroxybutyrate (PHB), a plastic derived from starch; they further honed their method for polylactic acid (PLA), as explained in a newly published paper in Nature Communications.

The market for plastic packaging is a $23.5 billion sector largely dominated by polyethylene and polypropylene, both made from petroleum and contributing to the generation of harmful microplastics. The researchers’ refined bioplastic, dubbed Layered, Ecological, Advanced, and multi-Functional Film (LEAFF), transformed PLA into a packaging option that biodegrades at room temperature. Furthermore, the framework facilitates other essential properties, such as minimal air or water permeability, aiding in food preservation and presenting a print-friendly surface. This enhances the cost-effectiveness of bioplastics by eliminating the need for separate labels during manufacturing.

“In addition to all of this, the LEAFF’s foundational cellulose architecture endows it with greater tensile strength than even petrochemicals, such as polyethylene and polypropylene,” clarified Puneet Dhatt, a PhD candidate in Yuan’s lab and lead author of the article.

The breakthrough lay in integrating that cellulosic architecture, which WashU’s engineers successfully replicated, utilizing cellulose fibrils embedded within the bioplastics.

“This distinctive biomimetic design allows us to tackle the constraints associated with bioplastic applications and break through that technological barrier, paving the way for broader bioplastic adoption,” Yuan stated.

Ready for a Circular Economy

The United States is in a prime position to lead the bioplastics market and foster a “circular economy,” where waste materials are repurposed and reintegrated into systems rather than contaminating air and water or accumulating in landfills.

Yuan is optimistic about the potential for this technology to scale quickly and is seeking commercial and philanthropic collaborators to assist in bringing these enhanced methodologies to industry. Competitors from Asian and European research institutions are also striving to advance similar technologies. However, U.S. industries hold an edge due to the country’s extensive agricultural network — and WashU is located near the heart of the nation’s agrichemical sector.

“The U.S. excels in agriculture,” Yuan remarked. “We can supply raw materials for bioplastic manufacturing at a more competitive price compared to other regions across the globe.”

The “raw materials” Yuan mentions include chemicals like lactic acid, acetate, or fatty acids such as oleate, which result from corn or starch fermentation processes performed by microbes that act as bioplastic production units.

Pseudomonas putida, for example, is a microbial strain commonly utilized in fermentation industries, including the production of various polyhydroxyalkanoates (PHA), such as PHB.

Researchers at McKelvey Engineering have developed methods to transform different waste materials, including carbon dioxide, lignin, and food scraps, into bioplastics using strains like P. putida. With enhanced bioplastic design, Yuan’s research further completes that cycle, with a version of PHB and PLA that could be manufactured much more efficiently and safely degrades in the environment.

“The United States faces a waste crisis, and implementing a circular reuse approach could significantly contribute to converting that waste into valuable materials,” Yuan stated. “If we can scale up our bioplastic supply chain, it would generate employment opportunities and create new markets,” he said.

Dhatt PS, Hu A, Hu C, Huynh V, Dai SY, Yuan JS, Biomimetic layered, ecological, advanced, multi-functional film for sustainable packaging. Nat Commun 16, 6649 (2025). DOI:

https://doi.org/10.1038/s41467-025-61693-2

This work was funded by NSF EEC 2330245, NSF MCB 2229160, and U.S. Department of Energy BETO (Bioenergy Technologies Office) Projects.

Li J, Liu W, Chang A, Foudeh Z, Yu J, Wei P, Chen K, Hu C, Puneet D, Dai SY, Yuan JS. Integrated design of multifunctional reinforced bioplastics (MReB) to synergistically enhance strength, degradability, and functionality. Green Chemistry, vol 27; issue 18, 15 April 2025. DOI:

https://doi.org/10.1039/d4gc02440k

This research is supported by NSF MCB 2229160, and U.S. Department of Energy BETO (Bioenergy Technologies Office) projects including EE 0007104, DE EE 0008250, and others.

The article Leaf-inspired design brings bioplastics to the big leagues initially appeared on The Source.

“`