Science & Tech

From Capasso lab to your lounge

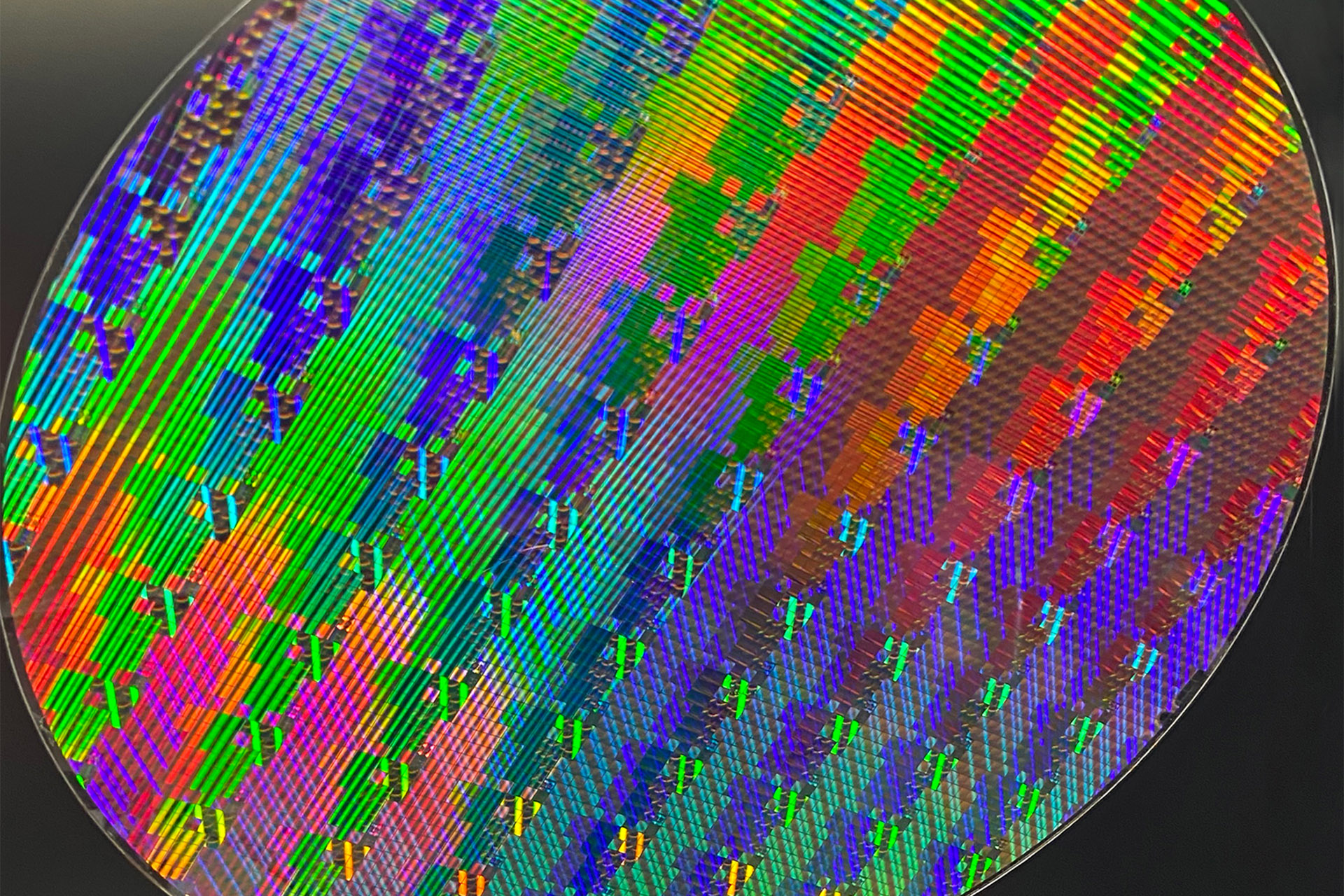

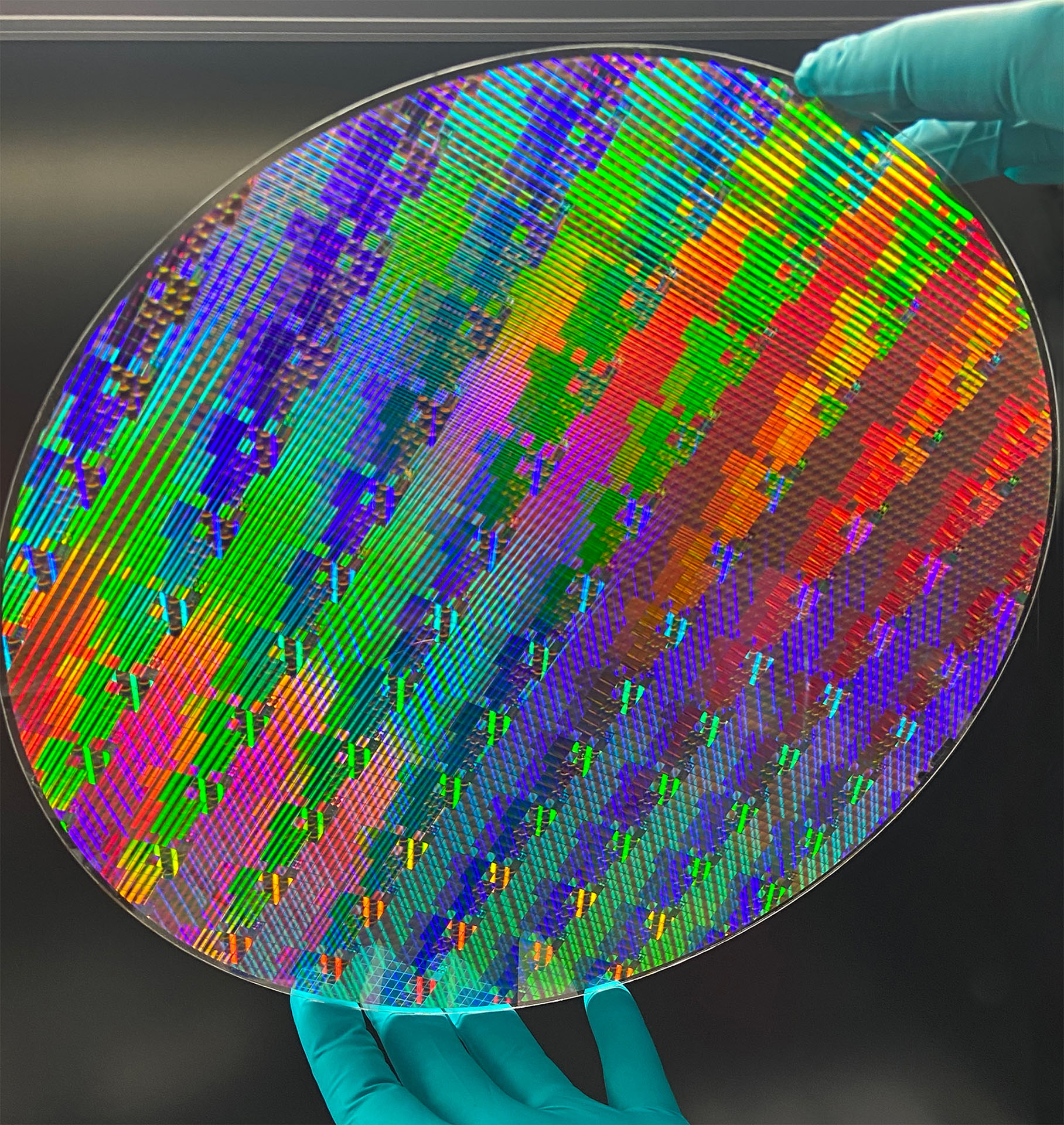

Image credit to Metalenz

Rob Devlin contributed to the development of groundbreaking mini-lens as a graduate student. Now, the startup he heads manufactures millions for consumer gadgets.

During his doctoral tenure at Harvard, Rob Devlin likely crafted 100 iterations of an innovative mini-lens, testing various materials and prototyping fresh designs to bend light akin to a conventional camera solely by utilizing a series of minute pillars on a wafer just a millimeter thick.

This innovative apparatus was intended to be more compact, cost-effective, and capable of being mass-produced — should demand justify it — in semiconductor fabrication plants.

As of now, demand justifies it.

Metalenz, a startup initiated in 2016 with exclusive rights to commercialize the apparatus Devlin assisted in creating in the laboratory of Federico Capasso, the Robert L. Wallace Professor of Applied Physics, reports that around 100 million of its light-focusing metasurfaces have been produced and are incorporated in a variety of consumer electronics.

Metalenz — now led by Devlin as CEO — refrained from disclosing the specific companies utilizing its devices in their offerings, yet at least one report from a firm that conducts teardowns of consumer products, Yole Group, claims that metasurfaces can be found in the iPad, Samsung Galaxy S23 Ultra, and Google’s Pixel 8 Pro.

“It’s astonishing to consider that something which originated at Harvard — during my Ph.D. and with the contributions of all the other team members in the Capasso lab — is now widely used,” Devlin expressed. “Numerous examples exist of university technologies holding significant potential, and having metasurfaces actually integrated into real-world devices at the scale we are now discussing certainly feels remarkable.”

Sam Liss, executive director of strategic partnerships at Harvard’s Office of Technology Development, indicated that Metalenz arose from a cross-disciplinary group, harnessing diverse scientific backgrounds and viewpoints to produce a groundbreaking product.

“[Former University President] Drew Faust once remarked that companies create new products; university research creates new industries.”

Sam Liss, Harvard Office of Technology Development

“It’s truly revolutionizing traditional optics, which have existed for an exceptionally long time, and disrupting that sector,” Liss noted. “That’s what I believe university startups excel at: genuine disruption. [Former University President] Drew Faust famously stated that firms develop new products; university research generates new industries. That sentiment has always resonated with me.”

Capasso’s groundwork on metasurfaces commenced around 2007 or 2008. By the time Devlin joined the lab in 2012, the theoretical aspects were largely established. In a 2011 publication in the journal Science, which has received over 10,000 citations, Capasso and his lab members demonstrated their ability to adjust nanostructures on the metasurface to manipulate light at will.

Shortly thereafter, they unveiled the initial metalens, capable of concentrating light — albeit in an inefficient manner — to a singular point. From that juncture, Devlin applied his knowledge in materials and nanofabrication, collaborating with fellow lab members to enhance the product. Meanwhile, Capasso raised expectations even further: he sought not only a functioning product but one that could be mass-manufactured using pre-existing fabrication techniques to facilitate a swift market entry.

“In record speed, metalenses transitioned from a research prototype in 2016 to the establishment of Metalenz in the same year, followed by mass production for the consumer sector in subsequent years,” Capasso remarked. “Kudos to Rob Devlin for adeptly steering this transition.”

Throughout the journey, researchers recognized the device’s potential to upend the conventional practice of crafting lenses from curved polished glass or plastic. As manufacturers packed smartphones, tablets, and other gadgets with increasingly advanced features, it became evident that the space occupied by oversized lenses posed a constraint on more sophisticated designs.

A significant initial success for Metalenz occurred in 2021 when the startup finalized a contract with STMicroelectronics to integrate its metasurfaces into STMicro’s FlightSense module.

The distance-sensing module employs near-infrared light for three-dimensional sensing, with the metasurface assisting in both emitting light and detecting its reflections. The duration taken for the infrared light to return furnishes essential information for constructing the 3D representation. It finds applications in facial recognition, 3D room mapping, augmented reality, and similar fields.

While these metasurfaces are not primarily employed for visible imagery, they can provide depth information that aids in focusing visual camera lenses.

Rob Devlin.

Photo credit to Metalenz

Metalenz is presently situated in Boston’s North End and has expanded its workforce to approximately 45 employees over the past three years. The company does not require extensive space, as manufacturing is entrusted to large semiconductor foundries, producing over a trillion chips annually for the global technology market.

At Metalenz, Devlin stated, the team concentrates on enhancing the performance of their existing product and developing what they aspire to be the next substantial breakthrough: polar ID.

Polar ID utilizes the polarization of light to provide an extra layer of security for smartphones, resulting in a significant reduction in cost and size.

Devlin explained that a conventional polarization camera spans roughly 100 millimeters in length and ranges from $500 to $1,000 in price. Although smaller versions exist, they are typically found only in premium devices. In contrast, Metalenz’s polarization metasurface measures approximately 5 millimeters in length and is priced around $5, Devlin mentioned, which would facilitate their deployment at minimal cost in a far greater number of devices.

“I can capture a standard image of you. I can determine the spacing between your eyes and the distance from your eyes to your nose and other key landmarks,” Devlin shared. “However, your unique polarization signature means that even if someone produced a flawless 3D replica of you and presented it to the device, the polarization signature of that 3D replica would differ from yours.”

Polarization can be applied in additional domains as well. For instance, the polarization signature of skin affected by cancer differs from that of healthy skin, enabling the detection of harmful growths. It can also be employed for air quality monitoring.

“Numerous exciting developments arise from the capabilities of the metasurface to condense complex modules, scale them down, and empower entirely new functionalities,” Devlin stated.

As is the case with any prosperous product, competitors are striving to catch up, Devlin acknowledged. Metalenz’s approach is to persist in enhancing existing products and innovating new ones that harness the technology to explore new and captivating opportunities.

He also noted among their advantages is their ongoing partnership with Capasso — a co-founder of Metalenz — providing a continuous channel for new advancements emerging from his lab.

“There’s considerable competition, and others are endeavoring to close the gap,” Devlin stated. “Our advantage lies in the initial applications we’ve already rolled out, and we are progressing toward further utilizing even more of the distinctive characteristics of the metasurface.”