Beyond producing devices and gaming components, 3D printing is being applied in the medical field to manufacture prosthetics, dental fixtures, and surgical models. Currently, researchers at Washington University in St. Louis are employing 3D printing to develop bioelectronic frameworks that could enable the generation of new tissues with numerous possible uses.

Alexandra Rutz, an assistant professor of biomedical engineering at the McKelvey School of Engineering, along with Somtochukwu Okafor, a Ph.D. candidate in Rutz’s laboratory, have 3D printed bioelectronic frameworks that possess the characteristics necessary for cells to create new tissue. They disclosed their findings this month in the journal Advanced Materials Technologies.

“Most conventional scaffolds have derived their materials from nature, but in this instance, we are taking that principle and applying it to what we define as functional materials,” Rutz stated. “These are materials specifically engineered to execute a designated purpose, such as electrical conductivity.”

The bioelectronic frameworks that Rutz and Okafor manufacture appear as dark-hued dots roughly 6 millimeters wide — comparable to the diameter of a pencil eraser — and are suspended in water. Okafor has meticulously crafted these miniature frameworks using a polymer known as PEDOT:PSS, which she has transformed into a water-soluble gel utilized as ink.

“When you envision electronics, water isn’t usually part of that picture,” Okafor remarked. “However, that is a benefit of utilizing PEDOT:PSS as the conductive medium. We are fabricating hydrated electronics that preserve their electrical properties within an environment capable of supporting living organisms.”

Okafor, a fifth-year doctoral scholar in biomedical engineering, remarked that even though their team is not the sole group utilizing this method, their approach is distinctive.

“The field of bioelectronics isn’t novel — consider cochlear implants, pacemakers, and smartwatches — but our goal is to interface with biology to make the technology more akin to systems found in nature,” Okafor noted. “We have integrated techniques from 3D printing and tissue engineering with bioelectronics. Each of these processes offers unique advantages, and we are merging them into a unified method.”

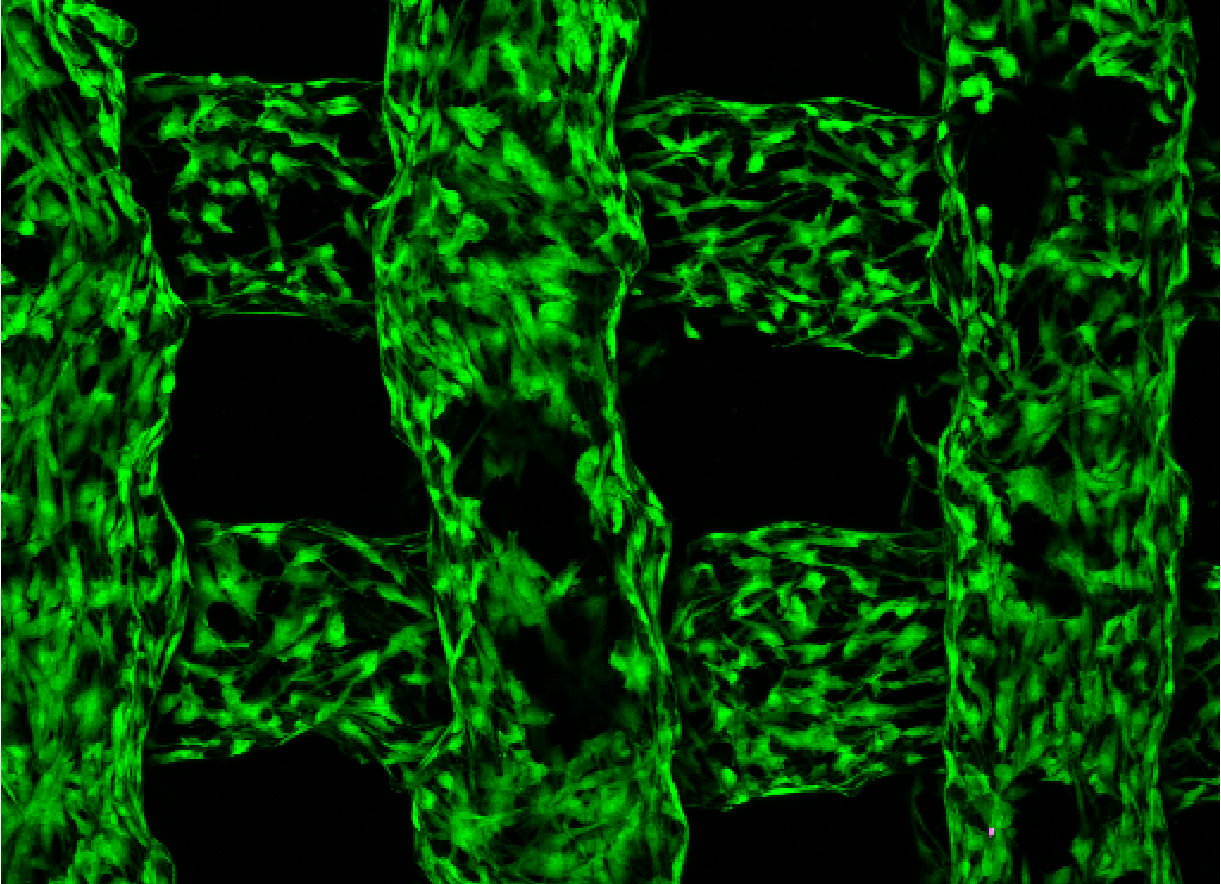

Most conventional materials that are conductive tend to be rigid, which can adversely affect tissue development. Rutz’s lab developed their frameworks from a pliable, conductive hydrogel with pores measuring about 150-300 microns, capable of influencing cellular behavior within the framework, such as attachment to other cells, mobility through the framework, and proliferation. The pores facilitate the formation of a lattice-like structure that ascends to support the cells. Researchers can also modify the orientation of the pores so that the grid aligns diagonally instead of vertically and horizontally.

“The pores must be sufficiently large to grant mobility to the cells, yet small enough so that the cells have a framework to grasp onto and do not fall through,” Okafor explained.

The tissue the team aims to develop could be utilized as either human or plant tissue, rendering it adaptable for various applications.

“We have numerous projects in our lab that are conceptualized for tissues-on-chips technology, which could be employed for drug development, toxicology studies, environmental toxicity assessments, and other projects involving human tissues in a dish,” Rutz articulated.

In collaboration with WashU’s Office of Technology Management, Rutz and Okafor have submitted a patent application for the 3D printing of their bioelectronic frameworks to the U.S. Patent Office.

Okafor SS., Park J, Liu T, Goestenkors AP, Alvarez RM, Semar BA, Yu JS, O’Hare CP, Montgomery SK, Friedman LC, Rutz AL. 3D printed bioelectronic scaffolds with soft tissue-like stiffness. Advanced Materials Technologies, published online Feb. 4, 2025. DOI: https://doi.org/10.1002/admt.202401528

This research was funded by Washington University in St. Louis; National Science Foundation (FR2319060, CMMI 15-48571).

Initially published on the McKelvey Engineering website

The post For success in bioelectronics, build with nature-inspired design was first featured on The Source.