Assembling the lightweight alloy’s intricate mechanical characteristics progresses towards automotive applications to enhance fuel efficiency

In an investigation aimed at promoting lightweight magnesium alloys for more efficient and cost-effective vehicles, researchers from the University of Michigan utilized advanced X-ray technology to obtain the inaugural 3D images of the formation of tiny structures that allow the material to withstand stress without fracturing.

The findings, backed by the U.S. Department of Energy and published in Science, enhance comprehension of the alloy’s intricate response to mechanical stress. Magnesium alloys possess a weight that is 30% lighter than aluminum. Currently, some automotive manufacturers have begun utilizing them in non-load-bearing components, but broader implementation could occur if their performance under stress can be improved.

The crystalline arrangement of each metal—the highly structured, repeating atom configuration—determines its response to stress. Steel and aluminum, the most frequently utilized metals in vehicles, are capable of stretching when pulled in any direction. They accomplish this using what are known as slip systems, where atoms maintain their respective rows but shift within the layers to misalign the columns. This slipping can be likened to a deck of cards on a surface, where the bottom card remains stationary, but a push on one side causes the entire stack to tilt as each card moves a bit farther than the one beneath it.

In contrast, magnesium’s crystalline arrangement permits atoms to slide easily in only a limited number of directions. When pulled in directions where slipping isn’t possible, magnesium alloys develop “deformation twins”—mirror-image segments of the crystal structure—by altering the atom orientation in specific areas. This can be envisioned as an accordion fold in a piece of paper, with the plane emerging from the fold creating the mirror image at an angle.

Deformation twinning enables the material to stretch in multiple directions without fracture, enhancing ductility; however, excessive twinning can lead to defect accumulation that results in crack formation.

“We were taken aback to discover that all three twins formed within triple junctions, where three crystals converge, and defects consistently emerged where a twin interacted with another crystal. This regularity can aid us in understanding twin microstructures to optimize the material’s lifespan,” stated Ashley Bucsek, an assistant professor of mechanical engineering and materials science and engineering at U-M and senior author of the study.

Prior to the experiment, the researchers employed a small-scale CT scanner to chart the orientation of crystal grains within the magnesium alloy sample. From this, they selected a specific grain of interest with optimal orientation for monitoring the twinning process.

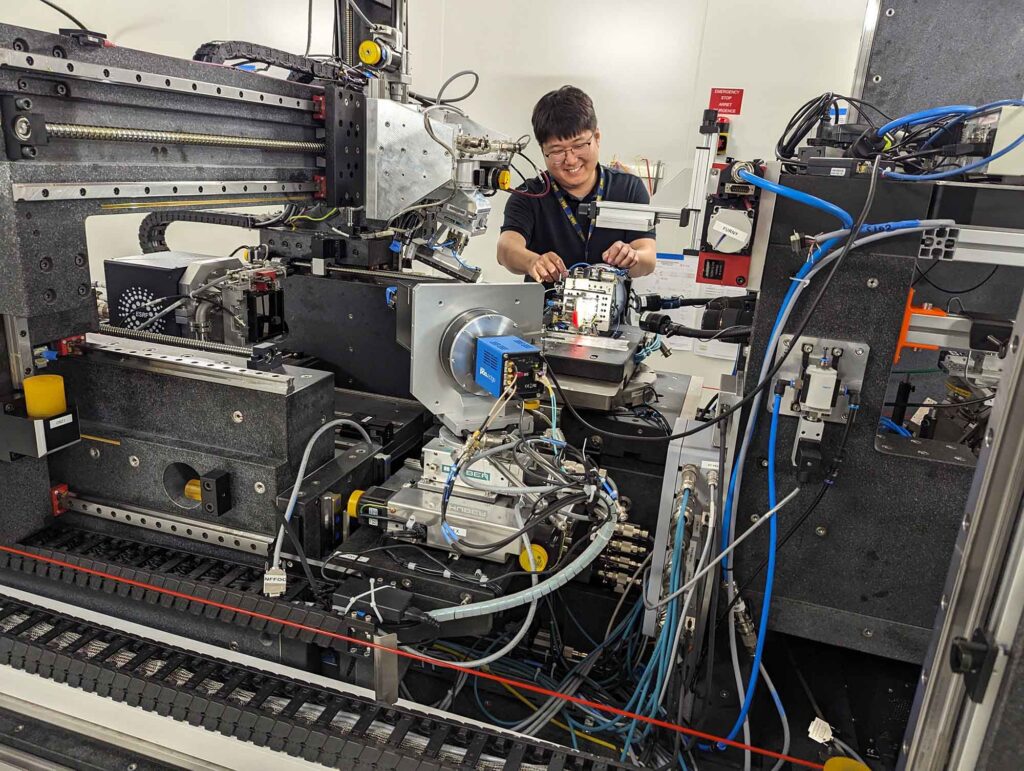

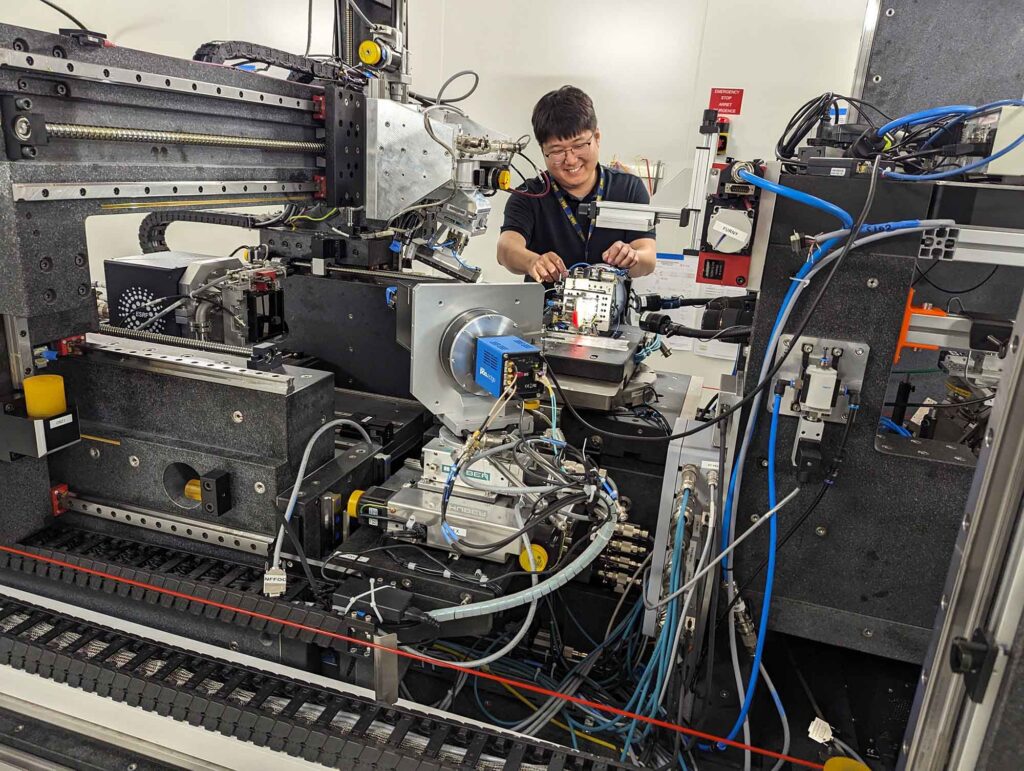

They utilized the European Synchrotron Radiation Facility in France, one of the few global facilities capable of producing sufficiently powerful X-rays to image the selected grain at ultra-high resolution without damaging the sample.

The method, known as dark-field X-ray microscopy, or DXFM for short, operates by accelerating charged particles around the synchrotron and directing the intense X-rays emitted into the alloy. X-rays diffract through the crystal grains at varying angles based on their orientation. The “dark field” technique selectively captures X-rays diffracted at a specific angle—in this instance, the angle related to the previously identified grain of interest—and amplifies the diffracted X-ray image using a series of lenses.

The researchers applied three typical loads encountered in automotive parts that would stretch the alloy—0.6 megapascals (MPa), a unit of tensile strength, 30 MPa, and 45 MPa—capturing images of the sample between each.

“Real-space X-ray images provided us with a front-row observation of twinning as stress was applied. For the first time, we actually witnessed the twin manifest and evolve with our own eyes,” remarked Sangwon Lee, a PhD student in mechanical engineering at U-M and lead author of the study.

The high-resolution visuals are the initial phase toward optimizing the material’s ductility without sacrificing stability. As the next step, the research team aims to capture changes in real-time.

This research is sponsored by the U.S. Department of Energy, Office of Basic Energy Sciences, Division of Materials Science and Engineering (Award DE-SC0008637) as part of the Center for Predictive Integrated Structural Materials Science (PRISMS).

Contributions to the study were made by researchers from the European Synchrotron Radiation Facility, Los Alamos National Laboratory, and National Institute of Standards and Technology.