Researchers at the FAMU-FSU College of Engineering will lead the development of advanced composite materials and manufacturing techniques vital for upcoming space missions, supported by a $5 million grant from NASA.

“Envision having the ability to manufacture sensors, radiation barriers, or even functional tissues during a space expedition,” articulated Professor Subramanian Ramakrishnan from the Department of Chemical and Biomedical Engineering. “This innovation could revolutionize the space exploration framework, enhancing missions’ sustainability and adaptability to unexpected difficulties.”

The NASA funding was awarded to investigators from seven institutions. Florida A&M University will manage the grant on behalf of the FAMU-FSU College of Engineering.

Researchers will collaborate with faculty at Florida State University, including Richard Liang from the FAMU-FSU College of Engineering and Emily Pritchard from the FSU Office of the Provost. They will also engage with Satyanarayan Dev from FAMU and Margaret Samuels from the Goddard Space Flight Center. Each possesses proficiency in creating a system capable of producing exact sensor configurations, integrating sensing materials and electrodes in one step.

Ramakrishnan’s team mainly concentrates on inventing novel materials. They are working on distinctive 2D materials known as MXenes and metallic and semiconducting nanoparticles to create specialized inks for 3D printing in space.

“These advanced inks are utilized to fabricate everything from sensors that identify gases and strain to antennas, radiation protection, and flexible electronic circuits,” remarked Ramakrishnan. “They are particularly significant for 3D-printed materials utilized in space operations.”

In-space manufacturing (ISM) aspires to alter how we generate components for space endeavours. The goal is to empower astronauts to produce what they require in orbit, rendering missions more sustainable and efficient instead of depending on supplies and tools dispatched from Earth.

These exceptional materials exhibit outstanding structural, physical, and chemical properties, making them ideal for a wide range of applications, including energy storage, sensors, optoelectronics, and even biomedical purposes. They are essential for space exploration and possess unique characteristics for specialized materials on our planet.

INNOVATION AND COLLABORATION

Ramakrishnan’s group aims to utilize lunar and Martian soil—commonly referred to as regolith—to develop special inks that can be 3D printed into functional frameworks for future missions to Mars and the Moon.

“This system possesses the essential capability for us to accomplish the fabrication of precise sensor configurations (both sensing materials structures and electrode and connection patterns) in a singular step to guarantee high-quality device integration and on-demand design and manufacturing,” Ramakrishnan explained.

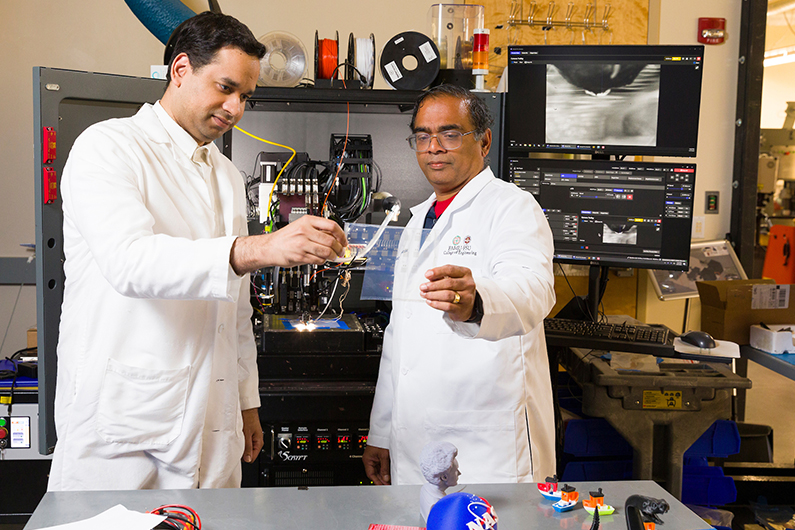

The researchers have introduced a new technique known as electrohydrodynamic (EHD) printing. This approach employs electric fields to accurately print nanoparticles, which can be harnessed to create flexible electronic sensor solutions.

“By combining this printing technique with laser curing, we can swiftly manufacture sensors and accelerate the production process,” stated Ramakrishnan. “This streamlined methodology is vital for future space missions, especially while operating on the International Space Station (ISS).”

NEXT-GENERATION PRINTING

In addition to the NASA funding, Ramakrishnan is spearheading a project supported by a $700,000 grant from the National Science Foundation aimed at facilitating the acquisition of specialized equipment designed for 3D printing on curved surfaces. Florida A&M University has obtained a cutting-edge nScrypt 6-axis 3D printing system capable of creating intricate designs customized to various shapes, particularly for aerospace and medical device applications.

“We are investigating innovative ink formulations and practices,” noted Ramakrishnan. “The equipment is assisting us in developing new and thrilling next-generation sensors for NASA.”

The state-of-the-art printer can accurately dispense materials, allowing researchers to establish complex structures that conform to diverse surfaces.

BIOMATERIALS FOR SPACE

Co-Director and Assistant Professor Jamel Ali from the Department of Chemical and Biomedical Engineering at the college is spearheading research initiatives to comprehend how human cells self-organize in microgravity settings, such as those found on the Moon and Mars. His team is exploring the behavior of 3D-printed tissues in space to enhance therapeutic cell expansion and regenerative medicine. He collaborates with partners, including researchers at the Mayo Clinic in Jacksonville, who work closely with NASA’s Kennedy Space Center on these groundbreaking projects.

His research team works with biomaterials and non-biomaterials to establish guidelines that tackle the unique challenges of 3D printing on curved surfaces. This endeavor could steer innovations that extend well beyond space exploration. They intend to incorporate electrohydrodynamic (EHD) printing methods to develop semiconducting nanomaterials tailored for NASA’s requirements.

IMPACTING THE FUTURE OF MATERIALS SCIENCE

The potential results of the research stretch far beyond NASA missions. The innovative sensors, tissues, and organs crafted could transform areas such as biomedicine and materials science, providing solutions to address urgent health issues and contributing to technological advancements across various sectors.

With NASA’s support and the integration of advanced research practices, the FAMU-FSU College of Engineering is positioned to play a significant role in the future of space exploration. This initiative signifies a crucial advancement in promoting sustainable operations for exploration missions, ensuring we can leverage technology to satisfy our needs in real time.

The article FAMU-FSU College of Engineering professor to study 3D printing for space exploration with $5M NASA grant appeared first on Florida State University News.