In the realm of the animal kingdom, mussels excel at underwater attachment. These marine mollusks congregate on rocks and the hulls of vessels, firmly anchoring themselves against the ocean’s currents due to a viscous plaque they produce through their foot. These persistent adhesive formations have inspired researchers in recent years to create analogous bioinspired, waterproof adhesives.

Recently, engineers from MIT and Freie Universität Berlin have created a novel type of adhesive that merges the waterproof stickiness of mussel plaques with the antimicrobial characteristics of another natural substance: mucus.

Every surface of our bodies that isn’t covered by skin is coated with a protective mucus layer — a slimy web of proteins that serves as a physical shield against bacteria and other pathogenic microorganisms. In their latest study, the engineers fused adhesive, mussel-inspired polymers with protein components derived from mucus, known as mucins, to create a gel that adheres strongly to various surfaces.

The newly developed mucus-based adhesive inhibited bacterial growth while maintaining its adhesive property, even on wet surfaces. The scientists propose that once the adhesive’s characteristics are fine-tuned, it could be applied in liquid form via injection or spray, which would then harden into a sticky gel. This material could potentially be utilized to coat medical implants, for example, to avert infections and bacterial accumulation.

The team’s innovative adhesive formulation could also be modified to include additional natural materials, such as keratin — a fibrous compound found in feathers and hair, featuring certain chemical properties akin to those of mucus.

“The potential uses of our material design strategy will depend on the specific precursor substances,” remarks George Degen, a postdoctoral researcher in MIT’s Department of Mechanical Engineering. “For instance, materials derived from or inspired by mucus could serve as multifunctional biomedical adhesives that also inhibit infections. Alternatively, adapting our method to keratin might lead to the creation of sustainable packaging solutions.”

A publication presenting the team’s findings is featured this week in the Proceedings of the National Academy of Sciences. Degen’s co-authors from MIT consist of Corey Stevens, Gerardo Cárcamo-Oyarce, Jake Song, Katharina Ribbeck, and Gareth McKinley, along with Raju Bej, Peng Tang, and Rainer Haag from Freie Universität Berlin.

A sticky union

Before joining MIT, Degen was a graduate student at the University of California at Santa Barbara, where he contributed to a research team investigating the adhesive mechanisms of mussels.

“Mussels can deposit materials that firmly attach to wet surfaces within seconds to minutes,” Degen explains. “These natural substances outperform currently commercialized adhesives, particularly in adhering to wet and submerged surfaces, which has long been a significant technical hurdle.”

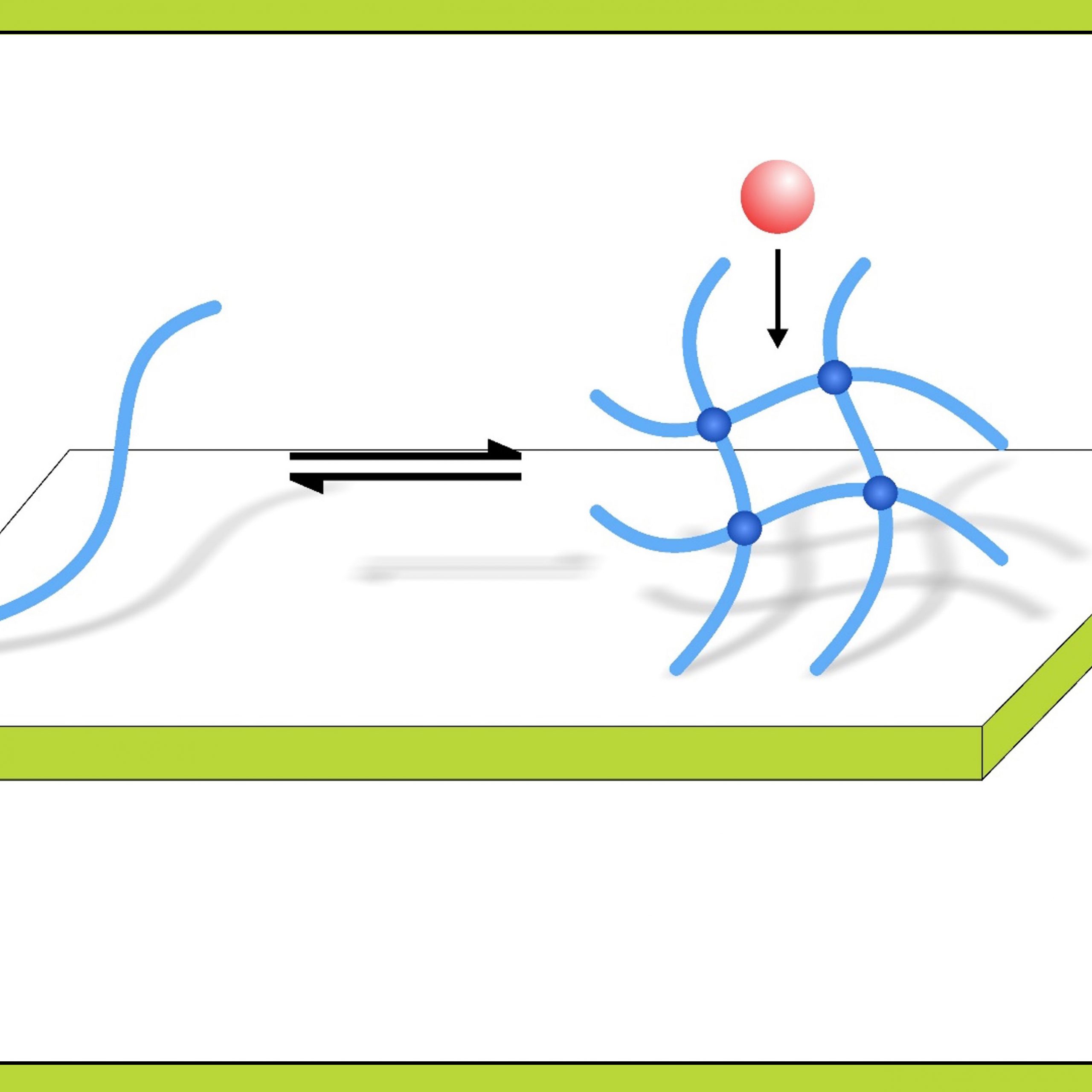

To adhere to a rock or a vessel, mussels release a protein-rich fluid. Chemical bonds, or cross-links, function as connection points between proteins, allowing the secreted fluid to simultaneously solidify into a gel and adhere to a moist surface.

Interestingly, akin cross-linking features are present in mucin — a substantial protein that is the primary non-aqueous component of mucus. Upon arriving at MIT, Degen collaborated with both McKinley, a professor specializing in mechanical engineering and materials science, and Katharina Ribbeck, a professor of biological engineering and an authority on mucus research, to create a cross-linking adhesive combining the sticking properties of mussel plaques with the bacteria-inhibiting features of mucus.

Combining links

The researchers from MIT partnered with Haag and his team in Berlin, who are experts in synthesizing bioinspired materials. Haag and Ribbeck are part of a collaborative research group focused on developing dynamic hydrogels for biointerfaces. Haag’s team has created mussel-like adhesives and mucus-inspired liquids by generating microscopic, fiber-like polymers that structurally resemble natural mucin proteins.

For their current study, the researchers concentrated on a specific chemical motif present in mussel adhesives: a bond between two chemical groups known as “catechols” and “thiols.” In the mussel’s natural adhesive, these groups coalesce to form catechol–thiol cross-links that bolster the cohesive strength of the plaque. Catechols additionally enhance a mussel’s adhesion by binding to surfaces such as rocks and ship hulls.

Notably, thiol groups are also abundant in mucin proteins. Degen speculated whether mussel-inspired polymers could connect with the thiols in mucin, enabling the mucins to quickly transform from a liquid to a sticky gel.

To investigate this hypothesis, he combined solutions of natural mucin proteins with synthetic, mussel-inspired polymers and monitored how the resultant mixture solidified and bonded to surfaces over time.

“It’s akin to a two-part epoxy. You blend two liquids together, and a chemical reaction starts, causing the liquid to harden while the substance simultaneously bonds to the surface,” Degen explains.

“Depending on the degree of cross-linking, we can regulate the pace at which the liquids gel and adhere,” Haag notes. “We can achieve this all on wet surfaces, at room temperature, and under very mild conditions. This is what makes it particularly unique.”

The team placed a variety of compositions between two surfaces and discovered that the resulting adhesive firmly held the surfaces together, with forces akin to those of commercial medical adhesives employed for tissue bonding. The researchers also evaluated the adhesive’s bacteria-inhibiting properties by applying the gel to glass surfaces and keeping them with bacteria overnight.

“We found that a bare glass surface without our coating developed a thick biofilm, whereas with our coating, biofilms were predominantly prevented,” Degen remarks.

The team asserts that with some adjustments, they can enhance the adhesive’s strength further. Consequently, the material could serve as a robust and protective substitute for existing medical adhesives.

“We are thrilled to have established a biomaterials design framework that provides us with these desirable gelation and adhesion properties, and as a foundation, we’ve showcased several key biomedical applications,” Degen states. “We are now poised to explore various synthetic and natural systems and target diverse applications.”

This research was partially funded by the U.S. National Institutes of Health, the U.S. National Science Foundation, and the U.S. Army Research Office.