The application of terahertz waves, characterized by shorter wavelengths and elevated frequencies compared to radio waves, has the potential to facilitate swifter data communication, more accurate medical imaging, and enhanced-resolution radar systems.

However, effectively producing terahertz waves through a semiconductor chip, which is crucial for integration into electronic gadgets, presents notable challenges.

Many contemporary methods fail to produce waves with sufficient radiating power for practical uses unless bulky and costly silicon lenses are employed. Increased radiating power allows terahertz signals to propagate over greater distances. These lenses, which are often larger than the chip itself, complicate the incorporation of the terahertz source into electronic equipment.

To address these challenges, MIT scientists have crafted a terahertz amplifier-multiplier system that achieves superior radiating power compared to existing technologies without needing silicon lenses.

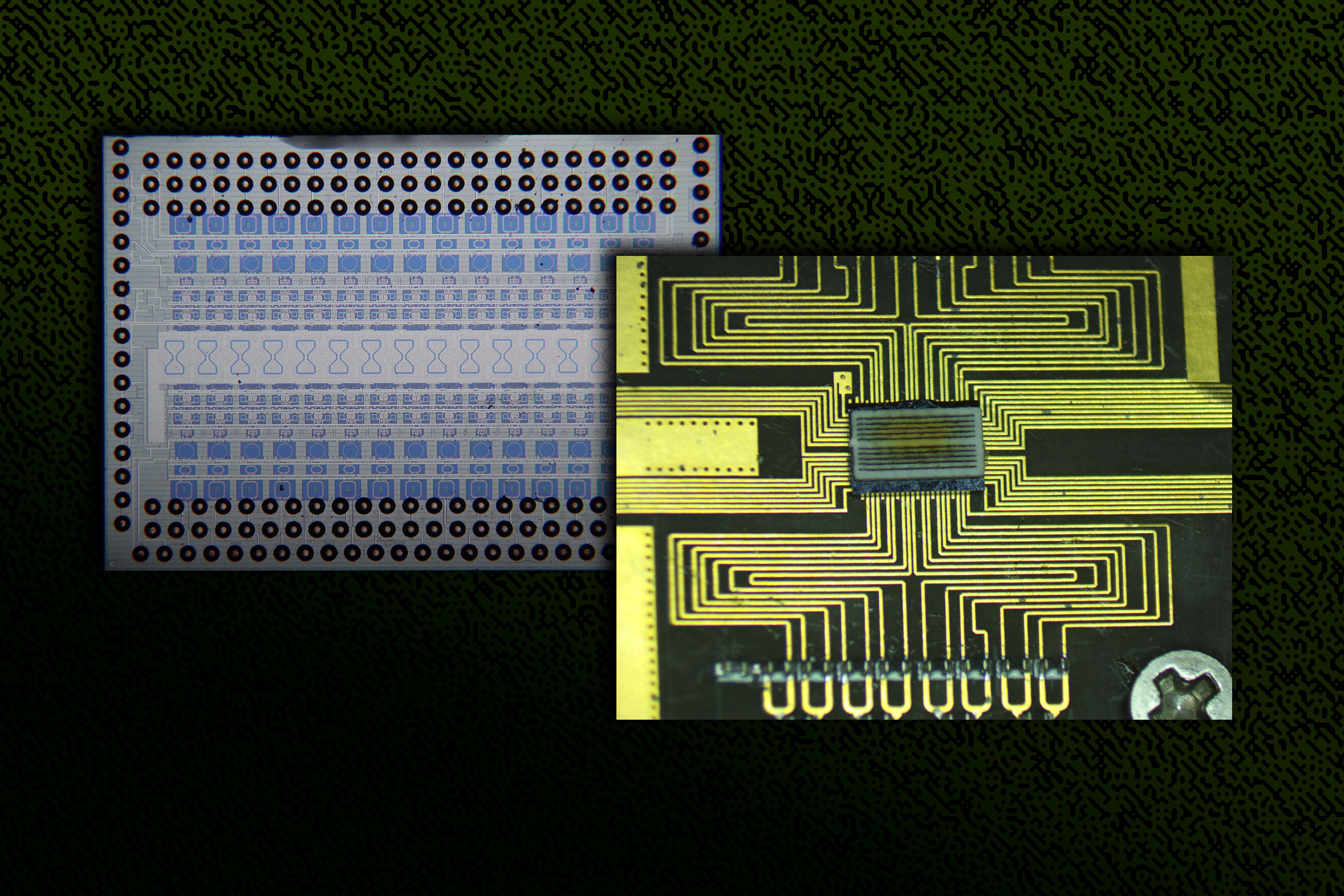

By attaching a thin, patterned layer of material to the rear of the chip and utilizing higher-capacity Intel transistors, the researchers created a more efficient and scalable chip-based terahertz wave generator.

This compact chip could facilitate the creation of terahertz arrays for uses such as enhanced security scanners aimed at detecting concealed objects or environmental monitors for identifying airborne pollutants.

“To fully harness a terahertz wave source, scalability is essential. A terahertz array might comprise hundreds of chips, and there isn’t room for silicon lenses due to the high density at which the chips are integrated. We require a different configuration, and in this instance, we’ve showcased a promising method that supports scalable, low-cost terahertz arrays,” remarks Jinchen Wang, a graduate student within the Department of Electrical Engineering and Computer Science (EECS) and primary author of a paper regarding the terahertz radiator.

Joining him on the paper are EECS graduate students Daniel Sheen and Xibi Chen; Steven F. Nagel, managing director of the T.J. Rodgers RLE Laboratory; and senior author Ruonan Han, an associate professor in EECS, who heads the Terahertz Integrated Electronics Group. The findings will be presented at the IEEE International Solid-State Circuits Conference.

Generating waves

Terahertz waves occupy a position on the electromagnetic spectrum between radio waves and infrared light. Their elevated frequencies allow them to transmit more data per second than radio waves, while they can safely penetrate a broader spectrum of materials than infrared light.

One method of producing terahertz waves involves a CMOS chip-based amplifier-multiplier chain that raises the frequency of radio waves until reaching the terahertz spectrum. To ensure optimal performance, waves traverse the silicon chip and are ultimately emitted out the back into the open atmosphere.

However, a characteristic known as the dielectric constant hinders seamless transmission.

The dielectric constant dictates how electromagnetic waves interact with materials. It influences the extent of radiation that gets absorbed, reflected, or transmitted. Given that the dielectric constant of silicon is significantly greater than that of air, most terahertz waves are reflected at the silicon-air interface rather than being smoothly transmitted out the back.

Since most signal power is diminished at this interface, existing approaches typically employ silicon lenses to amplify the strength of the remaining signal.

The MIT researchers took a different route to tackle this issue.

They drew from an electromechanical principle called matching. Through matching, they aim to equalize the dielectric constants of silicon and air, which will reduce the amount of signal that reflects off the boundary.

This is achieved by adhering a thin layer of material with a dielectric constant between that of silicon and air to the rear of the chip. With this matching layer, the majority of waves will be transmitted out the back instead of being reflected.

A scalable method

They selected a low-cost, commercially sourced substrate material with a dielectric constant closely aligned with their matching requirements. To enhance performance, they utilized a laser cutter to create tiny perforations in the sheet until its dielectric constant was precisely adjusted.

“Since the dielectric constant of air is 1, if you create some subwavelength holes in the sheet, it’s akin to introducing some air, thereby reducing the overall dielectric constant of the matching sheet,” Wang elaborates.

Furthermore, they constructed their chip using specialized transistors from Intel that possess a higher maximum frequency and breakdown voltage than standard CMOS transistors.

“Together, these factors—the more powerful transistors, the dielectric sheet, along with a few other minor innovations—enabled us to surpass several other devices,” he states.

Their chip generated terahertz signals with a peak radiation power of 11.1 decibel-milliwatts, the most efficient among cutting-edge techniques to date. Additionally, since the low-cost chip can be produced at scale, it may be more readily integrated into practical electronic devices.

One of the primary challenges in developing a scalable chip was finding a way to manage power and temperature while generating terahertz waves.

“Due to the high frequency and power, many standard approaches for designing a CMOS chip are not applicable here,” Wang points out.

The researchers also needed to devise a technique for applying the matching sheet that could be effectively scaled up for manufacturing purposes.

In the future, they aim to demonstrate this scalability by fabricating a phased array of CMOS terahertz sources, allowing them to direct and focus a powerful terahertz beam using a low-cost, compact device.

This research received partial support from NASA’s Jet Propulsion Laboratory and the Strategic University Research Partnerships Program, as well as the MIT Center for Integrated Circuits and Systems. The chip was fabricated through the Intel University Shuttle Program.