“`html

An uncomplicated and scalable annealing technique enhances the quality of materials utilized in mobile phones, sensors, and energy harvesting devices

Stronger signals for mobile phones, more precise sensors, and cleaner energy could result from a simple addition to the manufacturing approach of specific semiconductor materials, revealed in a recent investigation led by engineering researchers at the University of Michigan.

Semiconductor materials that convert mechanical stress into electricity––referred to as piezoelectricity––are crucial elements in technologies we utilize daily. In mobile phones, these piezoelectric materials filter incoming signals from antennas to minimize unwanted noise. In vehicles, they activate airbags and assess tire pressure.

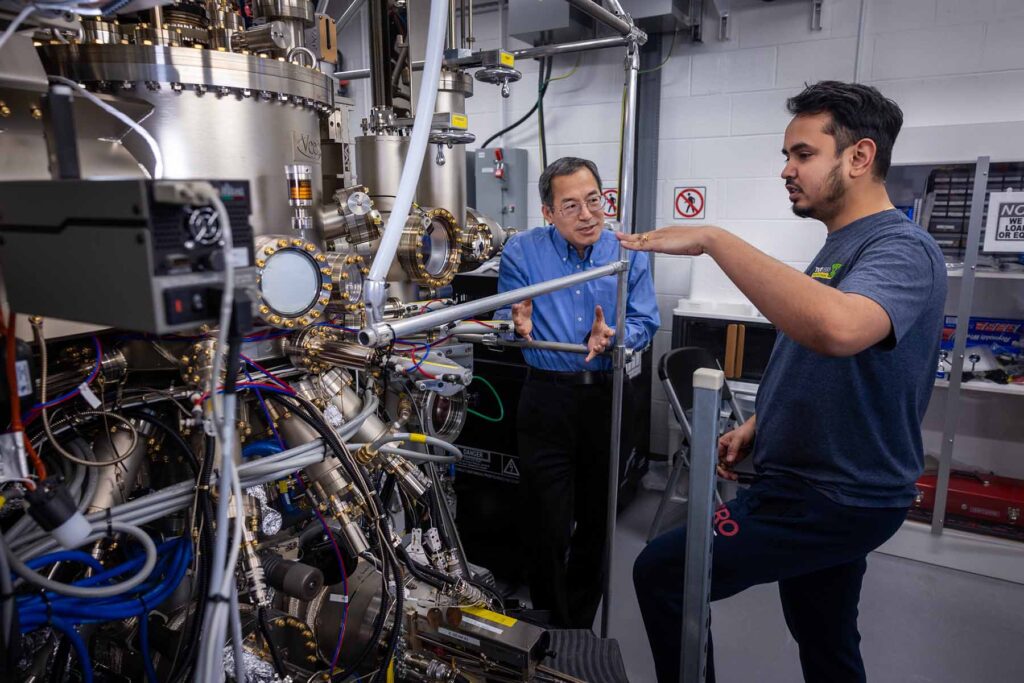

“Our group significantly improved the piezoelectric response of a scandium aluminum nitride film, a promising semiconductor for future microelectronics and photonics, by employing a relatively straightforward annealing technique,” stated Zetian Mi, the Pallab K. Bhattacharya Collegiate Professor of Engineering and corresponding author of the Nature Communications article.

By heating the film to 700 degrees Celsius for two hours in a specialized chamber, Mi’s team enhanced the piezoelectricity of the material to eight times that of the current technology available on the market.

With such an enhancement, piezoelectric materials could revolutionize various sectors, from aviation to healthcare to energy. Increased sensitivity to pressure and vibration could advance sensors that monitor equipment safety and structural integrity, enhance ultrasound techniques, and allow traffic lights to be powered by the vibration from passing trucks.

The researchers also unraveled how the heating procedure enhanced the properties of the material by rectifying imperfections in the thin layers of tiny crystals.

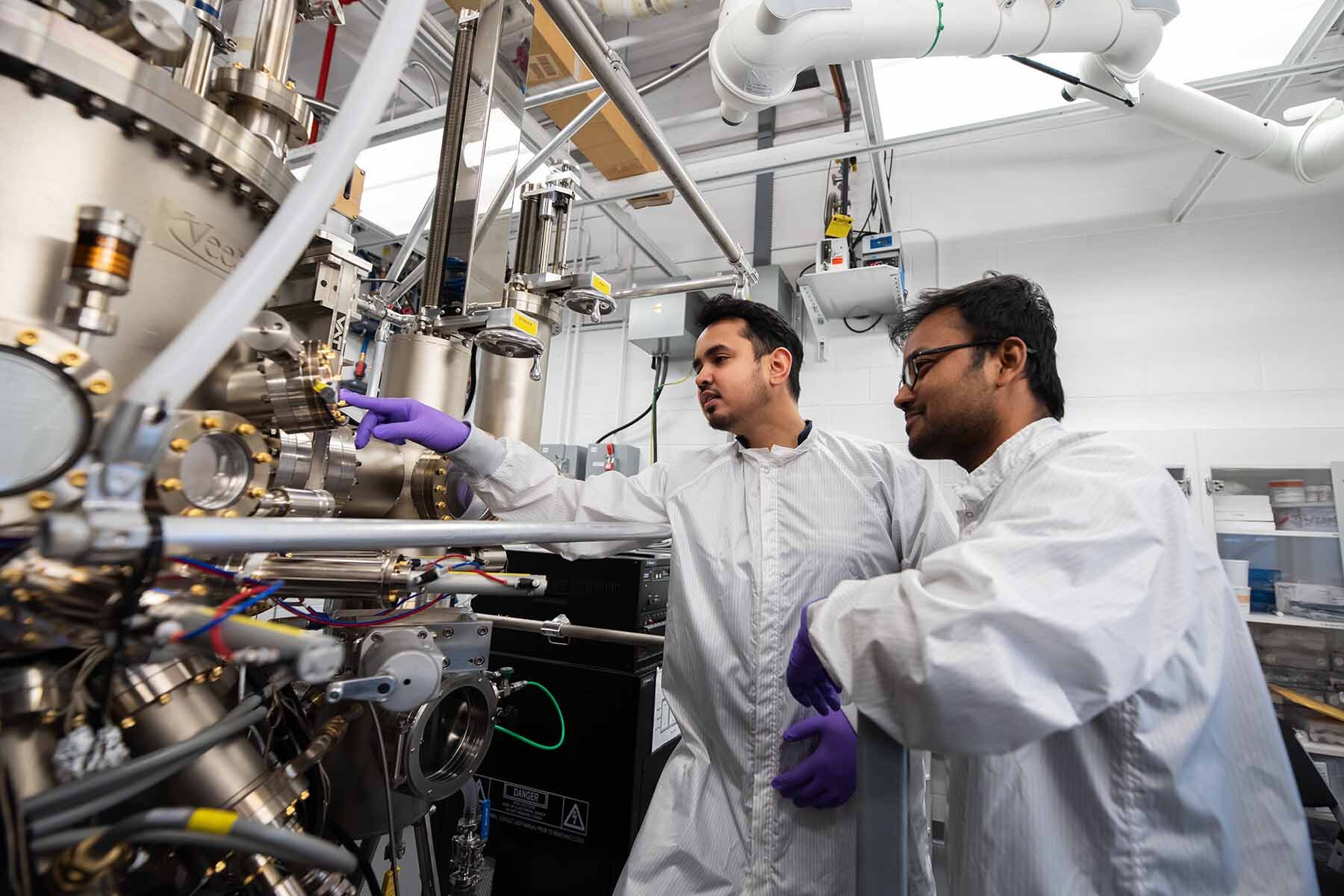

“The piezoelectric response of this material arises from structural ‘grains’ that are aligned in a specific direction. When the films are first grown, these grains may not be perfectly oriented, resulting in some grains not effectively contributing to the overall piezoelectric response,” explained Shubham Mondal, U-M doctoral student in electrical and computer engineering and co-first author of the investigation.

“The annealing technique provides additional energy to the film, facilitating better orientation of the grains. That’s partly why their piezoelectric response is increasing,” noted Md Mehedi Hasan Tanim, U-M doctoral student in electrical and computer engineering and co-first author of the study.

The team intends to apply the annealing technique to scandium aluminum nitride produced using methods that generate higher-quality materials, such as molecular beam epitaxy, to determine if the piezoelectric response can be further improved.

In the meantime, Mi noted, the material and processing required for enhanced piezoelectric performance closely align with current manufacturing standards. The insights gained from the study enable industries to significantly elevate their product capabilities without substantial additional expenses.

The research receives funding from the Defense Advanced Research Projects Agency, as part of a partnership aiming to utilize the improved materials to create a new type of atomic clock, in collaboration with the University of Florida, the U-M College of Engineering, and the Army Research Office.

Collaborators from the University of Florida and Pennsylvania State University also contributed to the study.

The material was processed and analyzed at the Lurie Nanofabrication Facility and the Michigan Center for Materials Characterization.

The team has sought patent protection and is looking for industrial partners to commercialize the technology with the aid of U-M’s Innovation Partnerships.

Mi is also a professor of electrical and computer engineering and materials science and engineering.

“`