“`html

Caltech researchers have devised a technique to fabricate metallic items of a distinctly defined shape and makeup, providing them with unparalleled control over the metallic blends, or alloys, they generate and the improved attributes those creations will exhibit. Interested in a stent that is biocompatible and mechanically sound? Or perhaps sturdy yet lightweight satellite parts that can function in space for many years? The innovative method can inform scientists precisely which metal combinations will produce the optimal outcome. Additionally, it offers a pathway to developing alloys with advantageous characteristics defined by their structural framework, such as unexpectedly strong copper–nickel alloys.

“When observing how metallurgy has been practiced for centuries, in broad terms, the process typically begins with raw ore, which is then thermally and/or chemically altered and purified to yield the desired metal or alloy. Consequently, the mechanical characteristics of the metals produced through these traditional means tend to be constrained,” states Julia R. Greer, the Ruben F. and Donna Mettler Professor of Materials Science, Mechanics, and Medical Engineering at Caltech and executive officer for applied physics and materials science at Caltech. “What we are demonstrating is that it is actually feasible to precisely adjust the chemical composition and the microstructure of metallic materials, significantly improving their mechanical durability.”

Greer and her team elaborate on the new method in a publication released online by the journal Small. The principal author of the article is Thomas T. Tran (PhD ’25), with Rebecca Gallivan (PhD ’23), a former member of the Greer laboratory and now an assistant professor of engineering at Dartmouth College, serving as the secondary author.

The recent technique expands upon earlier research from the Greer lab, where the scientists demonstrated how to utilize a type of 3D printing, or additive manufacturing, to produce intricate microscale metal formations. Previously, the method known as hydrogel-infusion additive manufacturing (HIAM) was applied to painstakingly construct entities from a singular type of metal. In this latest work, Tran has devised a way to infuse multiple metals simultaneously, producing copper–nickel alloys with customized ratios of copper and nickel—variations that matter for material attributes.

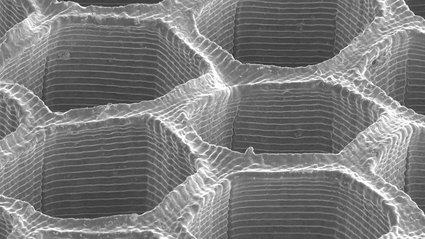

The procedure initiates with the 3D printing of an organic hydrogel substance, accurately placing the polymer resin where needed, layer by layer, to construct a gel-like framework. This framework is subsequently infused with metal ions by applying a liquid solution of metallic salts over the structure. Following this, scientists employ a technique known as calcination to incinerate the material, eradicating all organic components and leaving only the metals behind. As this occurs in the presence of oxygen, what remains is a blend of metal oxides.

In an inventive follow-up step known as reductive annealing, Tran elevates the temperature in a hydrogen atmosphere, allowing most of the oxygen to diffuse out of the solid; it then interacts with hydrogen to create water vapor. This process results in a metallic formation of the desired shape that is an amalgamation of the two included metals.

“The composition can be adjusted in any way you desire, which has not been achievable in conventional metallurgy methods,” Greer elaborates. “One of our colleagues remarked that this work brings metallurgy into the modern era.”

By examining the microstructure, which encompasses the alignment of individual crystal grains and the boundaries between them within the alloys they engineered, and by conducting mechanical evaluations of the materials, the researchers were able to uncover more about the unique alloys created using the new approach.

“This establishes a foundation for considering 3D-printed alloy design in a distinct way compared to other microscale additive manufacturing techniques,” asserts Gallivan. “We observe that the processing conditions yield markedly different microstructures relative to alternative methodologies.”

Utilizing a transmission electron microscope (TEM) at the UC Irvine Materials Research Institute, the Caltech investigators were able to demonstrate that alloys generated through their HIAM technique form more uniformly, resulting in heightened symmetry throughout their crystal structure, as Tran explains. The shape, size, and orientation of metal grains are influenced by the transition between oxide and metal during the reductive annealing process. At increased temperatures, pores are created as water vapor escapes. The growth of metal grains is impeded by these pores and oxides. The latest findings indicate that this growth is affected by the types of oxides present within these 3D-printed metals.

Consequently, the new article reveals that the strength of alloys produced by HIAM is influenced not only by the size of the grains within the metals, as previously assumed, but also by their specific composition. For instance, a Cu12Ni88 alloy containing 12 atoms of copper for every 88 atoms of nickel is nearly four times stronger than a Cu59Ni41 alloy where the ratio of copper to nickel is 59/41.

The TEM evaluations also disclosed that the HIAM process leaves these alloys with minuscule oxide inclusions that enhance the materials’ remarkable strength. “Due to the intricate methods by which metal is formed during this process, we discover nanoscale structures rich with metal–oxide interfaces that bolster the hardening of our alloys by up to a factor of four,” Tran notes.

The publication is titled “Multiscale Microstructural and Mechanical Characterization of Cu–Ni Binary Alloys Reduced During Hydrogel Infusion-Based Additive Manufacturing (HIAM).” The research was funded by the US Department of Energy’s Basic Energy Sciences program and a National Science Foundation graduate fellowship.

“`