A novel approach for enhancing polymer substances may result in more resilient plastics and reduce plastic pollution, as per investigators from MIT and Duke University.

Employing machine learning, the scientists pinpointed crosslinker molecules that can be integrated into polymer substances, enabling them to endure more force prior to rupture. These crosslinkers are part of a category known as mechanophores, which alter their shape or characteristics in reaction to mechanical pressure.

“These molecules can be advantageous in creating polymers that exhibit greater strength when subjected to force. When stress is applied, rather than fracturing, they display increased resilience,” states Heather Kulik, the Lammot du Pont Professor of Chemical Engineering at MIT, who is also a chemistry professor and the principal author of the study.

The crosslinkers identified in this research are iron-based compounds referred to as ferrocenes, which previously had not been widely investigated for their mechanophoric potential. Testing a single mechanophore experimentally can take several weeks, but the team demonstrated that they could utilize a machine-learning model to significantly accelerate this procedure.

MIT postdoc Ilia Kevlishvili is the primary author of the open-access article, featured on Friday in ACS Central Science. Co-authors include Jafer Vakil, a graduate student at Duke; David Kastner and Xiao Huang, both graduate students at MIT; and Stephen Craig, a chemistry professor at Duke.

The weakest link

Mechanophores are substances that react to force in distinct manners, commonly by altering their color, shape, or other attributes. In the recent study, the MIT and Duke researchers aimed to explore whether these molecules could assist in enhancing the durability of polymers against damage.

This research builds on a 2023 investigation led by Craig and Jeremiah Johnson, the A. Thomas Guertin Professor of Chemistry at MIT, along with their colleagues. In that earlier study, the researchers discovered that, unexpectedly, integrating weak crosslinkers into a polymer matrix can actually bolster the overall material’s strength. When materials featuring these weak crosslinkers are elongated to their breaking point, any cracks forming within the material tend to bypass the stronger bonds, navigating through the weaker ones instead. Consequently, the crack is compelled to sever more bonds than it would need to if all the bonds possessed equal strength.

Seeking new methods to take advantage of this phenomenon, Craig and Kulik collaborated to identify mechanophores that could function as weak crosslinkers.

“We had this new mechanistic insight and opportunity, but it came with a significant challenge: Among all possible material compositions, how do we concentrate on those with the most potential?” Craig states. “Full credit goes to Heather and Ilia for recognizing this challenge and formulating an approach to address it.”

Identifying and characterizing mechanophores is a complex endeavor that necessitates either lengthy experiments or resource-intensive simulations of molecular interactions. Most recognized mechanophores are organic substances, such as cyclobutane, which was applied as a crosslinker in the 2023 study.

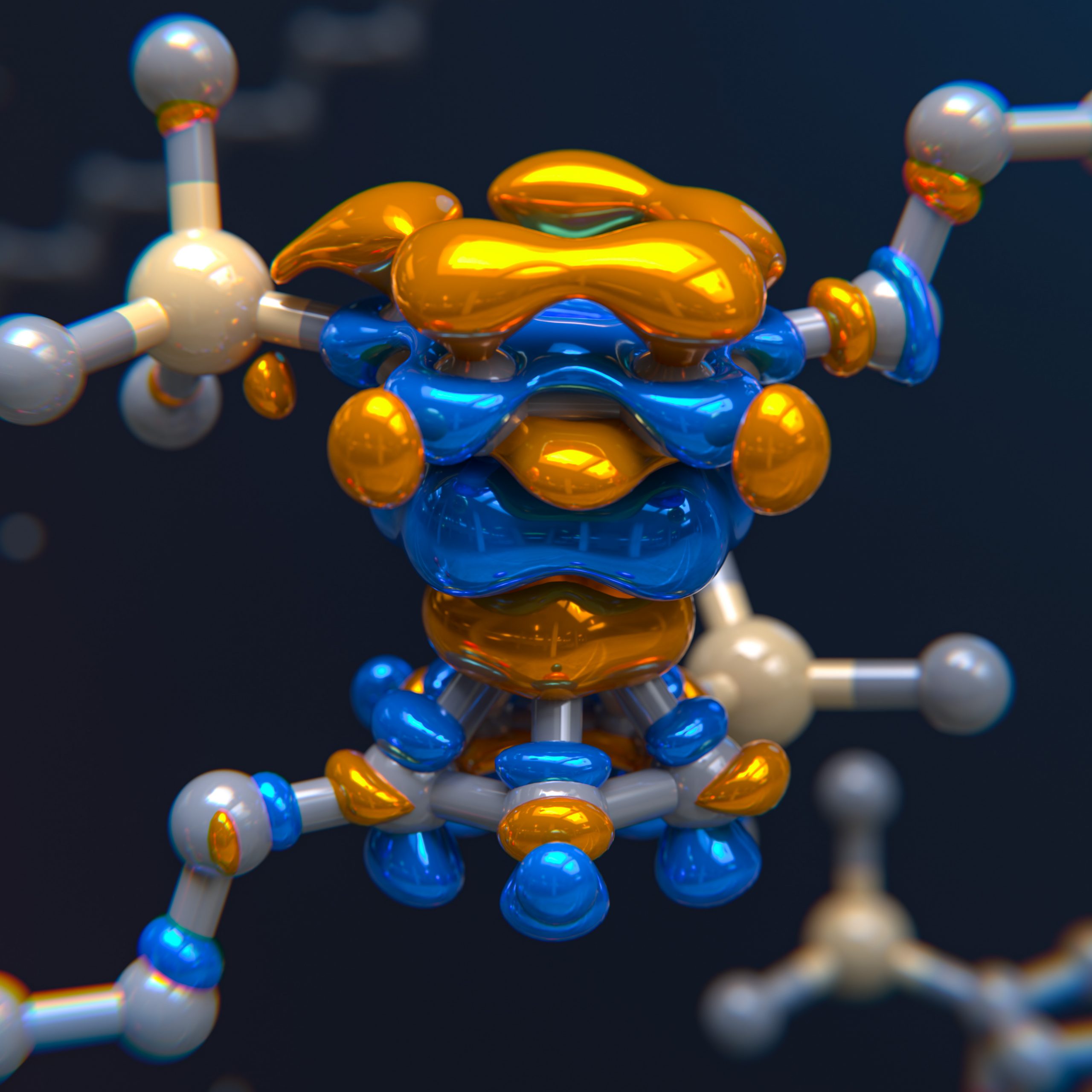

In the present research, the scientists aimed to concentrate on compounds known as ferrocenes, which are thought to have potential as mechanophores. Ferrocenes are organometallic compounds characterized by an iron atom nestled between two carbon-containing rings. Modifying these rings with different chemical groups can alter their chemical and mechanical characteristics.

A variety of ferrocenes are utilized in pharmaceuticals or catalysis, and a limited number are established as effective mechanophores, though the majority have not been scrutinized for this application. Experimental analysis of an individual potential mechanophore can require weeks, while computational simulations are faster but still can take several days. Assessing thousands of candidates using these methods poses a challenging task.

Recognizing that a machine-learning approach could significantly expedite the characterization of these compounds, the MIT and Duke team opted to leverage a neural network to identify ferrocenes that may serve as promising mechanophores.

They began with data from the Cambridge Structural Database, which encapsulates the structures of 5,000 distinct ferrocenes that have been previously synthesized.

“We understood that we didn’t need to be concerned about the question of synthesizability, at least from the mechanophore’s perspective. This enabled us to explore a considerably broad space with substantial chemical diversity, which would also be practically synthesizable,” Kevlishvili remarks.

Initially, the researchers conducted computational simulations for roughly 400 of these compounds, allowing them to determine the force required to separate atoms within each molecule. For this specific application, they sought molecules that would disintegrate swiftly, as these weak links could enhance the tear resistance of polymer materials.

Subsequently, they employed this data, alongside structural information on each compound, to train a machine-learning model. This model was capable of forecasting the force necessary to activate the mechanophore, thereby influencing its tear resistance, for the remaining 4,500 compounds in the database, as well as an extra 7,000 compounds that are similar but feature some atomic rearrangements.

The researchers uncovered two key characteristics that appeared likely to enhance tear resistance. One involved interactions among the chemical groups attached to the ferrocene rings. Furthermore, having large, bulky molecules attached to both rings of the ferrocene increased the likelihood of the molecule breaking apart when forces were applied.

While the first characteristic was not unexpected, the second trait was not something a chemist would have anticipated beforehand and could not have been detected without AI, the researchers assert. “This was genuinely surprising,” Kulik comments.

Tougher plastics

Once the researchers identified around 100 promising candidates, Craig’s lab at Duke produced a polymer substance incorporating one of them, designated m-TMS-Fc. In the resulting material, m-TMS-Fc serves as a crosslinker, linking the polymer strands of polyacrylate, a type of plastic.

By applying force to each polymer until it ruptured, the researchers determined that the weak m-TMS-Fc linker yielded a robust, tear-resistant polymer. This polymer turned out to be approximately four times tougher than polymers produced with standard ferrocene as the crosslinker.

“This has significant ramifications because considering all the plastics we utilize and the accumulation of plastic waste, creating tougher materials could prolong their lifespan. They can be used for an extended duration, which might diminish plastic production in the long term,” Kevlishvili states.

The researchers now aspire to use their machine-learning techniques to identify mechanophores possessing other advantageous characteristics, such as the ability to change color or become catalytically active in response to force. Such materials could function as stress sensors or switchable catalysts, and have potential applications in biomedicine, like drug delivery.

In upcoming studies, the researchers intend to focus on ferrocenes and other metal-based mechanophores that have been synthesized but whose properties remain inadequately understood.

“Transition metal mechanophores are relatively unexplored, and they may pose slightly more challenges to produce,” Kulik remarks. “This computational workflow can be broadly applied to expand the array of mechanophores that researchers have investigated.”

The research was supported by the National Science Foundation Center for the Chemistry of Molecularly Optimized Networks (MONET).