“`html

Imagine if a device could absorb carbon dioxide from the air, process it through various chemical reactions, and ultimately produce industrially beneficial plastic?

“I believe this is something that we, as a community, would find intriguing. Besides being a greenhouse gas, carbon dioxide is a plentiful and affordable feedstock,” states Theo Agapie (PhD ’07), the John Stauffer Professor of Chemistry and the executive officer for chemistry at Caltech. “With our recent advancements, we have made a noteworthy progression toward that goal.”

Publishing in the journal Angewandte Chemie International Edition, Agapie and a team of chemists from Caltech have created a system that utilizes electricity from renewable sources to facilitate the chemical transformation of carbon dioxide (CO2) into molecules, such as ethylene and carbon monoxide, which are useful for producing more intricate compounds. When this conversion is achieved using light as the energy source, without the involvement of plants, it is referred to as artificial photosynthesis. The innovative system channels the ethylene and carbon monoxide generated into a secondary catalytic loop that results in industrially relevant plastics known as polyketones, characterized by their strength, resilience, and thermal stability, making them well-suited for a range of applications including adhesives, automotive components, sporting gear, and industrial piping.

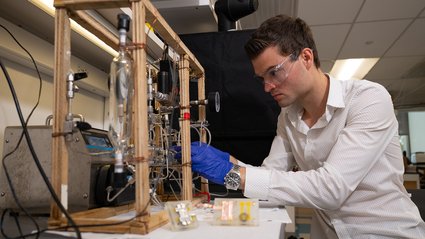

“We have demonstrated that one can utilize CO2 to create a valuable material, without relying on plants as an intermediary,” says lead author Max Zhelyabovskiy (MS ’24), a graduate researcher in Agapie’s lab who was co-mentored on the project by Jonas C. Peters, Caltech’s Bren Professor of Chemistry and director of the Resnick Sustainability Institute.

The Caltech-led group is not the first to develop a system that seeks to combine CO2 reduction with a subsequent chemical reaction to ultimately yield polymers. However, earlier systems have incorporated ethylene sourced from petroleum products, rather than producing it from carbon dioxide and water.

Transforming CO2 all the way into plastic has presented numerous challenges. Among them is the fact that prior electrochemical CO2 reduction systems have generated very low amounts of ethylene and carbon monoxide, the essential reagents for the second step of the conversion to polyketones. In reality, most have resulted in less than 5 percent concentrations of these desired compounds, alongside unwanted chemicals that can adversely affect subsequent processes.

“It has been challenging, at least on the laboratory scale, to acquire high concentration, high purity streams of reagents that can subsequently be transformed into materials like plastic or fuel,” Zhelyabovskiy states. However, the system he contributed to achieves significantly elevated concentrations—11 percent ethylene and 14 percent carbon monoxide.

Nonetheless, that is not the sole challenge. Integrating the two systems—one for CO2 reduction and the other for the catalysis that follows—is not straightforward, Zhelyabovskiy notes. “Most research in the literature concentrates either on the first or the second step, separately and with pure feedstocks. Not both.”

A Two-Step Process

Acknowledging the drastically different environments required for the CO2 reduction and the secondary catalytic step to function efficiently, the Caltech team created a system with two distinct loops for the separate reactions.

In the first loop, the system initiates with gas diffusion electrode cells, hydrophobic polymers coated with a thin layer of copper. The researchers introduce CO2 into a gas cylinder linked to the cells and circulate a potassium bicarbonate electrolyte through the cells, all while applying a voltage to the electrodes. By circulating the gases through this electrochemical setup multiple times, they can generate fairly high concentrations of ethylene and carbon monoxide.

After approximately an hour of accumulating those gases, the scientists then direct the ethylene and carbon monoxide into the second step: a closed reactor where the gases are bubbled through a solution of a palladium catalyst. Similar to a bubbler in an aquarium, this technique enriches the solution in ethylene and carbon monoxide. The catalyst, known as a co-polymerization catalyst, facilitates the efficient creation of a polymer—in this instance, a polyketone—from the two monomers.

A Catalyst that Functions Under Operational Conditions

Usually, catalysts are evaluated under ideal conditions that may not reflect the environments they encounter during electrochemical CO2 reduction. For instance, although water vapor is quite detrimental to many polymerization catalysts, water is a necessary component of CO2 reduction, thus its presence is unavoidable. In their new study, Agapie, Peters, and their colleagues have proven that the palladium catalyst can be utilized even in the presence of contaminants introduced during the CO2 reduction—including not just water vapor but also hydrogen, unreacted CO2, alcohol vapors, and other chemical intermediates.

Zhelyabovskiy mentions that the new system and approach require further improvement. It does not yet produce polyketones with the same molecular weights as those generated through traditional means, for example. Nonetheless, he states, “by illustrating that it is feasible, we could elevate interest in this area, potentially allowing others to build upon this concept.” Agapie emphasizes that for this method to evolve into a sustainable and practical technology, electricity must be sourced from renewable and carbon-neutral origins, and it has to be sufficiently affordable to compete with petroleum sources.

Co-authors of the paper, “Plastic from CO2, Water, and Electricity: Tandem Electrochemical CO2 Reduction and Thermochemical Ethylene-CO Copolymerization,” include Hyuk-Joon Jung and Paula L. Diaconescu of UCLA.

The project was founded on work conducted by the Liquid Sunlight Alliance (LiSA), an energy initiative supported by the U.S. Department of Energy that unites the expertise and efforts of scientists at Caltech, Lawrence Berkeley National Laboratory, the Stanford National Accelerator Laboratory, and the National Renewable Energy Laboratory, along with academic partners from UC Irvine, UC San Diego, and the University of Oregon. Additional sponsorship was provided by the National Science Foundation for the UCLA team.

“`