“`html

Within the biotech and pharmaceutical sectors, ELISA assays deliver essential quality oversight during drug innovation and production. These assays can accurately gauge protein quantities, but they necessitate hours of labor from qualified technicians and specialized apparatus. This renders them excessively costly, elevating drug prices and placing research testing out of reach for numerous entities.

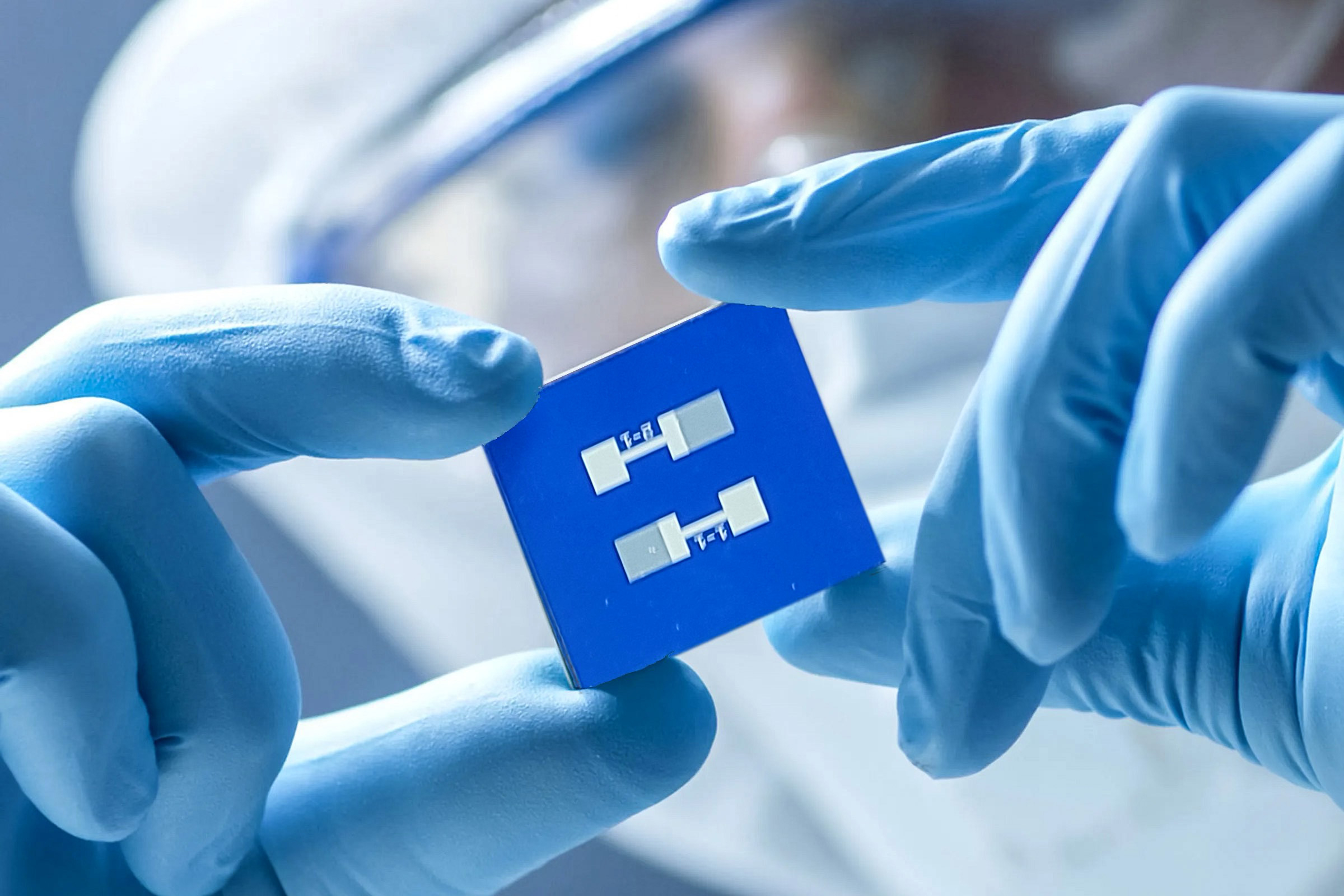

Now the Advanced Silicon Group (ASG), established by Marcie Black ’94, MEng ’95, PhD ’03, and Bill Rever, is commercializing an innovative technology that may significantly reduce the time and expenses linked to protein detection. ASG’s proprietary sensor merges silicon nanowires with antibodies capable of binding various proteins, thus producing a highly sensitive assessment of their concentration in a specific solution.

The assays can assess the concentration of multiple proteins and other molecules simultaneously, with outcomes typically ready in under 15 minutes. Users merely need to place a minute amount of solution on the sensor, wash the sensor, and then insert it into ASG’s portable testing system.

“We’re making it 15 times faster and 15 times cheaper to check for proteins,” Black states. “That pertains to drug development. This could also expedite the drug manufacturing process substantially and make it more economical. It could transform how we produce medications in this nation and globally.”

Since the inception of its sensor, ASG’s team has garnered inquiries from a broad array of individuals eager to utilize them for creating new therapeutics, aiding elite athletes in training, and assessing soil concentration in agriculture, among other uses.

For the moment, though, the small enterprise is concentrating on reducing barriers in healthcare by marketing its affordable sensors to organizations engaged in drug development and manufacturing.

“Currently, funding is a restricting factor in researching and producing new drugs,” clarifies Marissa Gillis, a member of ASG’s team. “Accelerating these processes and reducing costs could exponentially boost the volume of biological testing and product creation. It also makes it more feasible for organizations to develop drugs for rare diseases with smaller markets.”

A family away from home

Black was raised in a small community in Ohio before attending MIT for three degrees in electrical engineering.

“Attending MIT transformed my life,” Black shares. “It broadened my horizons regarding the potentials of utilizing science and engineering to improve the world. Additionally, being surrounded by so many extraordinary individuals taught me to aspire high.”

For her PhD, Black collaborated with the late Institute Professor Mildred Dresselhaus, a renowned physicist and nanotechnology trailblazer, whom Black remembers for her mentorship and kindness as much as her contributions to understanding exotic materials. Black couldn’t always afford to return home for holidays, leading her to spend Thanksgivings with the Dresselhaus family.

“Millie was an incredible individual, and her family was a home away from home for me,” Black recounts. “Millie remained my mentor — and I hear she did this with many students — until the day she passed away.”

In her thesis, Black examined the optical properties of nanowires, which educated her about the nanostructures and optoelectronics she would eventually employ as part of the Advanced Silicon Group.

After graduation, Black worked at the Los Alamos National Laboratory before founding Bandgap Engineering, which developed efficient, inexpensive nanostructured solar cells. That technology was later commercialized by other firms and became the subject of a patent dispute. In 2015, Black established the Advanced Silicon Group to adapt a similar technology for protein detection.

ASG’s sensors integrate established methods for sensitizing silicon to biological molecules, harnessing the photoelectric characteristics of silicon nanowires to electrically detect proteins.

“It’s essentially a solar cell that we modify with an antibody specific to a certain protein,” Black explains. “When the protein approaches, it brings an electrical charge that repels light carriers within the silicon, altering how effectively the electrons and holes can recombine. By monitoring the photocurrent when exposed to a solution, you can determine how much protein has adhered to the surface and consequently the concentration of that protein.”

ASG was welcomed into MIT.nano’s START.nano startup accelerator and MIT’s Office of Corporate Relations Startup Exchange Program shortly after its establishment, granting Black’s team access to state-of-the-art equipment at MIT and connecting her with potential investors and collaborators.

Black has also received extensive support from MIT’s Venture Mentoring Service and collaborated with researchers from MIT’s Microsystems Technology Laboratories (MTL), where she conducted research as a student.

“Even though the company operates out of Lowell, [Massachusetts], I am frequently visiting MIT and receiving assistance from professors and researchers there,” Black remarks.

Biosensing for impact

Through comprehensive dialogues with individuals in the pharmaceutical field, Black recognized the need for a more economical protein measurement solution. During drug innovation and production, protein levels must be evaluated to identify issues such as contamination from host cell proteins, which can be lethal to patients even in trace amounts.

“It can exceed $1 billion to develop a drug,” Black notes. “A significant portion of the procedure involves bioprocessing, and 50 to 80 percent of bioprocessing is allocated to purifying these undesired proteins. This complication results in medications being more expensive and prolonging their time to market.”

ASG has since collaborated with researchers to create tests for biomarkers linked to lung cancer and dormant tuberculosis and has earned multiple grants from the National Science Foundation, the National Institute of Standards and Technology, and the commonwealth of Massachusetts, including funding to develop tests for host cell proteins.

This year, ASG announced a collaboration with Axogen to assist the regenerative nerve repair company in growing nerve tissue.

“There’s considerable interest in applying our sensor for purposes in regenerative medicine,” Black reveals. “Another scenario we foresee is if you’re ill in rural India, and there’s no doctor nearby; you could arrive at a clinic, and nurses could administer this to test for flu, Covid-19, food poisoning, pregnancy, and a dozen other conditions all simultaneously. Results would be available in 15 minutes, allowing you to receive necessary treatment or consult a doctor via teleconference.”

ASG is currently capable of producing approximately 2,000 of its sensors on 8-inch chips per production line in its partner’s semiconductor foundry. As the organization continues to scale production, Black remains optimistic that the sensors will reduce costs at every juncture between drug developers and patients.

“We genuinely aspire to dismantle the barriers to testing so that everyone can access quality healthcare,” Black emphasizes. “Moreover, there are innumerable applications for protein detection. It’s truly where the intersection occurs in biology, agriculture, and diagnostics. We’re eager to collaborate with leaders across all these sectors.”

“`