“`html

Scientists at the FAMU-FSU College of Engineering have developed a liquid hydrogen storage and distribution system aimed at making zero-emission flight a possibility. Their research details a scalable, cohesive system that tackles several engineering obstacles simultaneously by enabling the use of hydrogen as a clean energy source and as a built-in cooling agent for essential power systems within electric aircraft.

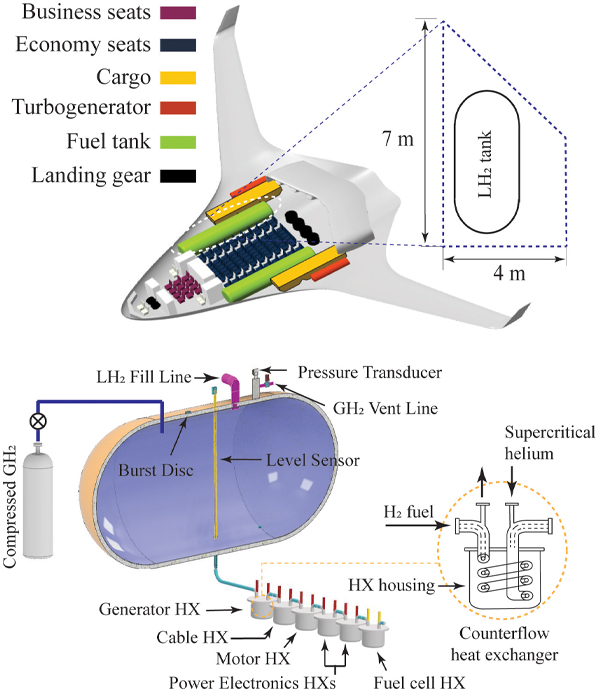

The study, featured in Applied Energy, presents a design customized for a 100-passenger hybrid-electric aircraft drawing energy from both hydrogen fuel cells and hydrogen turbine-driven superconducting generators. It illustrates how liquid hydrogen can be effectively stored, safely transferred, and utilized to cool important onboard systems — all while fulfilling power requirements during different flight stages such as takeoff, cruising, and landing.

“Our aim was to devise a single system that manages multiple essential operations: fuel storage, cooling, and distribution control,” stated Wei Guo, a professor in the Department of Mechanical Engineering and primary author of the study. “This model establishes a basis for practical hydrogen aviation systems.”

WHAT THEY ACCOMPLISHED

Hydrogen is regarded as a viable clean fuel for aviation as it contains more energy per kilogram than conventional jet fuel and generates no carbon emissions. However, it is considerably less dense, requiring it to be stored as a super-cold liquid at –253°C to occupy less size.

To tackle this issue, the team performed extensive system-level optimization to design cryogenic tanks along with their related subsystems. Rather than concentrating solely on the tank, they introduced a new gravimetric index, which refers to the ratio of fuel mass to the entire fuel system. Their index encompasses the mass of hydrogen fuel, tank structure, insulation, heat exchangers, circulation devices, and working fluids.

Through iterative adjustments of critical design aspects, such as vent pressure and heat exchanger sizes, they pinpointed the arrangement that maximizes fuel mass in relation to total system mass. The resulting optimal design reaches a gravimetric index of 0.62, indicating that 62% of the system’s overall weight consists of usable hydrogen fuel, marking a significant advantage over traditional designs.

The system also plays a crucial role in thermal management. Instead of utilizing a separate cooling system, the design directs the extremely cold hydrogen through a chain of heat exchangers that eliminate excess heat from onboard components such as superconducting generators, motors, cables, and power electronics. As hydrogen soaks up this heat, its temperature gradually rises, an essential step since hydrogen needs to be preheated before entering the fuel cells and turbines.

HOW IT FUNCTIONS

Transporting liquid hydrogen throughout the aircraft introduces its own complications. Mechanical pumps contribute additional weight and intricacy and may generate unwanted heat or risk malfunction in cryogenic settings. To prevent these concerns, the team devised a pump-free system that utilizes tank pressure to regulate the flow of hydrogen fuel.

The pressure operates through two methods: injecting hydrogen gas from a standard high-pressure cylinder to boost pressure and venting hydrogen vapor to reduce it. A feedback loop connects pressure sensors to the aircraft’s power demand profile, facilitating real-time adjustments of tank pressure to ensure the appropriate hydrogen flow rate throughout all flight stages. Simulations indicate it can deliver hydrogen at rates up to 0.25 kilograms per second, adequate to satisfy the 16.2-megawatt electrical requirement during takeoff or an emergency go-around.

The heat exchangers are organized in a sequential arrangement. As hydrogen makes its way through the system, it first cools high-efficiency components functioning at cryogenic temperatures, including high-temperature superconducting generators and cables. It then absorbs heat from higher-temperature elements, such as electric motors, motor drivers, and power electronics. Finally, just before reaching the fuel cells, the hydrogen is preheated to align with optimal fuel cell inlet conditions.

This staged thermal integration allows liquid hydrogen to function as both a coolant and a fuel source, boosting system efficiency while simplifying hardware design.

“In the past, experts were uncertain about the effective transport of liquid hydrogen within an aircraft and whether it could also serve to cool the power system components,” Guo stated. “We not only proved that it’s feasible but also highlighted the necessity for a system-level optimization in this type of design.”

FORTHCOMING STEPS AND COLLABORATORS

While this investigation concentrated on design optimization and system simulation, the subsequent phase will entail experimental confirmation. Guo and his team aspire to construct a prototype system and conduct experiments at FSU’s Center for Advanced Power Systems.

This project is a segment of NASA’s Integrated Zero Emission Aviation initiative, which unites institutions across the U.S. to innovate a comprehensive array of clean aviation technologies. Partnering universities comprise Georgia Tech, Illinois Institute of Technology, University of Tennessee, and University at Buffalo. FSU spearheads the effort in hydrogen storage, thermal management, and power system configuration.

At FSU, significant contributors include graduate student Parmit S. Virdi; professors Lance Cooley, Juan Ordóñez, Hui Li, Sastry Pamidi; and other faculty specialists in cryogenics, superconductivity, and power systems.

FINANCING

This initiative was financed by NASA as part of the organization’s University Leadership initiative, which provides an opportunity for U.S. universities to acquire NASA funding and take the lead in developing their own teams and shaping their own research agenda with objectives that support and enhance the agency’s Aeronautics Research Mission Directorate and its Strategic Implementation Plan.

Guo’s research took place at the FSU-based National High Magnetic Field Laboratory, which is funded by the National Science Foundation and the State of Florida.

The post FAMU-FSU researchers create cryogenic hydrogen storage and delivery system for next-generation aircraft appeared first on Florida State University News.

“`