Models created at U-M illustrate how incompatible geometries can result in intriguing complexity and improve material characteristics such as durability and resilience

Anyone who has attempted to tile a floor, create a backsplash, or engage in any arts-and-crafts task likely understands the emotional strain of dealing with pieces whose contours do not align seamlessly.

However, it may be the case that certain organisms actually depend on these mismatches to generate geometric frustrations that give rise to intricate natural formations with exceptional traits, such as protective shells and robust yet adaptable bones.

Researchers at the University of Michigan have now constructed mathematical models that reveal one method through which nature accomplishes this task. These models may, in turn, assist in developing advanced materials for medical instruments, sustainable building, and beyond.

“Frustration—utilizing these mismatched building components—produces fascinating complexity, and this complexity can be advantageous in providing superior material traits,” stated Xiaoming Mao, professor of physics at U-M and senior author of the latest study.

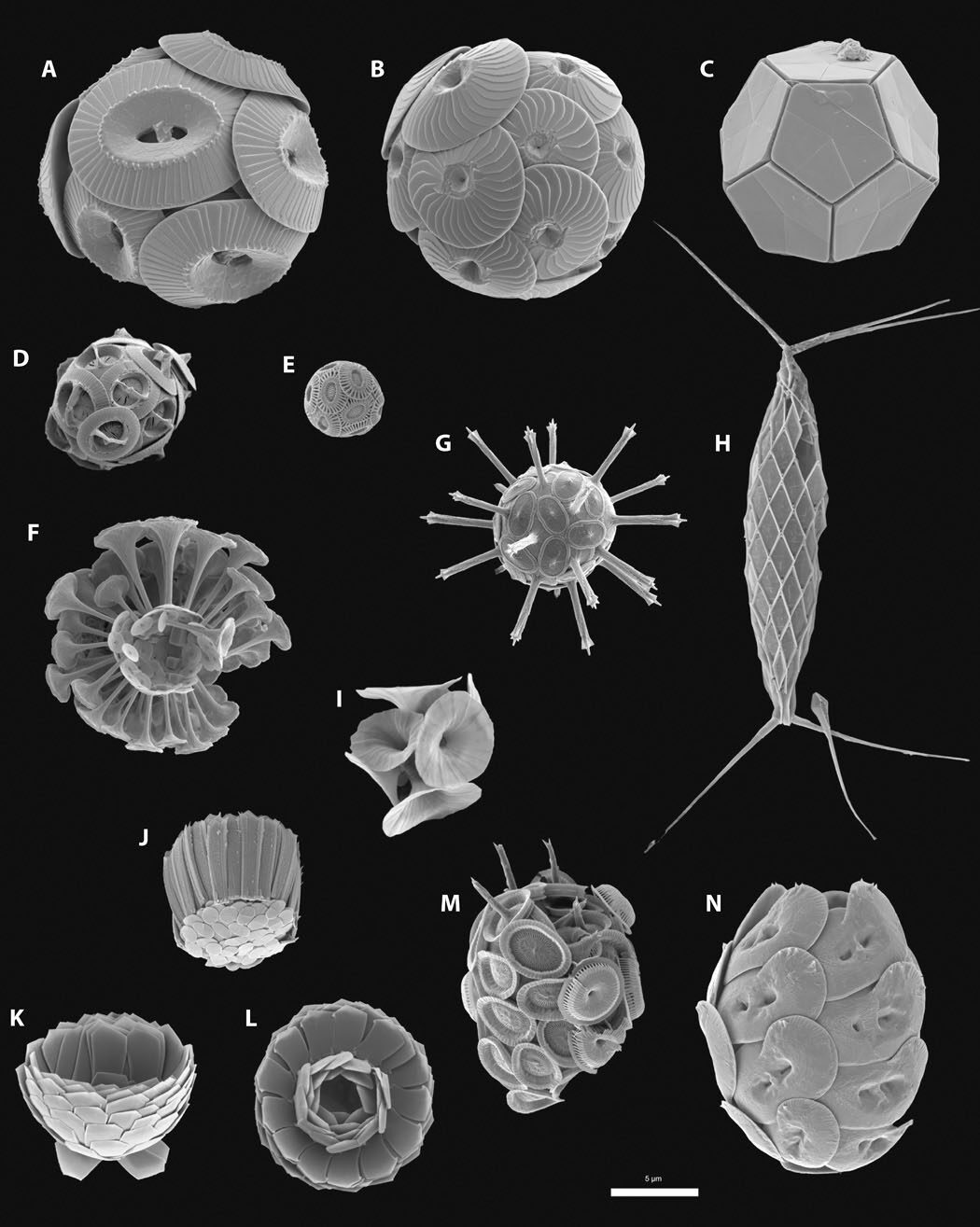

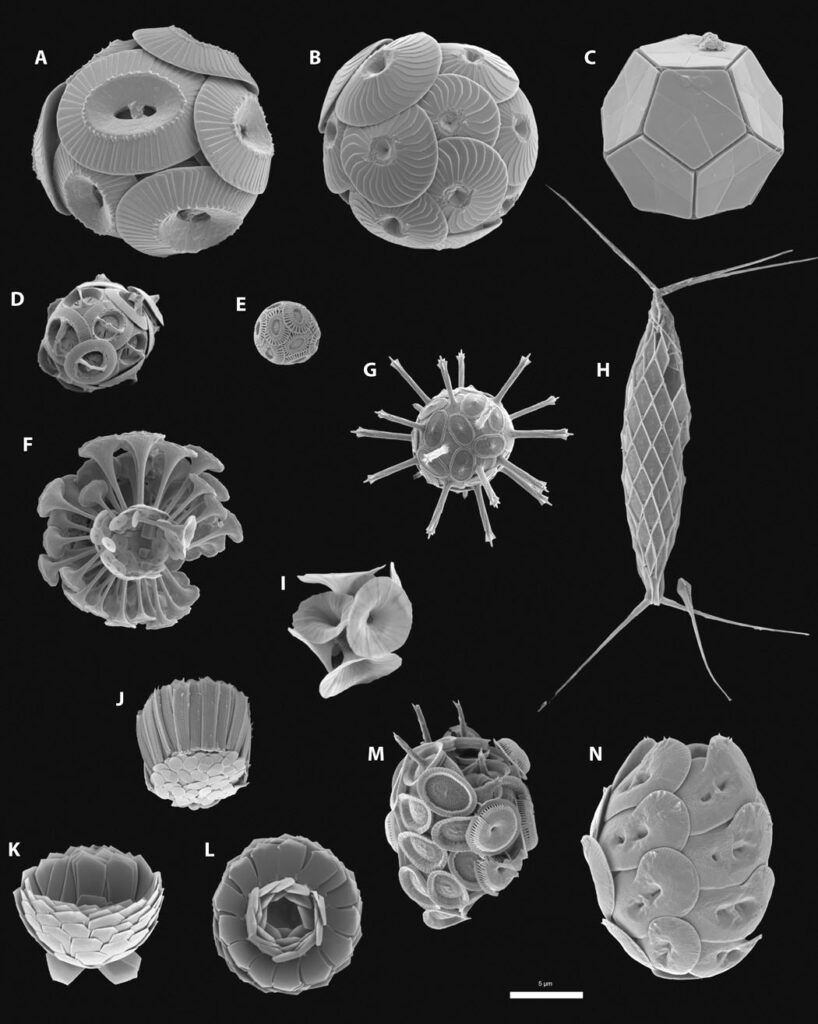

Mao’s research team has consistently been curious about the connection between a material’s architecture and its properties. Yet, this specific endeavor was prompted by an image she encountered of single-celled entities known as coccolithophores, which construct stunning geometric shells from calcium carbonate.

This led her to ponder how these uncomplicated organisms manage to utilize basic components to create intricate configurations. As the investigation progressed, they realized that this approach was not limited solely to coccolithophores.

“There are numerous examples in the natural world,” Mao mentioned. “Geometric frustration serves as one route leading to these astonishing structures.”

Besides offering exquisite aesthetics, the frustration also provided the materials with appealing characteristics from an engineering viewpoint. They could be pliable yet robust and tough, while also displaying gaps within their configuration.

“If we could master the art of building with these attributes, we could minimize material usage and achieve superior mechanical properties,” Mao stated. “It offers us a new perspective on sustainable production.”

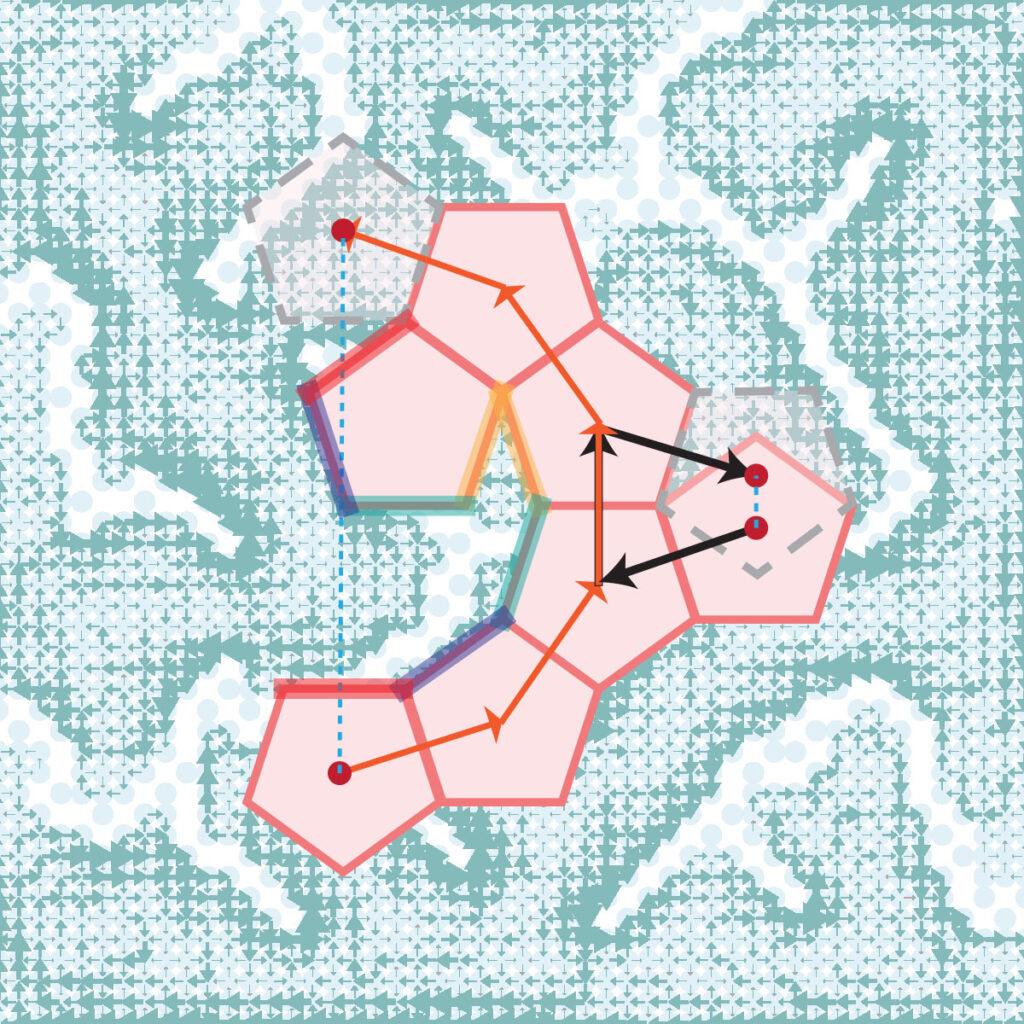

To move forward, the team harnessed a branch of mathematics known as graph theory to explore how architectures can attain the appropriate level of frustration. Their methodology allowed them to develop phase diagrams, which assist in forecasting material properties for varying frustrated designs based on the arrangement of their building elements.

They examined two varieties of frustration, categorized as noncumulative and cumulative. The noncumulative situation resembles the earlier tile example, where some irregularity in the shapes of the building blocks hampers the final design from aligning neatly.

In cumulative frustration, while the building blocks are perfectly shaped, their geometry inhibits them from fitting adequately into the area they intend to cover. Consider the challenge of tiling a flat surface using pentagons as an example.

The researchers found distinctive geometric configurations arising from both types of frustration. In both scenarios, some level of organization among the blocks and gaps was necessary—some measurable pattern—to fully exploit the synergy of utilizing fewer materials offered by frustrated designs. Conversely, there is also a threshold at which the structure becomes overly organized, causing a decline in its material properties.

“Thus, something resembling a simple crystal may not fulfill your requirements, while something utterly disorganized will not function either,” Mao explained.

There exists a Goldilocks zone somewhere in between, she noted.

Mao and her U-M colleagues published their findings in the journal Physical Review Letters. Their team also included Nicholas Kotov, professor of chemical engineering, along with graduate student researchers José Ortiz-Tavárez and Zhen Yang.

The research was funded by the Center for Complex Particle Systems, or COMPASS, a National Science Foundation research center located at U-M. The team aims to advance their work at COMPASS, where future efforts will focus on collaborating with partners to examine real-world instances through the framework of their new models and derive new insights for engineering advanced materials.

“Currently, our research pertains to what we would term a ‘toy model’ in theoretical physics,” Mao noted. “Our ambition is to investigate real materials, and that’s where COMPASS plays a crucial role. Numerous researchers are analyzing actual materials like this, generating authentic data, and employing AI to scrutinize complexities and internal structures of these substances. This is how we will link complexity with functionality.”