Out of the nearly 300 million vehicles operating on U.S. roads, roughly 10 percent are electric. This market is expanding as a result of a growing range of vehicle alternatives and the motivations of drivers to decrease fuel expenses and minimize emissions. Although many electric vehicles available utilize lithium-ion batteries, the costs and ecological effects of lithium extraction are prompting advancements in battery design.

A chemist from Florida State University is part of a national research team addressing these challenges through a significant U.S. Department of Energy consortium established to aid in reducing dependence on critical elements—chemical elements that are highly sought after by various industries yet are in limited supply.

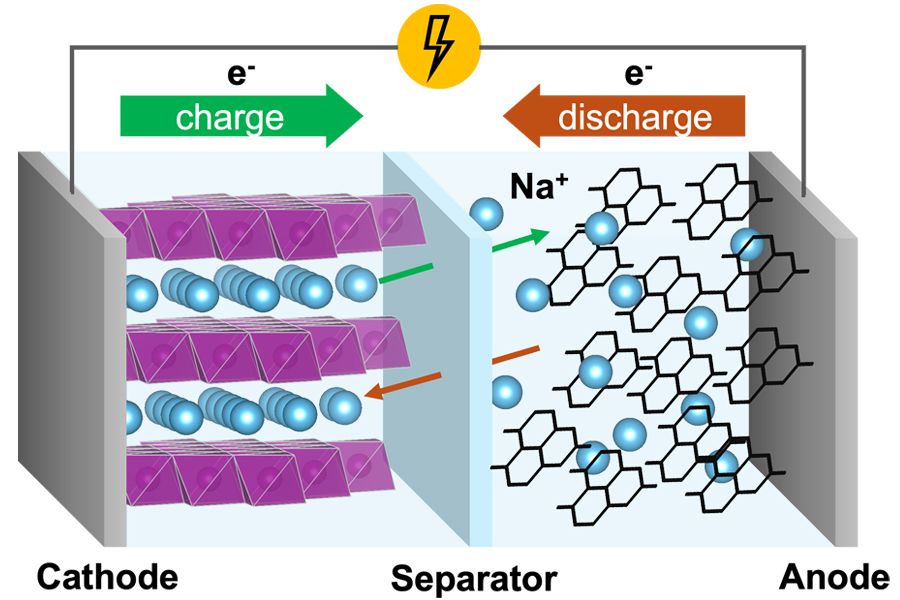

Assistant Professor of chemistry and biochemistry Yan Zeng has received funding as part of the DOE’s $50 million Low-cost Earth-abundant Na-ion Storage Consortium, or LENS Consortium, which seeks to discover, develop, and showcase a new type of sodium-ion batteries designed for electric vehicles. Zeng plans to utilize the more than $300,000 allocated to FSU over the coming years for the development of more efficient cathodes, a crucial element of every battery that dictates how much energy can be stored and delivered to a vehicle. A cathode is the positive side of the battery, where transition metals accept electrons, and reduction reactions take place during the battery’s operation.

“Sodium and lithium share many similarities, and sodium batteries have achieved commercialization in other nations such as China,” Zeng stated. “Nonetheless, there are currently no sodium-ion battery-powered electric vehicles in the United States—this marks the nation’s first substantial endeavor toward affordable, eco-friendly electric vehicles. Additionally, there’s a significant supply chain challenge associated with lithium, and addressing this issue is vital for enhancing the resiliency of the economy’s supply chain.”

This initiative is supported by the DOE Vehicle Technologies Office and unites researchers from six national laboratories and eight universities to devise innovative materials and methodologies to produce potent sodium-ion batteries. Besides its function in producing cathodes, Zeng’s team distinguishes itself through the application of tools such as artificial intelligence and robotic-driven platforms in material synthesis.

“We will employ two different methodologies to synthesize the necessary target materials for creating cathodes,” Zeng explained. “The first is known as solid-state reaction, where we combine various elemental ingredients, such as different metal oxides, carbonates, and other salts, and ‘bake’ them at elevated temperatures within chamber or tube furnaces. Our second approach is solution-based, wherein we crystallize a material from a solution, analyzing the resulting materials to ascertain compatibility. We also have a robotic arm performing repetitive tasks to enhance efficiency, and we utilize AI algorithms to propose parameters that could optimize the results.”

Given that sodium is slightly heavier than lithium, sodium-ion batteries yield lower energy than lithium-ion batteries of equivalent weight and size. Zeng’s team aims to bridge this gap by designing novel element and structure combinations to maximize sodium incorporation within the cathode framework, thus enabling these new sodium-ion batteries to surpass lithium-ion in power. Once these materials with innovative elemental and structural combinations are synthesized and assessed, Zeng and her team will travel to national laboratories to work collaboratively on specialized designs to enhance the cathode alongside other researchers.

“Yan is a trailblazer in the rational design of solid-state materials,” remarked Wei Yang, chair of the Department of Chemistry and Biochemistry. “Due to its chemical intricacy, developing environmentally sustainable and cost-effective sodium-ion batteries is a complex task, and deriving new insights through repetitive operations is often expensive and time-consuming. By integrating AI-informed learning and a robotic-driven platform, as Yan has done, we find a promising answer to persistent challenges, garnering immense national and international attention, and highlighting the department’s strength in our data-driven molecular science progress.”

Other members of the consortium include contributors from the University of California San Diego, the University of Houston, the University of Illinois Chicago, the University of Maryland, the University of Rhode Island, the University of Wisconsin-Madison, and Virginia Tech. Participating national laboratories encompass Argonne, Brookhaven, Lawrence Livermore, Pacific Northwest, the SLAC National Accelerator Laboratory—previously known as the Stanford Linear Accelerator Center—and Sandia National Laboratories.

“It means a great deal to me that I received this funding during my first year at FSU,” Zeng expressed. “I am incredibly grateful to the department and university for assisting me in swiftly establishing my lab and assembling a fantastic team, enabling me to deliver my best contributions to the consortium promptly.”

To gain further insight into Zeng’s work and the research conducted within the FSU Department of Chemistry and Biochemistry, visit chem.fsu.edu.

The article FSU researcher joins $50M Department of Energy consortium to create powerful sodium-ion batteries for electric vehicles was originally published on Florida State University News.