Optical frequency combs are uniquely crafted lasers that serve as measuring tools to precisely and swiftly gauge specific light frequencies. They are capable of detecting and identifying various chemicals and pollutants with extraordinary accuracy.

Frequency combs are particularly suited for remote sensors or portable spectrometers because they facilitate precise, real-time surveillance of numerous chemicals without intricate moving parts or additional equipment.

However, creating frequency combs with sufficient bandwidth for these uses poses a challenge. Frequently, researchers find themselves adding bulky components that hinder scalability and efficiency.

Recently, a group of researchers from MIT has showcased a compact, fully integrated device that utilizes a meticulously designed mirror to produce a stable frequency comb with an exceptionally wide bandwidth. The mirror they engineered, in conjunction with an on-chip measurement system, provides the scalability and adaptability essential for mass-manufacturable remote sensors and portable spectrometers. This breakthrough could lead to more precise environmental monitors capable of detecting several harmful chemicals from trace gases in the atmosphere.

“The wider the bandwidth of a spectrometer, the more potent it is, but dispersion acts as an obstacle. Here we focused on the most challenging issue that constrains bandwidth and made it the focus of our study, addressing every step to ensure reliable frequency comb operation,” explains Hu, Distinguished Professor in Electrical Engineering and Computer Science at MIT, principal investigator at the Research Laboratory of Electronics, and senior author of an open-access publication detailing the work.

Joining him on the paper are lead author Tianyi Zeng PhD ’23; Yamac Dikmelik from General Dynamics Mission Systems; Feng Xie and Kevin Lascola from Thorlabs Quantum Electronics; and David Burghoff SM ’09, PhD ’14, an assistant professor at the University of Texas at Austin. The study appears today in Light: Science and Applications.

Broadband combs

An optical frequency comb generates a spectrum of evenly spaced laser lines, resembling the teeth of a comb.

Researchers can create frequency combs through different types of lasers tailored for various wavelengths. By employing a laser that emits long wave infrared radiation, such as a quantum cascade laser, they can leverage frequency combs for high-resolution sensing and spectroscopy.

In dual-comb spectroscopy (DCS), one frequency comb’s beam directly traverses the system to strike a detector at the opposite end. The beam from the second frequency comb passes through a chemical sample before hitting the same detector. By utilizing data from both combs, scientists can accurately reproduce the chemical characteristics of the sample at significantly lower frequencies, where signals are more readily analyzed.

The frequency combs must possess a high bandwidth; otherwise, they can only detect a limited frequency range of chemical compounds, potentially resulting in false alarms or erroneous results.

Dispersion is the key factor that constrains a frequency comb’s bandwidth. In the presence of dispersion, the laser lines are not evenly spaced, which disrupts the formation of frequency combs.

“With long wave infrared radiation, dispersion tends to be considerably high. There’s no way to circumvent this, so we needed to devise a method to compensate for or counteract it through system engineering,” Hu notes.

Many current methods lack the flexibility required for diverse scenarios or do not support sufficiently high bandwidth.

Hu’s previous work addressed this issue in a different kind of frequency comb utilizing terahertz waves, by creating a double-chirped mirror (DCM).

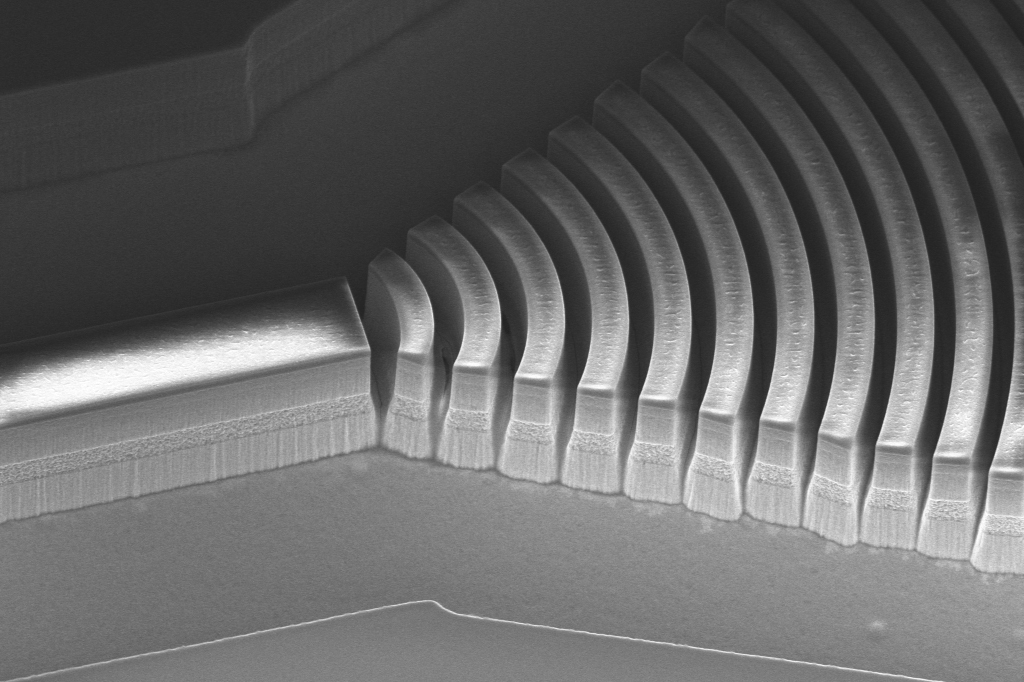

A DCM is a specialized optical mirror consisting of multiple layers whose thickness gradually changes from one end to the other. They discovered that this DCM, featuring a corrugated design, effectively compensated for dispersion when paired with a terahertz laser.

“We attempted to apply this technique to an infrared comb but encountered numerous challenges,” Hu explains.

Due to infrared waves being 10 times shorter than terahertz waves, the production of the new mirror demanded an exceptionally high level of precision. Concurrently, they had to coat the entire DCM with a thick gold layer to dissipate heat during laser operation. Furthermore, their dispersion measurement system, originally intended for terahertz waves, failed to function with infrared waves, which exhibit frequencies that are approximately 10 times greater than terahertz.

“After over two years of endeavoring to implement this scheme, we hit a wall,” Hu states.

A new solution

On the verge of giving up, the team recognized something they had overlooked. They had designed the mirror with corrugation to offset the losses of the terahertz laser, but infrared radiation sources have different loss characteristics.

This realization meant they could revert to a standard DCM design to address dispersion, one that aligns with infrared radiation. Nevertheless, they still had to create curved mirror layers to capture the laser beam, complicating the fabrication process significantly.

“The adjacent mirror layers vary by merely tens of nanometers. Achieving such precision eliminates the use of standard photolithography techniques. Additionally, etching very deeply into the notoriously difficult material stacks was essential. Attaining those critical dimensions and etch depths was pivotal to unlocking broadband comb performance,” Zeng points out. In addition to accurately fabricating the DCM, they integrated the mirror directly onto the laser, resulting in an extremely compact device. The team also crafted a high-resolution, on-chip dispersion measurement system that does not require cumbersome external equipment.

“Our method is versatile. As long as we can utilize our platform to assess the dispersion, we can design and produce a DCM that compensates for it,” Hu adds.

Collectively, the DCM and on-chip measurement system empowered the team to generate stable infrared laser frequency combs with significantly greater bandwidth than typically achievable without a DCM.

Looking ahead, the researchers aim to broaden their method to other laser platforms that could produce combs with even greater bandwidth and higher power for more complex applications.

“These researchers have developed a clever nanophotonic dispersion compensation scheme using an integrated air–dielectric double-chirped mirror. This strategy enables exceptional control over dispersion, facilitating broadband comb formation at room temperature in the long-wave infrared. Their work paves the way for practical, chip-scale frequency combs for applications ranging from chemical sensing to free-space communications,” remarks Jacob B. Khurgin, a professor at Johns Hopkins University Whiting School of Engineering, who was not affiliated with this paper.

This study is partially funded by the U.S. Defense Advanced Research Projects Agency (DARPA) and the Gordon and Betty Moore Foundation.